|

TRACK TESTER |

|

|

This project shows

the polarity of the track as well as providing an indication of the

voltage. You don't need an accurate measurement but it's handy to know

if the voltage is above or below the ideal operating conditions.

You can also see the track is DCC as both red LEDs will illuminate

and the piezo will produce a tone.

The kit costs less than a ready-made product and has more features.

Here is a Track Tester on eBay. It just shows the voltage on 3 LEDs and

costs $18.00:

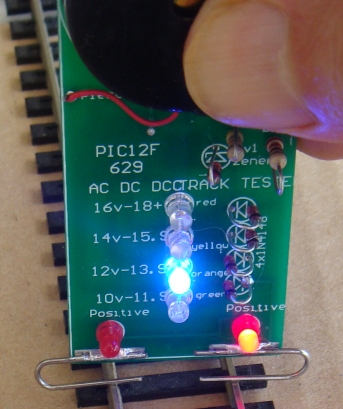

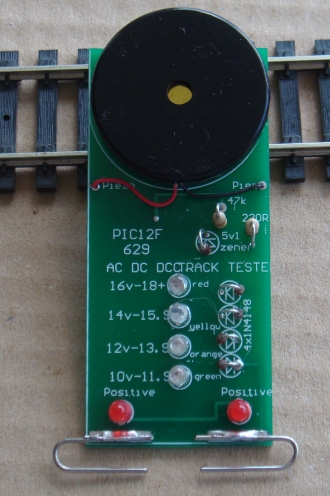

Track Tester showing the voltage

and polarity

Close-up of TACK TESTER

Our kits has more features and costs $14.50 posted.

THE CIRCUIT

CONSTRUCTION

U

PROGRAMMING

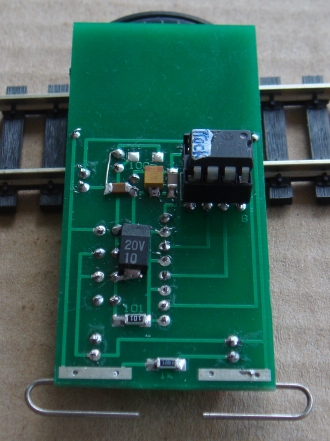

Back of tester showing the

microcontroller

and surface-mount components

THE LEDs

The voltage on the track is shown by a set of

4 LEDs. You don't need to know the exact voltage but if the voltage is

higher than 18v you need to be aware as this will damage some

electronics modules and below 10v will indicate a fault somewhere in the

system.

The LEDs are arranged in 2v increments and two LEDs will flash when the

voltage is between two LEDs:

The 16 - 18v LED flashes when the

voltage is higher than 18v.

Two LEDs flash when the voltage changes

from one LED to the other.

No LEDs illuminate below 10v.

The circuit has two red LEDs to indicate the positive track and a

voltage detector to convert the voltage to one of the LEDs in the BAR

GRAPH. This means you can put the tester around either way and

will produce the correct results.

Our project is quicker and more convenient to measure the voltage with the

spring-contacts.

The project is

The other Loud Mobile Ring

Circuit

Place the tester on the rails and the springy terminals will

make contact. One of the red LEDs will illuminate and one or more of the

LEDs in the BAR GRAPH will indicate the voltage.

The piezo diaphragm will buzz or hum if the track is DCC.

It will also buzz if the track is DC but has a lot of "ripple." This

means the smoothing electrolytics in the power supply are not working to

produce SMOOTH DC. This may be the reason why DC motors are "humming"

This project is part of a PIC

microcontroller course to teach programming.

The kit comes with a pre-programmed microcontroller and you just have to

solder the kit and it is ready to work.

However there are a number of constructors who will be using this

project to help them understand how to program a microcontroller and

this section is part of the PIC micro course.

Before choosing a PIC we tried zener diodes and resistors to turn ON the LEDs

at different voltages, but the result was very poor. It was very

difficult to get them to turn ON at the desired voltage and turn OFF at

a higher voltage.

We could have used a LED BAR GRAPH chip but it does not have the

flashing feature to show when the voltage is midway between each range.

A micro is small, cheap and is a lot more versatile and anything else.

All you have to do is write an A-to-D program to detect the voltage.

This requires just a single input/line, a 100n capacitor and a high

resistance resistor.

The micro discharges the capacitor at the beginning of the cycle then turns the line into an INPUT.

It then calls a very short delay and looks to see if the

capacitor has charged to about 3v. This voltage is detected by the micro

as a HIGH. If the input line is not HIGH, the program calls the short

delay again and looks for a HIGH.

A file is incremented every time the delay routine is called.

The lowest voltage we need to detect is 9.9v and this resulted in about

40 delay loops. As the voltage is increased, the number of delay loops

decreases, so that 18.9v resulted in 19 loops.

The whole secret to setting up this "test-routine" is to get a delay

routine that is short-enough to result in about 4 loops for every volt

increase.

We used an adjustable voltage bench power supply and the delay routine was shortened until we got about 4

loops for each volt. This allowed us to detect

each 250mV increments.

Once we have a table of loops for 9.9v to 18.9v we had values from 19 to

40.

All we have to do is put these values into a sub-routine so that each

value produces a result on the "bar graph."

You must remember this: You do not know what value will be produced by

the micro so all values must be handled and a result on the display must

be produced. Otherwise the micro will jump to the wrong part of the

program.

The value of loops we get is called RAW DATA and we must "clean it up"

by removing the values 1 -19. The first instruction subtracts 19 to get a result of ONE to TWENTY.

This means we now have to allocate 20 values to the display in which the

the value of ONE represents 18.9v.

Every value

must go to a LED or a pair of flashing LEDs.

We now decrement "loops" and if it zero, we know the result is 18.9v.

This means we flash the top LED.

If the answer is not zero, the micro goes down the sub-routine and

decrement the value again. If it is zero, the top LED is turned ON.

The sub-routine keeps decrementing "loops" and turning on one of the LED

or flashing two LEDs, until "loops" is decremented to zero.

|

|

|

20/1/2015