|

HOW TO SOLDER |

This article

covers all those points missing from all the other HOW TO SOLDER

articles.

1. GET A SOLDERING IRON

Get the cheapest and best soldering iron from eBay.

It costs $12.00 and is temperature-controlled.

It is just like a SOLDERING IRON STATION without the high cost. It does

EXACTLY the same job and there is absolutely no difference in the

quality of the soldering.

You can get 110v and 240v versions. The wattage can be 40 watt or

60 watt. For delicate electronic work it does not matter. The actual

wattage (heat released by the iron) will be less than 15 watts because

it will be turning on and off.

Temperature-controlled Soldering Iron.

It has a poor heat-scale (do not buy)

This iron has a much-better temperature scale (dial)

Don't use the following type of soldering iron. It gets too hot. (The rosin burns off too quickly and it leaves a carbon deposit that prevents the solder sticking to the connection.) The tip gets too hot and and it does not stay "clean."

CHINESE SOLDER

Don't use this type of

soldering iron. It gets too hot!

A Soldering Gun is USELESS for electronic work

It gets too hot and is far too heavy to work-with

2. GET A SOLDERING IRON STAND

Look on eBay for a soldering iron stand. A heavy stand is better than a

light stand. The heavier the better.

This is the type of stand to get. You can put the copper wire sponge in

the tray.

$3.00 to $5.00 posted (from eBay)

This soldering iron stand

comes free with the iron.

But the iron is a "hot" type and NOT recommended

Don't buy any soldering kit as they only supply cheap HOT SOLDERING

IRONS and these are quite unsuitable for electronic work.

3. GET A SOLDERING IRON TIP-CLEANER

You need a copper Wire Ball Sponge to clean the tip as shown below:

See eBay $3.50 posted. Can also be used as a soldering iron

stand

You can also get the "Golden Curls" separately for about $3.00

One bunch will last a lifetime.

It never wears out. Just shake to solder out of the coils.

When you use fine solder, you have almost

NO WASTAGE!!!!!

4. GET A ROLL OF SOLDER

Make sure the solder is 60/40 or 63/37.

It MUST be marked 60/40 or 63/37.

Ordinary tin/lead solder WILL NOT WORK. It melts at a high temperature

and you will damage delicate electronic components.

The solder MUST have flux in the centre of the "wire."

Do NOT buy ACID FLUX solder. It will eat the wires after a few months if

you don't wash it off.

Do not use 1mm solder. It is too thick.

Use 0.8mm solder or 0.6mm or 0.5mm solder. 0.6mm solder or 0.5mm makes the best

connections. You will be amazed at how it improves your soldering.

1mm solder is a WASTE OF TIME. It is too thick. It

leaves rosin on the joints, It leaves excess solder on the iron and is

much harder to use than fine solder.

Fine solder will improve your soldering 200% just by being fine.

This is something no other soldering manual has mentioned. May be the

authors have never soldered in their life !!!

60/40 or 63/37 Solder

About $1.00 posted for 1.6 metres

This photo is 0.8mm but try to get 0.6mm or 0.5mm

Chinese solder

It does not melt.

It does not run around the joint,

It does not harden with a shiny surface and it does not stick the components together - they fall apart !!!

I cannot use it and I have bought 10 different types of Chinese solder and had to throw them out.

You have to increase the temperature of the iron to get the solder to flow properly and it is only good for unimportant connections such as terminal blocks.

I used up 8 rolls by twisting the Chinese solder with good 0.71mm solder and the good solder flowed across the joint with the junk solder and made a good connection.

I will NEVER buy Chinese solder again.

Good 0.7mm solder is made by:

www.cagroup.com.au

and SAVBIT by Multicore Solders (Aust) Pty Ltd

5. GET A ROLL OF

DE-SOLDER WICK

De-solder wick (de-solder braid) is used to "sop up" (remove) solder

blobs and shorts and can help remove the solder from the leads of a

transistor or IC so the component can be removed from the PC board.

The wick contains resin (rosin - the same thing) and the solder flows

into the braid and this is how it is removed from the land (component).

This process always heats up the component and it may be damaged in the

process.

$1.20 posted

Don't pay $3.00 to $5.00 !!!

5. GET SIDE-CUTTERS

Make sure the side-cutters have a spring to keep them

open.

You can get side-cutters like either of these:

About $4.00

About $3.50

THE FIRST THING TO DO IS SET THE TEMPERATURE OF THE

SOLDERING IRON

There are two ways to solder.

Use a very hot iron and solder very quickly - for EXPERTS

or

Use a lower temperature - THE NORMAL WAY TO SOLDER

But, what is the correct temperature?

Here are two ways to set the soldering temperature:

Set the lowest temperature:

All temperature-controlled soldering irons on eBay (for $12.00) have a

temperature-dial, but the simplest way to set the correct temperature is

this:

Turn the dial to the lowest temperature and switch the iron ON.

Touch the solder to the tip - nothing happens.

Now turn the temperature up one division and wait a minute.

Try the solder again. Keep doing this until the solder melts very

slowly.

Now increase the temperature 20°C to 30°C (about one division) and you

have the perfect temperature for delicate soldering. It will melt the

solder quickly but not burn-up the rosin too quickly.

You will find the temperature on the dial will be very close to 370°C

(700°F).

Set the next higher temperature:

This HIGHER temperature allows you to remove the enamel from wires and solder

very quickly.

Increase the temperature slightly by turning the dial above the

temperature you used for the example above.

Add a small amount of solder to the tip of the iron and place the tip on

an enamel-coated piece of wire with

the tip of the iron to make good contact. Wait 10 seconds for the

enamel to melt. If the enamel does not melt, increase the temperature a

small amount and repeat the process.

When the enamel melts, you have the correct setting for fast soldering

and being able to remove enamel from wires.

The temperate on the dial will be very close to 400°C (750°F).

Some servicemen increase the temperature further to do VERY QUICK

SOLDERING, but this is ONLY for EXPERTS.

HERE'S AN AMAZING FACT

Soldering with a high temperature allows you to make a connection very

quickly and the component DOES NOT heat up any more than soldering with

a lower temperature - because you do it VERY quickly.

But a soldering iron without temperature control is TOO HOT and it can

easily damage the components, especially LEDs, transistors and IC's.

Temperature-controlled soldering irons are SO CHEAP. For $12.00 you get

an item to take the place of a $240.00 Soldering Iron Station and it is

just as good.

FACT NUMBER 2

Soldering is entirely to do with CLEANNESS.

Solder will not stick to a dirty wire. It will just "sit there" and the

wire can be pulled out.

Solder does not clean a wire.

It is the resin or rosin in the middle of the solder-wire that cleans

the connection.

But the resin does not work unless it is heated and melted.

When you are soldering, you don't want the solder. YOU WANT THE RESIN.

But the life of the resin is only 1 to 3 seconds before it has

evaporated.

This means you CANNOT transport resin on your iron.

By the time the iron has reached the connection, the resin has

evaporated.

The resin only works when it is heated AT THE PLACE where the connection

is to be made.

That's why the iron must be as clean as possible by pushing it through

the copper-wire ball shown above.

The ball will remove the old solder and clean the tip. Wiping the tip on a

wet sponge DOES NOT CLEAN THE TIP. It just leaves a fine film of

contamination on the tip that is a result of touching the plastic

sponge.

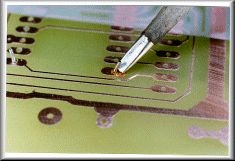

Place the iron on the joint to be soldered and immediately bring 0.8mm

or 0.6mm solder to touch the iron from the opposite side of the

connection.

At this instant you only want the rosin to do its job. Let the rosin melt

and clean the components.

NOW YOU WANT THE SOLDER . . .

Add a little more solder and allow it to run all over the connection and make a smooth and

shiny result.

Remove the iron and don't move the connection for 3 seconds.

Cut or trim the wire with side-cutters at the point where the wire

emerges from the solder. DO NOT cut through the solder and DO NOT cut

the wire before soldering.

Using 0.5mm solder will prevent excess solder remaining on the joint or

on the iron.

Since using 0.5mm solder I have NEVER had to remove excess solder from a

joint or the iron. That's why a spool of 0.5mm solder lasts much longer

than 1mm solder. 1mm solder is too thick!!

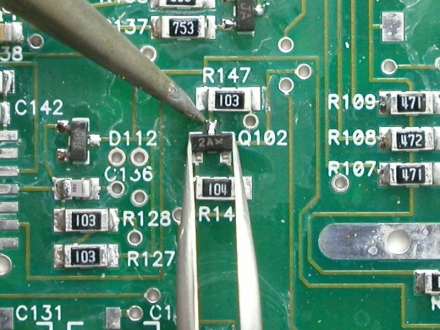

SOLDERING A SURFACE MOUNT COMPONENT

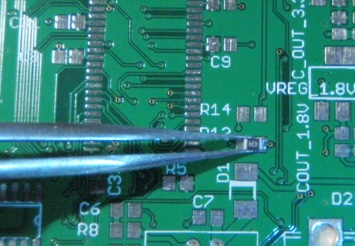

You will need tweezers to hold the component:

The tweezers can be straight or

bent.

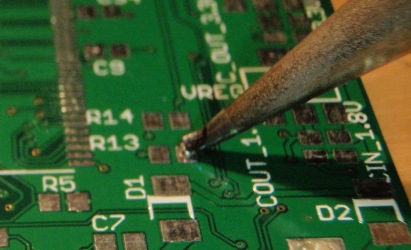

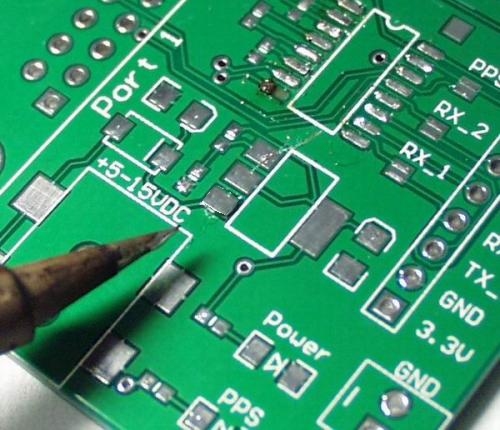

Step 1:

Step 2:

Add a very small amount of solder to ONE pad:

Pick up the component with tweezers with the value of the resistor

showing. (Do not solder the resistor up-side-down as you cannot see the

value!!!! BIG MISTAKE !)

Use the iron to melt the solder that is already on the land and this

will keep the resistor in place.

Make sure the resistor is flat against the PC board by lightly pressing

on it and slowly re-melting the solder if it is tilted or out of

alignment. You can also get the resistor to lay flat by momentarily

releasing the pressure of the tweezers and the resistor will "fall."

Make sure the resistor is square with the sides of the board and exactly

aligned on the lands.

Now solder the other pad. You can re-solder the first pad again and add

a small amount of solder to make a good connection.

Soldering the other land

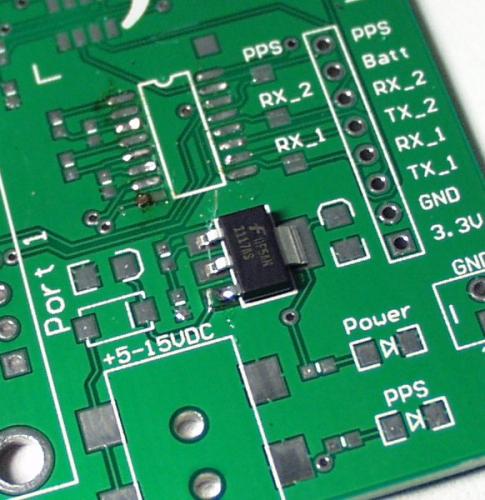

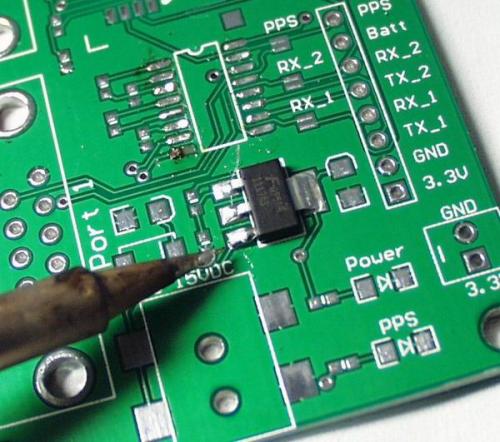

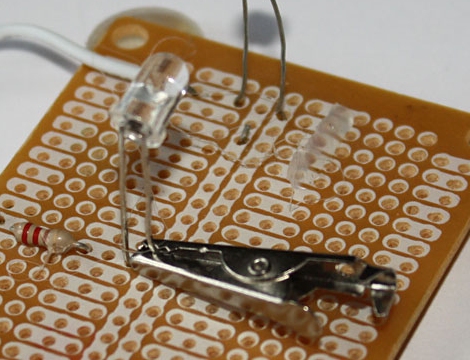

Soldering a Power Transistor

Place the transistor on the lands

and hold it in place with tweezers while re-heating the solder.

Solder all the "legs" ( pins) and "tab."

Re-solder the first leg to make sure it is fully soldered.

The photo shows a clip used as a heatsink to prevent

damaging the LED.

REMOVING SOLDER

Another method is to use a DESOLDER BULB.

These are expensive and the cheap ones don't work because the hole is

not large enough.

You can also use a

solder sucker. This costs

only $2.00 and works quite well.

CONCLUSION

Here is a Chisel point tip (Screwdriver tip)

It is too big for fine soldering

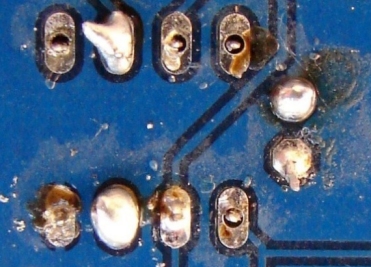

Here are some

messy joints.

If you follow our guidelines, you will not finish up with faulty

connections.

Fine solder is the secret. A temperature-controlled iron is

essential and cleaning the tip on a copper-wire ball will help to

produce good results.

This is not very good soldering.

If you use 0.5mm solder, the joints will improve 200%.

All the PC boards I produce have a solder-mask. This is layer

of green paint (printing) over the tracks so you

don't see the bare tracks (called traces).

Some very good connections and some poor connections

Here are some good soldering joints made with a cheap "hot"

soldering iron. You can see the barrel has got too hot.

You can make good joints with this type of iron if

you work quickly and keep the tip clean.

This diagram shows the wrong way to add solder

to a connection.

Never add solder to the iron. The flux just burns off and is wasted.

The third diagram shows how to add solder to the tag and

push the solder towards the iron to get it to melt.

I don't like "screwdriver" tips.

They are not for

delicate electronic work.

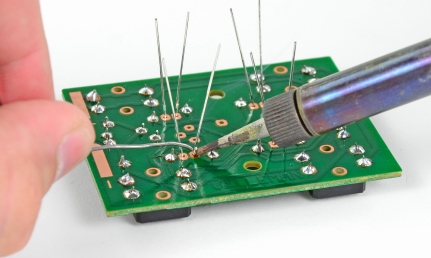

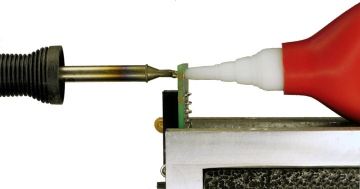

The image shows

the iron ready to place a SMALL amount of solder on one of the lands,

for the Power Transistor. Use a soldering iron with a "pointy tip"

(conical tip). A "screwdriver tip (chisel tip) is not ideal for fine

electronic work. Only a "point tip" will allow you to solder all types

of fine connections.

This will prevent the transistor moving.

Make sure it is touching the PC board.

See the excess solder on the iron. He has not used very fine 0.5mm

solder !!!!

A very small amount of solder has already been placed

on the land and is re-heated very quickly to hold the transistor

in place. The other two legs can now be soldered.

If you follow this article and use a temperature-controlled soldering

iron and 0.5mm solder, you will not need to use a heatsink as the joint

will be soldered quickly.

If you every damage a transistor or LED, you are taking too long.

Here is a "I can Solder" badge kit from the web

for about $3.00 to $6.00

It uses a colour-changing LED and 3v lithium cell

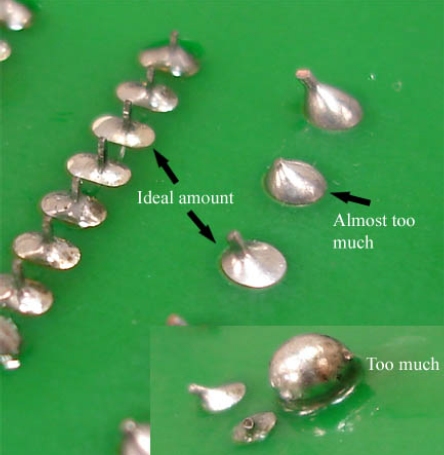

You should not produce blobs and shorts when soldering if you use the

method we have described above. It is virtually IMPOSSIBLE to leave too

much solder on a joint if you use 0.5mm solder.

However a blocked hole will prevent fitting a through-hole component and

the hole must be unblocked.

The quickest and easiest way is to heat the hole (the land around the hole is called

the doughnut or pad) with the tip of the iron inside the hole.

Immediately take the board away and tap it as strongly as possible on

the bench. The solder will fly out of the hole. This

is especially a problem if the hole is "plate-through."

If the hole is on a single-sided board, you can use DE-SOLDER WICK.

Sometimes you can remove the solder from a plate-through hole and remove

the component. It depends on the size of the hole and the thickness of

the wire. Sometimes you can get rid of most of the solder and pull the

lead when the iron is re-heating the joint.

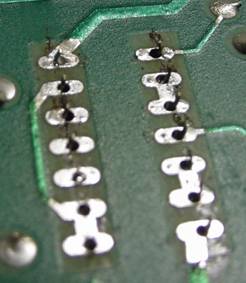

The solder was removed from

the 14 pins with solder wick.

You need to be careful and not overheat the lands as they can

easily lift off the board if overheated.

About $8.00 plus postage

This bulb DOES NOT WORK. The hole is too small

Here is another article on

soldering Surface Mount components and a list of identification codes

for surface-mount transistors and diodes.

Surface Mount

Using and

Soldering SURFACE MOUNT components is quicker, cleaner, easier

and more rewarding than soldering through-hole components.

As soon as you agree, you have mastered SURFACE MOUNT.

The art of desoldering is just as important as soldering.

There are many times when you will want to remove a component from a PC

board without causing any damage.

If you heat the component too much, pull it too hard or wiggle it too

much, the track will be damaged.

Removing a component from a double-sided board that has vias from one

side to the other is slightly more difficult as the hole remains filled

with solder.

You can also get a lot of valuable components from old PC boards:

The fastest way to remove a component is to connect a hook and rubber

band and pull on the component while heating both leads at the same

time.

A loop of string is better as it wont sent the part flying off.

If you are very clever, you can pull on the component while holding the

board and heat the leads. This way you don't need any help from a hook

or string.

If you want to fit another component in the same holes, you will need to

remove the solder from the holes.

This is done by poking the tip of the iron into the hole and making sure

the solder has melted. Now, IMMEDIATELY tap the board on a hard surface

and the solder will fly out of the hole.

Any remaining solder can be poked with a pin as the pin will not attract

the solder.

Multi-leaded components such as IC's and sockets need expensive

solder-pots or hot air guns as you cannot get to all the pins quick

enough.

Another way to clean a hole is to use a needle. Heat the pad and push

the needle though the hole. Some needles do not accept solder and can be

removed quite easily.

And finally another very good method is to use a length of enamelled

wire. Heat the pad and push the wire through the hole. The enamel will

not melt and the wire can be easily removed.

Practice on JUNK boards before working on something you cannot afford to

damage and you will be ready for SOLDERING and

DESOLDERING.

Colin Mitchell

11/10/2022