|

The

Transformer

All you need to know about

the transformer. . .

INDEX

Page 54

The symbol for a power transformer can be any of the

following:

The

number of loops in the symbol does not indicate the relative size of the winding

however it is handy to show some sort of comparison so that you can see what

the transformer is doing.

The only reason why the secondary may be drawn larger than the primary is

to fit in with the other symbols on the circuit diagram.

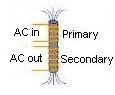

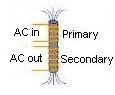

The animation below shows the "Mains" entering the primary of a

transformer and the resulting waveform on the secondary. The shape of the mains

voltage is called a sinewave and the output will reproduce this shape and have

an amplitude according to the ratio of the turns on the primary to the

secondary.

As more turns are added to the secondary, the voltage

increases. If

the turns on the secondary is less than the primary, it is called a STEP-DOWN

transformer. If the secondary has more turns than the primary, it is called a

STEP-UP transformer. If the turns are equal it is called an ISOLATING

transformer.

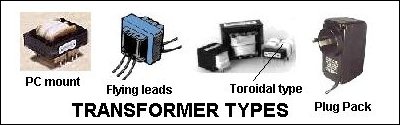

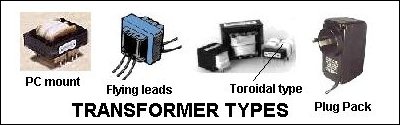

TYPES OF TRANSFORMER

There are thousands of different types, styles and sizes of transformers on the

market. The diagram below shows some of the types we are covering in this discussion:

USES

A transformer can provide more than 30 different features in a circuit, and sometimes it is

providing 3 or more at the same time.

Here are some of the features it can provide:

1. Isolating one voltage from another,

2. Increasing the voltage,

3. Decreasing the voltage,

4. Increasing the current,

5. Decreasing the current,

6. Providing a phase reversal,

7. Providing a phase shift,

8. Providing a feedback voltage or pulse,

9. Electromagnetic radiator,

10. Electromagnetic detection,

Plus a lot of effects when combined with other components, such as:

oscillators, filters, signal boost, signal attenuation and lots more.

The diagram below is a simple transformer wound on a soft-iron or ferrite core.

If AC is applied to the primary, a voltage will appear on the secondary. This

type of transformer is not as efficient as one with a "complete magnetic

path" - however it does work.

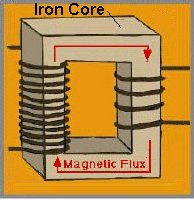

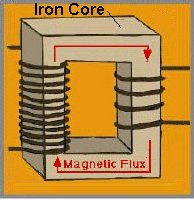

If

the magnetic path is complete as shown in the diagram below, more energy is

transferred from the primary to the secondary, via the magnetic flux. The

magnetic flux moves clockwise (it is called EXPANDING FLUX) during the

first half of the cycle and in a counter-clockwise direction (called DECREASING

or COLLAPSING FLUX) during the second half of the cycle.

THE

POWER SUPPLY TRANSFORMER

In this section we will discuss the transformer in its role as a POWER TRANSFORMER in a POWER SUPPLY.

The transformer

plays a very important part in producing a successful power supply but it is a component we

tend to know

very little about.

Very few specifications are provided with a transformer and quite often these are over-rated.

There are a number of specifications you need to know when using a

transformer and the only way to find them out is to build an experimental

circuit. A transformer works very well until you need to use its full output.

That's when you find things go wrong.

Take for instance, current rating. How many times have you seen two different

transformers. One is larger than the other but they are both rated 12v @ 500mA.

There are a number of reasons why this can be true - or seemingly true.

It's all in the way you test the device. No matter how you see it, it's always best to

go for the larger transformer. There is no way a manufacturer can

put extra "power" or "punch" into a smaller unit and

get a "boosted" output - unless the transformer is different design.

The 500mA rating for the smaller transformer

may be for a very short period of time or the transformer may have a slightly higher

output voltage so that when the full 500mA is drawn, the output voltage will

fall to the specified value.

The main problem with this is the higher voltage is passed to the input of your

power supply and must be dissipated in the regulator as "wasted

heat." This reduces the efficiency of the power supply because the

regulator is already getting very warm and when a higher current is required,

the regulator may shut down. In addition, the transformer runs very hot because

it is delivering more voltage (and thus more wattage) than needed.

This is an extreme example but is exactly what happens in reality.

The smaller transformer is said to have POOR REGULATION and is not the best

type to use.

Obviously the best type is one that is slightly larger than

required so that it runs cool.

Again, all the mathematics in the world will not beat the simple task of

feeling the transformer after it has been operating for 30 minutes or so.

Again, there are two checks to be made. Check the transformer after 30 minutes

of no load and again after 30 minutes of full load. What could be simpler. I

could provide you with a 2-year course on transformer-design, or a 10 second

test to check the temperature. Basically, if the transformer is getting too hot

on no-load, the flux density in the core is too high. It works like this: As

the input voltage rises, the primary turns produce a magnetic field and this

field passes through the magnetic material in the centre of the coil, called

the CORE. The field turns "little magnetic dipoles" in the core and aligns

them in a particular direction. These magnetic dipoles then have the effect of

producing a magnetic field in the opposite direction to produce a reverse

voltage that is almost the same magnitude as the incoming voltage.

If the incoming voltage is 130v, at a particular instant, the voltage produced

by the transformer may be 125v and thus the forward voltage is really only 5v.

This is an amazing situation but is exactly what happens. For this to occur you

don't need any secondary winding. It can be removed and exactly the

same result will occur.

Now we come to the reason why some transformers get hotter than others.

There are two reasons.

The material in the core is iron (called soft iron) and this is a conductor of electricity. As the

magnetic flux passes through the core, it is not absolutely uniform and any

non-uniformity allows a small voltage to develop from one area to the other and

this voltage causes current to flow. The core material is sliced into thin

sheets called laminations to create a very long path and thus a high resistance

is created so that the actual current flow is as small as possible. However a small

current does flow and this causes some warming of the core.

But the major warming comes from the primary winding.

As the primary voltage increases, more and more magnetic dipoles align in a

direction to produce a reverse or "back" voltage. But there comes a

time when there is no more magnetic dipoles, and the reverse voltage does not

keep up with the incoming voltage. The difference between the two voltages

increases and thus by simple Ohm's Law, the primary current increases due the

resistance of the primary winding. This increased current only occurs during the peak of each waveform

and that's how the transformer gradually warms up - the primary winding gets

hotter and passes its heat to the core.

When a load is applied to the transformer, the magnetic flux produced by the

primary winding cuts the turns of the secondary and induces a voltage in each

turn. This

voltage is the "pressure" that allows a current to flow in the

secondary circuit. The magnetic flux is passed to the secondary winding and does

not have time to activate as many magnetic dipoles. Thus the "back"

voltage is not as high and more current flows in the primary winding. If we

take more current from the secondary, the primary draws more current from the

"mains."

DESIGNING

A TRANSFORMER

We are not going into the design of a transformer as this is

beyond the scope of

this discussion. There are plenty of transformers on the market to choose from

and you cannot build one cheaper than the ready-made item.

WHAT'S THE

ADVANTAGE OF A CENTRE-TAP?

There is basically two

types of output windings. One is a single winding and the other is tapped.

Before we discuss the advantages of the single winding, we need to go into some

theory.

The most efficient transformer has half the bobbin wound with the primary

winding and half with the secondary. This allows the largest gauge wire to used

for each winding and thus the "copper losses" are the least.

"Copper loss" is the heat generated in the winding due to current

flow. A winding delivering 1 amp gets much hotter than an ordinary piece of wire

carrying 1 amp because the winding is GENERATING the current and lots of

"eddy currents'" are flowing in the wire. These can be thought of as

currents flowing is the wrong direction, but eventually enough current flows in

the right direction to create 1 amp. If the wire is thick, the resistance of the

wire is low and it does not get as hot as thinner wire.

Now we come to the comparison of a single secondary connected to a full wave

rectifier (4 diodes) and a centre-tapped secondary connected to 2 diodes.

The diagram below shows

these two arrangements.

A single secondary winding Vs centre-tapped

secondary

In

the diagram, we are assuming the output is the same in both cases, (such

as 12v @ 1 amp). In the first case, the secondary is delivering current to the load via

diodes b and c in the first half-cycle and via diodes a and d in the second half

of each cycle. This puts a load on the winding of two pulses of energy per

cycle. In addition, there is a drop across two diodes.

In the second case, winding A delivers current to the load via the top diode

during the first half of each cycle and winding B delivers current to the

load via the bottom diode, during the second half of each cycle. Each winding has a

short period of rest-time between pulses of energy.

The question is: Which circuit is the best?

The answer is circuit 1.

The centre-tapped circuit has some advantages but overall, Circuit 1 is the

better choice.

The centre-tapped transformer is basically delivering energy from half the

secondary space on the transformer at each half cycle and thus the

winding is a thinner gauge (to fit in the space) and will get slightly hotter

than the single-secondary. The result is the

centre-tapped transformer has to be "driven harder" to deliver the

same output current as the single secondary transformer.

In the diagram below, the circuit is a combination of a bridge rectifier and a

7805 voltage regulator. Click the pieces and they will change places.

A 7805 1-Amp Power Supply

To unscramble, you need IE 4 or

later.

Click two pieces and they change places.

MOUNTING

There are three ways to mount a transformer.

1. Mounting lugs or tags. The transformer will have either flying leads

or solder tags.

2. Printed Circuit board mounting. The transformer will have pins to go

through holes in the PC board.

3. Toroidal transformers have a mounting screw that goes through the

centre of the transformer and screws to a base-board.

Only mount very small transformers directly onto a PC board - large transformer

will break the trackwork. This form of

mounting is very dangerous as the mains connections are exposed on the underside

of the board. It is also very difficult to fit the board into an enclosure, with a

heavy transformer sitting on one end.

CONCLUSION

The answer is simple. If you are designing a power supply, collect (or buy) a

range of transformers and test them on your project. Feel the temperature after

a period of time and check the current capability by loading each device with

the required current. You can even draw slightly more current during the

"test" to determine if the transformer is operating at its maximum, or

if there is a little extra current in reserve.

Don't take manufacturers specifications as factual. Most specifications are

either "guessed" or exaggerated. It's a bit like the output rating of

a stereo systems. How can an amplifier produce 100watt output if the power

transformer is rated at 12v @3.5 amp?

The size (and weight) of a power transformer is a very close indication of its

VA (Volt-Amp) rating. This is the AC output Voltage multiplied by the output

current (Amps).

Simply get a range of power transformers and note their VA rating.

The VA rating is not a linear scale. In other words, if a transformer is

increased to double the weight, the VA rating can increase by more than double.

This is because larger transformers have a higher efficiency rating.

Note the size of the wire in the secondary. It should be as thick as possible.

Also note the way the transformer is made. It should be "potted" to

prevent the windings and laminations moving and vibrating during operation.

As I said. The answer is simple. Feel the transformer after 30 minutes of operation.

If it "smells" or feels too hot, replace it with a larger design.

See Page 2 for more on the transformer,

including the secret to making a transformer with a very high output current.

NEXT

|