|

Prototyping Boards |

Working with

Prototyping Boards

Boards are available from

Talking

Electronics.

![]()

It doesn't matter if you are designing a new

microcontroller project or a simple transistor amplifier, the first

necessity of designing a project is the ease of

changing components.

If you think a project will work without testing, modifying and

altering things, you are kidding yourself.

It sometimes takes hundreds of changes to get a project working

perfectly.

And if the components are not easy to change, you may be reluctant to do

the finer adjusting.

That's why a prototyping board must be designed for easy access and must

be universal, so that all types of components can be fitted.

Here are 4 prototyping boards from Talking Electronics:

Matrix Board MkIII

Matrix Board MkIV

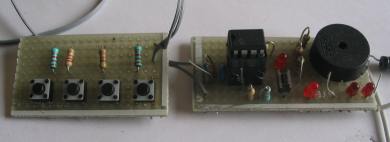

Prototyping boards are not designed to look aesthetic. They are designed

to be functional and reduce frustration.

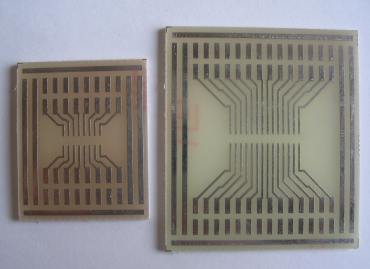

Two surface-mount boards from

the range from Talking Electronics

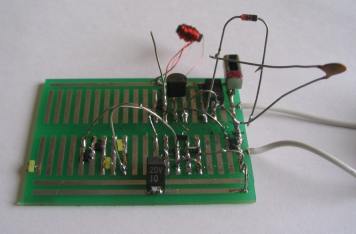

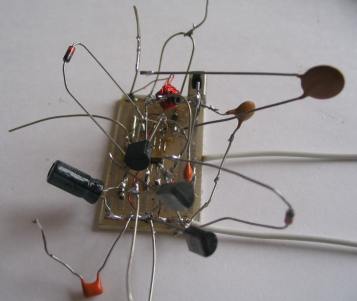

A prototype project is sometimes called a "rats-nest" or "birds-nest."

There are two levels of prototyping.

The first level requires no experimenting. It's simply building a

"proven" circuit on a board and connecting it to other items.

The second level involves experimenting and changing component values.

For this, the components should be on one side of the board.

The end-result is a jumble but it's the only way to be able to get

to everything:

11 LEDs and surface-mount components

design and before the final board

Many prototyping boards on the market are quite useless. They are not

really prototyping boards but rather "Universal Boards" that will accept

different components and hand wiring.

Using a Matrix Board for designing

The essential part of a prototyping board is the accessibility of each

and every component so that voltage and waveforms can be measured.

But the most important reason is each component must be easily removed

and/or replaced. That's why soldering components though holes is not

suitable. Sometimes a component has to be changed 4 or 5 times. Imagine

the difficulty of pulling out a component every time you want to alter

the value.

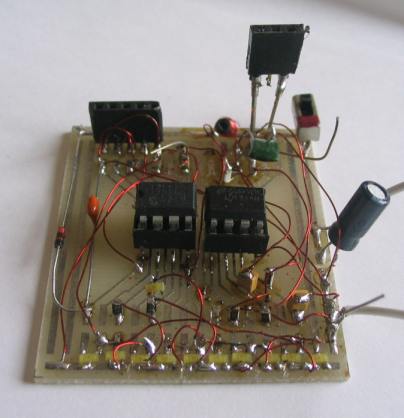

Some of our prototype boards have certainly become over-crowded but

that's how a circuit gets designed.

Initially you think the circuit will need a few components and choose a

small PC board. It quickly gets over-crowded but as the circuit

develops, you can easily see what each component is doing and it's

really not complex at all.

You will notice many of the circuits in the photos above have been

designed with surface-mount components.

These are just as cheap as normal components and since they take up less

space on the board, it creates less clutter and you can see what you are

doing.

Surface-mount

kits are available from Talking Electronics and when combined with

the prototyping boards, you will be able to develop circuits that are

very compact.

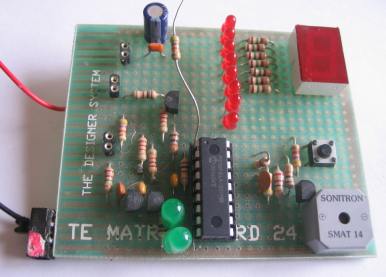

The second step before making a PC board is to lay out the components on

a matrix board in the same locations as they will appear in the final

design.

This will give you two answers. It will let you know if the project will

work and give you some idea of the size of the board and where each item

is positioned. The underside of the board is generally a mass of fine

wiring and it may need one more layout to produce wiring that does not

cross at any location. Any wires that cross each other need a jumper and

by carefully re-laying the board, no jumpers will be needed. Here is our

example of the PIC Lab-1 before the final PC layout. The stage before

this was a "rats-nest" and the final design you can see in the PIC Lab-1

article.

If you think our projects "magically appear from no-where" you should

see our boxes of thousands of prototypes!

The second step to making a PC

board

2/11/07