|

LED TORCH CIRCUITS |

This project illuminates a white LED and

explains how a transformer works . . .

Page 1

|

Conventional torches come in all shapes and sizes. |

|

White LEDs have different "characteristic voltages." A 1,000mcd white LED used in this project had a characteristic voltage of 3.5v and a 3,000mcd white LED had a characteristic voltage of 3.2v. Both LEDs were driven at 20mA and the 3candala LED produced a brighter, whiter light while the 1candella LED had a yellowish ring around the edge of the illumination. |

A LED torch is one of the simplest projects you can

build and it's very interesting as it uses a super-bright

white LED.

In the history of LED production, red LEDs were the first to be invented and

their output was so dim you could barely see if they were illuminated. You

needed a darkened room to see them at all.

Then came green, yellow and orange LEDs.

As time went by, the brightness improved and it came to a point

where the output would shine into the surrounding air. These were called

Super-bright LEDs.

Then came the blue LED. At first it was dull, but gradually the output increased

to a dazzling glare.

With the combination of red, green and blue, manufacturers had the potential of

producing a white LED.

This was the dream of all LED manufacturers.

Since the illumination produced by a LED comes from a crystal, it is not

possible to produce white light from a single crystal or "chip."

The only way was to combine red, green and

blue. As soon as the output of blue came up to the quality of the other colours, a white LED

was a marketable product.

The more-recent way to produce while light is to illuminate a blue LED and

surround it with a yellow phosphor coating. The yellow and blue combine to

make white light. This is called additive mixing of colours.

White LEDs are now with us and their output makes them a viable alternative to

the globe.

There is an enormous array of LED torches on the market, from $2.00

"give-aways" to $200 "rip-offs."

Although a LED torch is passable for illuminating an area, it certainly does

not have the illuminating capability of a $10 lantern, using a 6v battery.

A LED torch is more of a "fun-thing" to see how far LEDs have come in the past

few years and see what can be done with a single cell and an handful of

components.

When we first decided to produce a LED torch project, we wanted to fit the

circuit into a 2-cell torch but a white LED requires about 3.4v to

operate, and two cells produce only 3v. So we had to think of a number of ways

around the problem. That's why we have produced a number of circuits.

As you know, a LED will not operate on a voltage below its characteristic

voltage. It simply will not operate AT ALL.

This characteristic voltage depends on the type of LED and is about 1.7v for a

normal red LED, while a super-bright LED is about 3.1v - 4v.

The exact characteristic voltage varies with the colour, the

intensity of the LED, the current flowing and the way it is

manufactured. This feature cannot be altered after it is manufactured and the EXACT voltage must be

delivered, otherwise the LED will be not work or if the voltage is higher, it

will be destroyed. This is the cold, hard fact. The supply voltage must

exactly match the characteristic voltage.

This sounds a difficult thing to do, but a simple solution is to add a

resistor in series and the voltage across the LED will sit at the exact value

required by the LED, while the extra voltage will appear across the resistor. According to Ohm's Law,

a current will flow though the resistor and this will also flow

though the LED. This applies when the circuit is supplied with a DC voltage.

All we have to do is create a voltage higher than 3.4v and we can drive one of the latest

SUPER-HIGH-BRIGHT white LEDs with a single cell, using a step-up-voltage

circuit.

This will produce a series of pulses to the LED and the brightness will be

slightly higher than if a steady DC voltage is applied. These are the things

we will be covering in this project.

|

This project explains the operation of a "transformer" in flyback mode. A transformer is one of the most complex items in electronics. Even a simple hand-made "transformer" requires a lot of understanding to see how it works. This project will demystify some of the features. |

JOULE THIEF

The web is filled with circuits similar to "CIRCUIT A"

below.

Here are 3 circuits:

Although they work, the performance and efficiency can be

increased an amazing 300% by simply adding a capacitor.

Here is a circuit from one of the major chip manufacturers:

Apart from the circuit being enormously complex and expensive, 62mA is too high

for many white LEDs. The maximum current must be kept to 20 - 25mA.

The first "poor design" got me thinking. Maybe the signal at the transformer

end of the 220R needs to be stabilised to improve the performance of the

circuit. I tried a transistor and it did not work.

The brightness of the LED did not alter but the current changed from 85mA to

28mA.

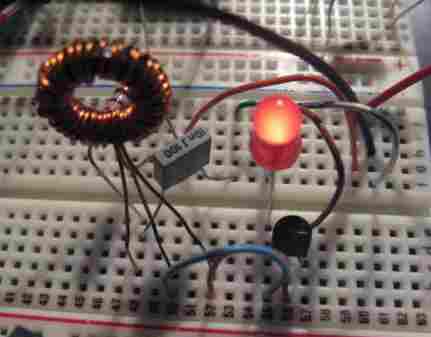

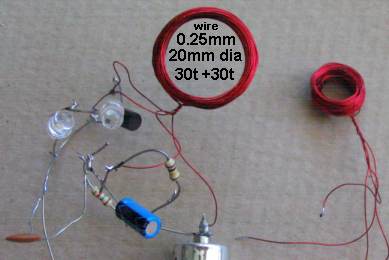

Here is a photo of Circuit B constructed by a reader. He used a toroid (a

circular magnetic circuit - or ring) and this has lower losses because the

magnetic flux does not emerge (come out of) the end of the core. The

magnetic flux keeps circulating. However if the flux is not very high, it

does not saturate the core and there are no losses and the slug performs

almost the same as a toroid.

We will look at the Joule Thief circuit and show the improved design.

CIRCUIT A

The first circuit in this discussion is the simplest design.

It consists of a transistor, resistor and transformer, with almost any type

of LED. The circuit will drive a red LED, HIGH BRIGHT LED, or white LED.

The circuit produces high voltage pulses of about 40v p-p at a

frequency of 200kHz.

Normally you cannot supply a LED with a voltage higher than its

characteristic voltage, but if the pulses are very short, the LED will

absorb the energy and convert it to light. This is the case with this

circuit. The characteristic voltage of the LED we used was very nearly 4v and this means the voltage across

it for a very short period of time was 4v. The details of the transformer

are shown in the photo. The core was a 2.6mm diameter "slug" 6mm long and

the wire was 0.95mm diam. In fact any core could be used and the diameter of

the wire is not important. The number of turns are not important however if

the secondary winding does not have enough turns, the circuit will not

start-up.

HOW THE CIRCUIT WORKS

The transformer is configured as a BLOCKING OSCILLATOR and the cycle starts by

the transistor turning on via the 2k7 base resistor.

This causes current to flow in the 60-turn main winding. The other winding is called

the feedback winding and is connected so that it produces a voltage to turn the

transistor on MORE during this part of the cycle.

This winding should really be called a "feed-forward" winding as the signal

it supplies to the transistor is a positive signal to increase the operation

of the circuit. This is discussed in more detail in

Circuit Tricks.

This voltage allows a higher current to flow in the transistor and it keeps

turning on until it is saturated.

At this point the magnetic flux produced by the main winding is a maximum but it is

not expanding flux and thus it ceases to produce a voltage in the feedback

winding. This causes less current to flow into the base of the transistor and

the transistor turns off slightly.

The flux produced by the

main winding is now called

collapsing flux and it produces a voltage in the feedback winding of

opposite polarity. This causes the transistor to turn off and this action

occurs until it is

completely off.

The magnetic flux continues to collapse and cuts the turns of the main winding to produce a very high

voltage of opposite polarity.

However this voltage is prevented from rising to a high value by the presence

of the LED and thus the energy produced by the collapsing magnetic flux is

converted to light by the LED.

The circuit operates at approx 200kHz, depending on the value of the base

resistor and physical dimensions of the transformer.

The circuit draws 85mA from the 1.5v cell and the brightness of the LED was

equivalent to it being powered from a DC supply delivering 10 - 15mA.

Before we go any further, there are a number of interesting circuits on the web.

The following two circuits need explaining. The first circuit is identical

to our "Circuit A" except the design engineer did not do his homework. He

only added 8 turns to the 100uH inductor and found the circuit did not

start-up. His solution was to add another transistor and tie the base to the

collector. What a waste of a transistor!

The second circuit is a very inefficient design. The second transistor is

being turned on via a 1k resistor on the collector of the first transistor and when this "turn-on" current is not

required, it is being shunted to "deck."

Our circuit uses the "oomph" of the secondary winding to saturate the

transistor and this produces the highest efficiency.

But I actually thought of placing a small capacitor at the join and taking

the other end to the 0v rail. This will allow rail voltage to enter the

feedback winding of the transformer but prevent the signal generated by the

winding being lost through the 2k7 resistor.

The following circuit is the result:

The circuit instantly became 300% more efficient.

I could not believe it.

When I put the CRO across the LED, I realised why. The frequency of the

circuit changed from 200kHz to 500kHz. The LED was getting more than twice

the number of pulses per second.

That's why you cannot trust anything or anyone. This improvement has never

been presented in any circuit on the web. Obviously no-one has done any

experimenting at all.

If the brightness of the LED is equal to a DC voltage of 4v and a current of

10mA, the circuit we have produced is slightly more efficient than

delivering a DC voltage to the LED, even though

there are some losses in the transformer and transistor.

This proves the fact that LEDs driven with a pulse, are more efficient than

being driven by a DC supply.

The original 30 turns + 30 turns coil is

shown on the right. The circuit took 20mA to illuminate two LEDs.

The circuit can be made small by using a

ferrite slug 2.6mm diam x 7.6mm long.

2-TRANSISTOR CIRCUITS

In the circuit above, the base current is constant and will be very small

through a 10k resistor.

The circuit turns ON via the 220k resistor and the voltage on the collector

of the NPN transistor drops to nearly 0v. This action causes current to flow

through the inductor and at the same time the 1n capacitor is brought

towards the 0v rail and this turns ON the first transistor slightly harder.

This action continues until the driver transistor cannot be turned on any

more.

This circuit is designed for mass production as the choke is a standard

33uH.

With this we turn to a surface-mount chip that has been designed to carry

out the exact same task as circuit B. The chip is called PR4401. The

following is the promotion advert for the chip:

I could not find any sales literature on the internet, but the manufacturer

requires 9,000 pieces to be bought at a cost of 36 cents per piece. This

comes to $3,240 if you want to incorporate it into your project.

LED TORCH - JOULE THIEF - INDUCTOR TESTER

An equivalent IC (chip) has come on the market for 10 cents and it is a

better chip.

Using 220uH, the circuit takes 13mA an illuminates 2 white LEDs very

brightly.

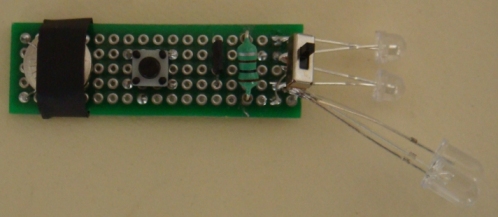

Here is the prototype:

The kit comes with a PCB, all parts: QX5252 Chip, tactile switch, 1.5v

button cell, tinned copper wire for cell and heatshrink for cell-cover,

100uH inductor, very fine wire and 1M to make your own 100uH, 2 machine pins

and length of fine solder, but only 2 LEDs and not the change-over switch.

The prototype has been built on Matrix Board and shows the change-over

switch used to test different LEDs. You will get the Printed Circuit

Board in the kit that has been generated from the layout. This is the

easiest and simplest way to make a PCB and avoid any mistakes.

Here is the waveform:

What is happening?

When you build circuit "B," you will realise the specifications given in the

.pdf for the chip, could be

improved. We have achieved a supply current of 18mA for an equivalent

brightness of 10mA. The chip requires 25mA. So, all the technology in the

world has not surpassed a hand-made circuit.

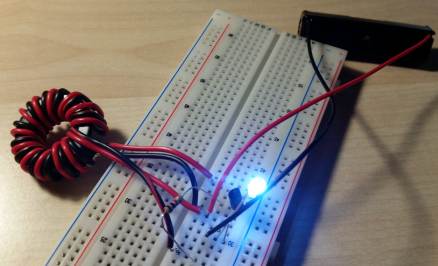

You can clearly see the number of turns on the

toroid.

The circuit is not very efficient because it does

not have a capacitor to improve the efficiency.

BIKE FLASHER - Amazing!

This bike flasher uses a single transistor to flash two white LEDs from a

single cell. And it has no core for the transformer - just AIR!

All Joule Thief circuits you have seen, use a ferrite rod or toroid

(doughnut) core and the turns are wound on the ferrite material. But this

circuit proves the collapsing magnetic flux produces an increased voltage,

even when the core is AIR. The fact is this: When a magnetic filed collapses

quickly, it produces a higher voltage in the opposite direction and in this

case the magnetic field surrounding the coil is sufficient to produce the

energy we need.

Wind 30 turns on 10mm (1/2" dia) pen or screwdriver and then another 30

turns on top. Build the first circuit and connect the wires. You can use 1

or two LEDs. If the circuit does not work, swap the wires going to the base.

Now add the 10u electrolytic and 100k resistor (remove the 1k5). The circuit

will now flash. You must use 2 LEDs for the flashing circuit.

BIKE FLASHER - AMAZING!

THE IMPROVED BIKE FLASHER CIRCUIT

The secret to getting the maximum energy from the coil (to flash the

LEDs) is the maximum amount of air in the centre of the coil. Air cannot

transfer a high magnetic flux so we provide a large area (volume) of low

flux to provide the energy. The larger (20mm) coil reduced the current

from 20mA to 11mA for the same brightness. This could be improved

further but the coil gets too big. The two 30-turn windings must be kept

together because the flux from the main winding must cut the feedback

winding to turn ON the transistor HARD.

When the transistor starts to turn on via the 100k, it creates magnetic

flux in the main winding that cuts the feedback winding and a positive

voltage comes out the end connected to the base and a negative voltage

comes out the end connected to the 100k and 10u. This turns the

transistor ON more and it continues to turn ON until fully turned ON. At

this point the magnetic flux is not expanding and the voltage does not

appear in the feedback winding.

During this time the 10u has charged and the voltage on the negative

lead has dropped to a lower voltage than before. This effectively turns

off the transistor and the current in the main winding ceases abruptly.

The magnetic flux collapses and produces a voltage in the opposite

direction that is higher than the supply and this is why the two LEDs

illuminate. This also puts a voltage through the feedback winding that

keeps the transistor OFF. When the magnetic flux has collapsed, the

voltage on the negative lead of the 10u is so low that the transistor

does not turn on. The 100k discharges the 10u and the voltage on the

base rises to start the next cycle.

You can see the 100k and 1k5 resistors and all the other parts in a

"birds nest" to allow easy experimenting.

This is the first circuit you should build to flash a white LED from a

single cell.

It covers many features and shows how the efficiency of a LED increases

when it is pulsed very briefly with a high current.

The two coils form a TRANSFORMER and show how a collapsing magnetic

filed produces a high voltage (we use 6v of this high voltage).

The 10u and 100k form a delay circuit to produce the flashing effect.

You can now go to all the other Joule Thief circuits and see how they

"missed the boat" by not experimenting fully to simply their circuits.

That's why a "birds nest" arrangement is essential to encourage

experimenting.

Note: Changing the turns to 40t for the main winding and 20t

for the feedback (keeping the turns

tightly wound together by winding wire around them) reduced the current

to 8-9mA.

The inductance of this transformer is quite critical and the voltage

across the LEDs must be over 6v for the circuit to work. It will not

work with one or two LEDs.

The circuits we have presented above use a

single transistor and a transformer to provide feedback. This feedback is a

form of REGENERATION to turn the transistor on HARDER and HARDER to

produce the maximum efficiency.

An oscillator can be produced with two transistors and an inductor, but

there are some design-features that need to be applied to produce an

efficient circuit.

The first circuit is a POOR DESIGN.

Base-current is effectively wasted current or "wasted energy" and

should be kept

to a minimum.

The circuit consumes 10mA and the LED will see less

than 4mA.

By reducing the 10k base bias resistor to 470R the circuit-current increases

to 25mA but the LED is still not at full brightness.

Secondly, the base-current is shorted to the 0v rail via the first

transistor and is completely wasted during part of the cycle.

But the main problem with the circuit is the fact that the driver transistor

is not driven into full conduction at any part of the cycle and the circuit

has very little efficiency.

To solve this problem, the two transistors are connects so the "turning-ON"

is provided by a transistor and it effectively reduces in resistance to a

small value to turn ON the driver transistor.

Theoretically a current-limiting resistor should be added in the base of the

driver transistor (about 47R) but this made no difference to the current

taken by the circuit.

The 1n charges a little more and the current through the base lead reduces

slightly. This action turns OFF the first transistor slightly and the driver

transistor is turned OFF a slight amount.

The voltage on the 1n rises and very soon both transistors are fully turned

OFF.

The magnetic flux in the core of the 1mH inductor collapses and produces a

voltage in the opposite direction.

This voltage is added to the 1.5v rail voltage and the final voltage is high

enough to illuminate the white LED.

This keeps both transistors OFF and when all the magnetic flux has been

converted to energy to illuminate the LED, the voltage on the collector

drops. This lowers the top plate of the capacitor and since the capacitor is

slightly charged, the bottom plate drops to a voltage less than rail

voltage. This action turns ON the first transistor to start the next cycle.

It can be made by winding 50 turns of 0.1mm enamelled wire on a 1.6mm diam

ferrite slug.

I have described the pro's and con's of this chip in another article "Circuit

Tricks" and you should read it and work out what

they really mean.

Kit of components $3.00 plus $4.00 postage

Here is the circuit for QX5252F:

Using 100uH the circuit takes 30mA and the LEDs are really the same

brightness.

Using 33uH the circuit takes 80mA and the LEDs are just about the same

brightness.

Obviously the 220uH creates the most efficient circuit.

Email

Colin Mitchell for details on buying

the kit.

The inductor has been fitted via machine pins and it can be removed and

different inductors fitted to see the results. A machine pin is hollow and

allows to poke the ends of a conductor into the pin and it will make

contact.

The current taken by the circuit changes according to the inductance and

this will enable you to compare inductors and even find the value of an

unknown inductor.

You need to use one, two or three known inductors and make a table of the

inductance and current taken by the circuit.

The current may or may not be linear but we measured inductors from 33uH

1,000uH and recorded currents from 80mA to 2.5mA.

This enabled us to measure unmarked coils.

One more feature of this project is to wind your own inductor and see if

it is effective as the 100uH supplied in the kit.

The kit comes with fine wire and a 1M resistor.

Wind 250 turns on the resistor very carefully and as you come to the end of

the winding, you can criss-cross the wire over the other turns to keep them in

place.

Leave at least 4cm of wire at the beginning and end.

Now heat the wire very close to the body of the resistor with a hot clean soldering iron that has been fully

tinned. The wire will get tinned very close to where it comes from the

winding. Now wind 5 turns around the wire coming from the resistor and

solder it in place. Break off the wire.

Do the same with the other end.

Fit your home-made inductor and the LED should be as bright as the 100uH.

Measure the current across the switch. It should be about 32mA.

The voltage is being converted from 1.5v to 3.5v and each LED will get

slightly less than 6mA by the time you take the efficiency of the circuit

into account.

The first part of the cycle shows the inductor being pulled down to the 0v

rail.

This means the 1.5v for the battery is directly across the inductor and

current starts to flow in the winding.

This produces magnetic flux (called EXPANDING FLUX) that cuts all the turns and produces a voltage

in the turns that is opposite to the incoming voltage.

This means the effective voltage entering the inductor is very small and

thus a small current flows. However enough current flows and enough time is

allowed so the inductor produces magnetic flux.

This is shown in diagrams A and B.

The circuit then immediately turns OFF and the magnetic flux collapses very

quickly.

This is shown in diagram C. This voltage is actually in the opposite

direction to the original voltage and this is one of the most important

things to understand.

The voltage produced by the inductor will be very high (possibly 10v or

more) (and is added to the voltage of the battery. But as soon as the voltage reaches 3.2v, the white LED starts to turn

ON and produce illumination.

The magnetic flux keeps collapsing and supplying energy to the LED for about 2uS

and when the voltage falls to less than 3v, the LED turns OFF.

The QX5252 IC turns ON again and pulls the inductor to the 0v rail to start

the next cycle. The IC operates at about 130kHz and if the inductor has

not lost all its magnetic flux, it will add to the flux on the next cycle.

You can see the inductor only has to produce about 1.7v as the voltage is

"produced" on top of the 1.5v from the battery. The circuit will work down

to about 0.9v

Understanding and interpreting a waveform is very important because the LED

is only turned ON for a very small portion of the time but it is turned ON

very brightly.

Our eyes detect this brightness and hold this brightness while the LED is

completely turned OFF during the rest of the cycle. This effect is called

PERSISTENCE OF VISION.

This is why a very small current will produce high brightness and create a

highly effective circuit.

That's how the circuit got its name: Joule Thief. It appears to get

energy from nowhere. But we know a LED can operate in pulse-mode and product

a very high brightness while consuming a small OVERALL current.

This project will teach you 3 things:

The number of turns to create 100uH inductor, testing different inductors,

testing different LEDs and determining the value of inductance by measuring

the current.

oooooooooooooooooo000000000000000000000000000oooooooooooooooooo

The advantage of our design is the ready availability of components and you

can change them to suit your own application.

If you want to increase the brightness, the 2k7 can be reduced to 1k5.

If you want to drive 2 LEDs, they can be added in series:

Adding a 100u across the battery will increase the current by 4mA and the

brightness will increase slightly.

When 2 LEDs are placed in series, the current drops from 28mA to 23mA and

the brightness from each LED is slightly less. This circuit is operating at

about the maximum capability of the transformer. The actual limiting factor

is the size of the "core." It can only "hold" a certain amount of magnetic

flux and return it to the windings during the collapsing part of the cycle.

A larger core will allow three or more LEDs to be illuminated.

The "high efficiency" of this circuit is due to the "pulsing of the LED." When a

LED is pulsed with a high current for a short period of time, the brightness

is equivalent to a lower, steady, current. That's why a current of 23mA from

the battery will illuminate 2 LEDs with an equivalent brightness of about

8mA of steady current. It is very difficult to compare the brightness of one

LED against another and

these results are the best you can make by visual inspection. We are

not driving the LEDs to their maximum but the output is very impressive.

THE TRANSFORMER

The secret of this circuit is the transformer.

We normally think of a transformer as a device with an input and output, with the

voltage on the input and output being connected by a term called

"turns ratio."

If the output has more turns than the input, the output voltage will be higher.

This is called a step-up transformer. If the output has less turns than the

input, the output voltage will be lower.

This applies to "normal" transformers where the voltage is rising and falling

at a regular rate, commonly called a "sinewave."

But the transformer in this circuit is different.

The voltage applied to it is not rising and falling smoothly, and thus it does

not work in normal "transformer mode."

The voltage is being applied and then turned off. When the voltage is

applied, the primary winding (the 60 turn winding) produces magnetic flux.

When the voltage is turned off, the magnetic flux collapses and produces a

VERY HIGH voltage (in the REVERSE DIRECTION), in all the windings.

Our transformer is really a coil in flyback mode with a feedback

winding.

The feedback winding delivers a voltage to the transistor to turn it on HARDER.

If the winding is connected around the wrong way, the circuit will not work.

The other important factor about the transformer is the core material. There

are many different types of ferrite. Ferrite is a type of iron which is

powdered very finely so that the magnetic lines that pass through the

particles do not create eddy-currents. These eddy currents absorb the

magnetic flux. The material we have used is F29 and this is suitable for

high frequency applications.

The circuit also employs a term called RE-GENERATION. This is the effect

where a circuit is turned on slightly by a component (the 2k7 base resistor

in this example) and then the transistor

turns itself on more and more until it is fully turned on. The feedback winding is configured so that the

voltage it produces (actually the current it produces) is fed into the base

to turn the transistor on.

Thus the feedback winding is very clever. It produces energy and is delivered in a particular direction

- in other words it can be a positive or negative energy. In this case

it produces positive energy, to turn the transistor on harder.

This is called POSITIVE FEEDBACK as it turns the transistor

ON during the active part of the cycle.

Now we come to the MAIN, PRIMARY or FLYBACK winding.

This winding produces a high voltage during part of the cycle (the FLYBACK

part of the cycle) and this is passed to the LED.

If the LED is removed, the transformer produces a high voltage with a low

current, but when the LED is inserted, an amazing thing happens. The energy

from the transformer is converted to a lower voltage with a higher current.

What actually happens is the LED absorbs the energy and turns it to light as

soon as the voltage rises to 3.6v.

We could achieve the achieve the same low-voltage, high current requirement, with less

turns, but the number of turns has actually been determined so the core does

not saturate.

The voltage for the LED is produced when the transistor is

switched off and the magnetic flux in the ferrite core collapses.

The speed of the collapse produces a very high voltage in the

OPPOSITE DIRECTION and that's why a positive voltage emerges from the end

connected to the LED. These two facts are important to remember.

The other important fact is called "transformer action." This is the action of

magnetic flux.

When a voltage is applied to a winding of a transformer or a coil of wire, a

current will flow and this will produce magnetic flux. If another winding is

present, the magnetic flux will cut the turns of this extra coil and produce a

voltage in it.

However, there is a very important point to remember. The magnetic flux can

be: EXPANDING, STATIONARY or CONTRACTING.

When the magnetic flux is expanding, a voltage will appear in the second

winding mentioned above.

When the magnetic flux is stationary, NO VOLTAGE will appear in the second

winding.

When the magnetic flux is contracting a voltage will appear in the second winding with

REVERSE POLARITY.

The size (the amplitude or "value") of the reverse voltage will depend on the

speed of the collapsing magnetic flux. If the flux collapses quickly, the

amplitude will be very high.

That's how the transistor turns itself on and on until it is fully turned

on. At this point the current flowing through the circuit is a maximum but

the flux is not expanding so the base of the transistor does not see the

high "turn-on" energy and thus the transistor suddenly turns off.

The magnetic flux collapses and the transistor sees a reverse voltage on the

base to keep it turned off until the flux is fully collapsed. The current

through the 2k7 enters the base to start the cycle again.

From this you will be able to see how the

transistor and transformer work.

THE FLASHER

Now we come to the problem of flashing a white LED, using a 1.5v supply.

The following circuit performs this task:

The oscillator charges the 100u via the 1N 4148 diode and when the voltage

reaches about 10v, the BC 547 transistors "zeners" (breaks down) and conducts.

Energy

in the 100u is then dumped into the LED to make it illuminate. This causes

the voltage across the 100u to drop and the transistor comes out of

conduction. The oscillator then continues to charge the 100u to repeat the cycle.

The zener voltage of the transistor is not 10v as approx 4v is dropped

across the LED. This conforms with an article on the web that said the

emitter-collector junction is equal to a 6v2 zener.

The 330R charging resistor produces a fast flash and the 1k produces a slow

flash.

The current for the circuit is approx 22mA and any type of LED can be fitted.

Measuring the current-consumption of a circuit is a very difficult thing to

do. When you insert a a meter into the positive line (or negative

line) of a circuit, you introduce extra resistance and the operation of the

circuit will alter. You may think the low resistance of an ammeter will not

affect the performance, but quite often the "ammeter " is really a "milli-amp

meter" and the "shunt resistance" on the 200mA scale can be 4 - 7 ohms. This

is quite considerable when a circuit is operating on 1.5v and drawing 30mA.

This can be a loss of 100mV to 200mV and the current taken by the circuit

will alter considerably.

That's why the best approach is to place a 1 ohm resistor in line with the

positive of the battery and measure the millivolt drop across the resistor.

Each millivolt drop will correspond to 1mA flow and this will change the

circuit conditions as little as possible. The following circuit shows how

this is done:

A 100u electrolytic across the circuit will reduce the impedance of the supply and keep the circuit working as normal as possible.

As a point to note: The White LED Flasher circuit did not start-up on a flat

AAA cell.

Solution: take two flat cells and connect them in series and see how long

the LED will flash. You will be very surprised. The circuit will draw about

30mA and the LED will flash very quickly.

The circuit will continue to work on two very flat cells until the flash

rate drops to one flash per second.

This type of circuit puts a very heavy "strain" or "noise" on the power

supply. In other words it puts a heavy demand on the battery for a short

period of time.

This is not a problem if the only item connected to the battery is the

flasher circuit. But if the battery is also driving a circuit such as an mp3

player or microcontroller, the high-frequency noise may upset the operation

of the electronics.

THE OSCILLATOR TRANSISTOR

The oscillator transistor needs to sink a very high current for a very short

period of time (as mentioned above) and thus it must be a "high-current"

type. A "high-current" type improves the efficiency of the circuit. If the

transistor cannot sink the transformer to the 0v rail, it effectively

becomes a "resistance" in the network. Suppose the supply is 1500mV (1.5v

, 1v5) and the transistor can sink to 500mV, 30% of the voltage is dropped

across the transistor and thus the circuit is using only 66% of the incoming

energy. If the transistor can only sink to 0.75v, the circuit is using 50%

of the incoming energy.

Some transistors can sink to 0.3v and thus the circuit is more efficient.

STABILITY

Now we come to the stability of the circuit. The circuit is very unstable

and very unreliable. Touching the components with a finger changes the

frequency of the flash-rate and connecting CRO to the collector of the

oscillator transistor inhibits the flashing. The oscillator keeps working

but the zener transistor fails to operate.

This circuit is totally unsuitable for a commercial design and it reminds me

of some of the original transistor flasher circuits. They required precise

values of resistance and did not work when the supply voltage dropped.

Fortunately someone came up with the flip-flop flasher and changed

everything. It is totally reliable and operates under all sorts of

conditions.

Now we come to the design of a higher output circuit, to satisfy those who

want to use a larger cell and drive 2 or 3 LEDs to maximum brightness.

HIGHER OUTPUT

To drive more LEDs, a higher output is needed. We have already mentioned,

the limiting factor with the circuits above is the transformer. To achieve a

higher output, the size needs to be increased. This is quite easily done by

getting a larger core. It is the core that determines the amount of flux

that can be stored. When turns are wound on a core, the result is called an

inductor and when a second winding is added, the result is called a

transformer.

Most of the inductors and transformers we use in the circuits in this

article have an open magnetic circuit. This means the flux escapes out one

end of the core and in general the result is not very efficient. But it has

proved to be satisfactory.

An improved core is called a "pot core" and consists of two halves as shown

in the diagram below:

The magnetic lines go around the

"magnetic circuit" as shown in the diagram above and pass through an air

gap. The air gap is to compensate for the DC across the coil (transformer).

If the air gap is closed up, the inductor will saturate before the circuit

is fully conducting and this may make the inductor less effective. All this

theory is very complex and you really have to try the component to see the

effect.

The bobbin is re-wound with 35 turns of 0.5mm wire for the primary and 20

turns for the feedback winding. The two pins connect to the primary and the

20 turn-winding is wound on top, with flying leads. The gauge of the wire is

chosen so that the windings completely fill the bobbin. The feedback winding

can be a thinner gauge, without any detriment to the operation of the

circuit. By the appearance, you could expect up to 5-10 times more output

from the bobbin.

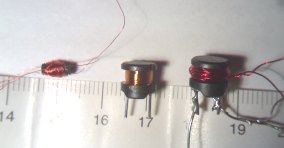

Our circuits use a simple "in line" inductor as shown above or a "bobbin" as

shown below in the third item. The photo below shows the "slug" transformer used in circuits A, B,

and C and the "bobbin" transformer used in circuit D. The size of each

transformer gives some idea of the relative output. The centre inductor is a 10mH

choke. This is unwound to get the bobbin for the transformer.

But with a higher output, you need to provide some form of energy-limiting

circuit to prevent damaging the LED.

The following circuit provides current limiting so that the LED will produce

maximum brightness for the voltage range 1.5v to 0.9v.

This gives a choice to suit a variety of torches. The smallest

penlight torch will only have enough room to drive a single LED while the larger "C" and

"D" cell torches will drive two or three LEDs.

There are some slight differences between each of the circuits and you need to

read the article if you want to deviate from any of the layouts we have given.

For instance, the 2SC 3279 transistor is capable of sinking 2 amps and this

makes it a better driver for circuit-2 but its collector-emitter voltage is

only 10v and it may zener in circuit 3, where the voltage is very near this

value.

Circuit-1 drives one LED from a single cell

Circuit-2 drives two LEDs from

a single cell

CURRENT REGULATION

The circuit includes a feature called "current regulation." You can

also call the feature "voltage regulation" as both have the same effect of

controlling the brightness of the LED.

It can also be called a "constant brightness" arrangement.

It's a feedback arrangement consisting of a BC 547 connected to the base of the main transistor.

When the voltage across the "detector resistor" rises above 0.7v, the BC 547

turns ON and prevents the main transistor operating.

This allows the LED to produce a constant brightness over a wide supply voltage.

The circuit will theoretically work to 0.8v.

Do not remove the current regulating transistor as the circuit will over-drive

the LED when the supply is 1.5v. The excess current will instantly destroy the

LEDs.

The actual operation of the circuit can be explained in a little more detail.

When the circuit is turned on, the oscillator transistor produces a high

voltage from the inductor and this is rectified by a diode to charge a 100u

electrolytic.

When the voltage rises to over the total characteristic voltage of the LED or

LEDs, they turn on and current

flows though the 39R "detector resistor."

The voltage across the 100u will continue to rise and since the characteristic

voltage of the LEDs has been reached, any further voltage rise will appear

across the resistor. As soon as this voltage reaches 0.7v, the feedback

transistor begins to turn on. The feedback transistor acts like a variable

resistor as shown in the diagram below and some of the current from the

feedback winding is passed to the 0v rail, through the transistor.

The oscillator transistor sees a reduced "turn-on" effect and the output of the

stage is reduced.

In this way the brightness of the LEDs can be kept constant throughout the life

of the battery.

Caution: Do not allow more than 25mA to flow though

a white LED (unless it is being pulsed) as it will be instantly DESTROYED. Other

LEDs (such as low-brightness red LEDs) are much more tolerant - but white LEDs

are easily damaged.

CIRCUIT SIMULATION

The output of the transformer (on no-load) will be

more than 200v and thus the circuit must not be operated on no-load as the voltage may

damage the transistor.

In the CRO diagram above, the pulses (or spikes) occupy about 10% of the total

time. Gain: Vbe Vce NPN 140 to 10v 2amp NPN

60 0.7v

NPN 0.7v

The next circuit has some interesting features - the two 1N4148 diodes and the

two 1 watt LEDs in series.

There are lots of JOULE THIEF circuits on the web and many photos and diagrams

showing how the components are connected.

Here are a few circuits from the web:

2 SEPARATE INDUCTORS

2 INDUCTOR CIRCUIT

This circuit is impossible to describe via "logic" and so it was

necessary to put a dual trace CRO on different connections to see what was

happening.

The next circuit works amazingly well.

ANOTHER AMAZING CIRCUIT

The circuit is actually being "pulled back" when a fresh cell is connected, by

the action of the feedback transistor. As the voltage from the cell reduces,

the oscillator circuit will not be able to produce a high output and the action

of the feedback section will not be needed. Eventually the voltage of the

cell will be so low that the LED will start to dim. This is the end of the life

of the cell.

A number of circuits similar to this project have been presented on the

internet. One circuit had twice the number of components and used 4

transistors.

The art of designing a circuit is to make it as simple as possible, while

providing all the needed features.

It is pointless making a circuit complex, as it simply adds to the cost and

makes fault-finding more difficult.

But a note near one of the circuits was really annoying. It said the circuit

"had not

been tested, only a simulation was run." While these simulation programs work in

a number of applications, they certainly cannot take into account the

characteristics of an inductor. This is one item that no-one can predict. It's

performance depends on so many variables.

If you think you can design a circuit

such as this on a simulator, and it will work, you are kidding yourself.

Electronics is not that simple.

Transistors exhibit different characteristics according to the current flowing

though them and

a circuit such as ours requires the main transistor to pass a very high current

for a short period of time.

Fortunately, Japanese transistors are capable of passing a high current while

some Philips transistors will fail to pass the test. The gain of a transistor

under these stressful conditions cannot be determined from a data-sheet.

Circuits should never be presented in an article unless they have been tried and tested.

A simulation program cannot possibly take into account the effectiveness of an

inductor in any particular situation, even though the inductance is known.

There are hundreds of ways to produce a 10uH inductor, or any inductor for that

matter.

It can be air-cored or ferrite cored. The windings can be thick or thin wire. The

core can be made of several different materials. On top of this it will depend

on the frequency of the circuit.

The

output voltage of an inductor that has been specially designed for a particular circuit can be

100 times higher than an incorrectly designed item. That's why it takes a

considerable amount of "trial-and-error" to produce an ideal inductor or

transformer.

The output voltage has a lot to do with the "Q-factor" or quality factor and

this is a value that is associated with the way the inductor or transformer has been designed.

The "Q value" is basically the ratio of the supply voltage

compared to the output voltage.

No simulation program can "guess" the value of "Q" and since the

operation of the circuit is entirely dependent on this value, it has

to be constructed.

I would not even attempt to put this type of circuit on a simulator.

DESIGNING AN INDUCTOR

There are many ways to go about designing an inductor or transformer.

You can sit down and study the theory of inductance, the effectiveness of

ferrite material at different frequencies, the use of different

wire gauges and the associated inductance formulae.

If you think you will be able to produce an inductor for this circuit entirely

from theory, (with the first prototype working perfectly), you are kidding

yourself.

There are a number of parameters you cannot specify in the formulae.

Even if you did come up with an answer, no electronics-designer would be satisfied with the first

result. He would need to see the prototype and add

or remove turns to see the effect. He would use thicker or thinner wire

and note the effect. He would carry out all sorts of experimentation, including monitoring the battery current while noting the current though

the LEDs to work out the efficiency of the circuit.

It could take 50 or more prototypes to arrive at the best design.

So, where do you start when designing a transformer or inductor?

No-one really knows where to start.

It all comes from trial-and-error and guessing a starting-point.

The easiest way is to copy an existing design.

But if you don't have something to copy, you can begin with say 10 turns.

Note the output voltage and current

taken by the circuit.

Increase the winding to 20 turns. Again note all details.

From the figures you can work out if you are going in the right direction.

Continue collecting data with both additional turns

and reduced turns as, sometimes, an unusual feature suddenly

arises.

Keep working until you are satisfied with the results.

Even if you have studied inductor theory, you will still have to carry out the

practical side of things.

Nothing takes the place of actually "doing-it."

DESIGNING OUR

TRANSFORMER

In our 3 circuits, there are many different combinations of windings that will

work.

The reason is the circuit is non-critical.

You have to understand the operation of an inductor in an entirely different

way to the theoretical model to see how it operates.

This is called a "loose" circuit and a wide range of primary windings will

produce the same result.

For example, a primary winding of 35 turns will produce the same LED brightness as

55 turns and the current from the supply will be the same.

If the LEDs are removed, the circuit will charge the capacitor to more than 45v

and this is above the operating voltage for a 100u/25v electrolytic.

If you remove the LEDs and turn the circuit on, then re-solder the LEDs, they

will be damaged. This is because the electrolytic will have charged to 45v.

Thus it is very difficult to experiment with the circuit to see how the transformer charges the

electrolytic.

You will have to follow our explanation:

HOW DOES THE ELECTROLYTIC CHARGE?

The electrolytic is charged by pulses from the inductor.

In circuit-3 the voltage across the electrolytic is 10v and it is delivering

current to the three LEDs at a constant rate of 17mA.

CRO waveform - output of inductor

The area under the graph (under each spike) is shown in orange and this

represents the energy supplied to the electrolytic.

The inductor is capable of producing a very high spike when in flyback and this

voltage allows a burst of current to pass though the diode and charge the

electrolytic.

When the inductor is operating under no-load, it is capable

of producing a spike of more than 200v, but this voltage is not allowed to be produced when

the load is connected. The voltage-spike is limited to the characteristic

voltage across the LED or LEDs, plus the voltage drop across the diode and

minus the battery voltage. The voltage will be about 9v.

If we are drawing 17mA for 100% of the time, we must deliver 10 times 17mA for

10% of the time to keep the electrolytic charged. Thus a current of about 17 x 10 = 170mA

is needed to pass

through the diode to charge the

electrolytic.

The other feature of the diode is it prevents the voltage on the electrolytic being discharged

to the 0v rail via the transistor when it is turned on.

The frequency at which the circuit operates is determined by the inductance

of the inductor. The cycle start when the power is applied and the transistor

turns on to allow current to flow though the main winding. This produces

magnetic flux in the feedback winding to turn the transistor on harder. This

continues until the transistor is turned on fully and maximum flux is produced.

But the flux is not expanding flux and thus it does not cut the turns of the

feedback winding and the transistor does not get the full turn on current into the

base.

The transistor is turned off and this causes the magnetic flux to collapse.

This flux is in the opposite direction and it produces a reverse voltage in the

feedback winding to keep the transistor fully turned off.

The main winding also produces a voltage in the opposite direction and it

delivers a pulse of energy to the electrolytic via the high-speed diode.

As soon as the magnetic flux is spent, (converted to electrical energy) the

cycle starts again.

The combination of these two operations creates the length of time for one cycle.

In our case the circuit operates at

approx 90kHz.

LED OUTPUT

There is a lot of hype and confusion about the light output of some

super-bright LEDs.

Sometimes there is very little difference when you compare the output of 1cd,

3cd and 6cd (6,000mcd) LEDs, when supplied from wholesalers.

One of the reasons is the difficulty in identifying each LED. They have no

markings and if they are not kept in their correct bag, they can get mixed up!

There are literally dozens of different types.

Secondly, the difference in brightness is due to the angle at which the light-beam

emerges from the LED. This is

due to the lens inside the LED and/or the way the LED is potted, producing a

divergent beam or a narrow beam.

Almost all LEDs have a different illumination intensity, color and spot-size,

depending on the manufacturer, beam angle and quality of the chip producing

each color (efficiency).

Some have a blue appearance in the centre of the spot white light while others have a noticeable green fringe.

This project is an ideal way to test 2 or 3 LEDs at the same time. Since they are

in series, they pass the same current and the intensity control will allow you

to vary the brightness and compare the outputs.

When experimenting, keep a record of the type of LED by paining it with red or

while nail polish. Keep the same reference on the bag from which they came.

This will prevent them getting mixed up.

Type:

Current

Case

2SC3279

600

@0.5A0.75v

![]()

BC337

BC338

@300mA

45v

25v

800mA

![]()

BC547

BC548

BC549

70

@100mA

45v

30v

30v

100mA

![]()

CONSTRUCTION

Firstly you need to decide on the type of housing you want to

use. This will determine the circuit you will use, the number of LEDs and the shape of the

PC board.

It's best to get a kit of components as the core for the inductor is supplied

with winding wire and these are normally difficult items to get.

If you want to use the project for experimentation, circuit-3 has an adjustable

brightness control.

The only extra components you will need are red LEDs to take the place of the

white LEDs, when you are setting up the circuit.

IF IT DOESN'T WORK

Things like the orientation of the transistor, diode and LED need to be checked

but the general reason for the project not working is the connection of the transformer. Simply reverse

one of the windings.

It does not matter which way the windings are wound on the ferrite core. By

simply reversing one of the windings, the transformer will work. Do no reverse

BOTH windings as this will not solve the problem.

EXPERIMENTING

Before experimenting with any of the circuits, there are a number of things

you must be aware of.

The inductor is capable of producing a very high voltage when no load is

connected and this can cause damage to the oscillator transistor, the

electrolytic and/or the LEDs.

We have already mentioned some of the ways the components can be damaged and

the most critical component is a white LED. It will not tolerate excess

current, even for a fraction of a second. Ordinary red LEDs are very tolerant

and this gives you a false sense of robustness.

The circuit is capable of charging the electrolytic to more than 45v and if a

white

LED is connected when the electrolytic is fully charged, it will illuminate

very brightly and die.

The situation does not occur when the circuit is operated normally and this

means experimenting with the circuit is risky if you don't know what you are

doing.

One solution is to use 2 red LEDs to take the place of each white LED.

You can take all current, voltage and efficiency measurements with the red LEDs

and when the circuit is operating as required, the LEDs can be replaced

with a white LED.

Don't let the sensitive nature of a white LED deter you from experimenting -

simply substitute them.

This project has been specially designed for experimenting. The main reason for

using a hand-made inductor is to allow different arrangements to be tried.

One point you will have to remember:

The energy from an inductor in flyback mode depends on the amount of ferrite in

the core. The core supplied in the kit can only supply enough energy to fully

illuminate 2 white LEDs.

When 3 LEDs are used, the maximum current it can supply is about 15mA.

FEEDBACK

We have just about covered everything, but a few experimenters have provided

some circuits that should be included.

All Joule Thief circuits need a feedback arrangement to keep the

oscillator producing a waveform.

The simplest is to have an additional winding that provides this waveform

(an increasing voltage) that turns the transistor ON more and more until the

transformer is saturated and cannot supply energy via the winding. At this

point the circuit IMMEDIATELY stops increasing and starts to collapse. The

voltage (energy) in (from) the winding is reversed and turns the transistor

OFF COMPLETELY to assist in the circuit collapsing.

In place of the feedback winding, a transistor and a few components can be

used. It basically does the same thing and the result(s) are the same as it

is easier to use a 2-wire inductor when building products for mass

distribution. 2-leaded inductors are plentiful and cheap.

We are now going to look at some of these circuits and see how to drive the

more-powerful 1-watt LEDs.

All the above Joule Thief circuits consume about 20 to 50 mA to

illuminate 5mm white LEDs.

The next circuits consume over 100mA and are classified as HIGH POWER

circuits.

When you are designing HIGH POWER circuits you are more likely to damage a

transistor from over-heating and you have to be prepared for failure.

The first fact to remember is this: The transistor in all Joule Thief

circuits is turned ON for about 50% of the time and then the collapsing

magnetic field produces energy to illuminate the LED for about 50% of the

time.

This means the peak current is about twice (or more) the average current

supplied to the LED (the current you will measure via a multimeter).

These are only approximate figures to give an idea of what is happening. A 1

watt LED has a characteristic voltage across it of about 3.3v to 3.6v

and this means the current will be 330mA.

If we are pulsing the LED, this current will increase to more than 500mA for

very short pulses and this current must be handled by the transistor.

When a transistor has to supply a high current, the collector-emitter

voltage increases and it may be 0.5v at low current but increase to 3v when

the current is increased.

That's why the "hidden" operation of the circuit is completely different to

what you are expecting. By "hidden" we mean the short pulses of high

current.

In fact you can't measure the current in the normal way because the

resistance of the shunt in a multimeter will lower the current considerably

and produce a false reading.

In addition, the high frequency of the circuit will produce a completely

inaccurate reading.

All current readings must be taken across a 1 ohm resistor in the supply and

using the millivolt scale to produce a reading of 1mA for each 1mV on the

scale.

These circuits have been provided for your experimentation. The

effectiveness of their performance will depend on the driver transistor and

the inductor.

Some transistors work much better than others and some inductors produce

much better outputs than others.

In the following circuit, Samuel Budiyanto

budiyantosamuel90@gmail.com

used a 1N5819 Schottky diode, in place of the UF4004 and a 1.0mH coil from

a disposable CFL, lamp (150 turns, 0.25mm on 5mm ferrite rod).

The current was 180mA from 13.7v and the output was 360mA @ 5v.

This is about 80% efficient. The 1k was increased to 10k.

Samuel Budiyanto

budiyantosamuel90@gmail.com

suggested using 2SD882 in place of BD139 and decrease 47n to 10n.

Experiment with it yourself.

The operation of the circuit is very complex and takes a lot of description

to fully explain it.

Even though this project uses only a few components, you should build a few

of the different design and see how they compare.

Don't use more than one cell or the LED will illuminate when the circuit is

not working !!

All the circuits described above use and inductor with feedback winding and

it is very easy to show the output of the feedback is moving in the opposite

direction to the output of the main winding and we call this "out-of-phase"

and it is 180° out of phase.

This is the signal (or pulse) that is needed to turn on the transistor

harder and harder to create the first part of the cycle.

It is the magnetic flux from the main winding that passes through the core

and produces the voltage in the feedback winding.

But in the following circuit the two coils are surface mount inductors and

they are 10cm apart and can be connected either way to the circuit and the

LED illuminates.

Thus there is no magnetic interaction between the two components.

But here's the secret. The inductors are about 100microHenry to

470microHenry and these are what we call the "high-speed" components in the

circuit.

The 1n2 capacitor is what we call the "slow component." Unless you

take on this way of thinking, you will not be able to see how the circuit

works.

The circuit starts by charging the 1n2. The resistance of the 470uH + 470uH

is very small and the capacitor charges quickly.

As soon as it gets to 0.6v, the transistor start to turn ON. But the

transistor has to turn on fairly hard to reduce the voltage at the join of

the two inductors and thus the voltage on the capacitor has to rise higher

to create a current through the 6k8 resistor.

The first thing to point out is this:

The two inductors are not near each other and do not produce or have any

magnetic influence between them.

Thus there is no feedback in the normal sense of a transformer or feedback

winding.

Secondly, the circuit is very reliable at self-starting but the values of

inductance and capacitance need to be in the range shown. The inductors used

in the experiments ranged from 100uH to 330uH and the capacitor from 1n to

3n3.

All the circuits described to date in the "Joule Thief" category worked on

the principle of FLYBACK, in which the transistor is turned ON very hard and

immediately turned off so that the magnetic flux in the inductor or

transformer produces a very high voltage.

This circuit works differently.

The turning ON and OFF of the transistor is much smoother and the voltage

across the capacitor is a perfect sinewave.

But the mystery is this: how is the transistor turned ON more and more to

get to the saturated state.

All we can say is this: The circuit starts to turn ON by charging the 1n

capacitor and current flows through the two inductors.

This puts energy into each inductor and when the transistor starts to turn

ON, the voltage at the join of the two inductors decreases.

You can see this on the oscilloscope and when the transistor turns ON more,

the voltage out of the end of the second inductor charges the 1n with a

sinewave to 3v. This is sufficient to put current through the base resistor

to fully turn ON the transistor. The charge on the capacitor gradually flows

into the transistor and it decreases. When it drops to 0.6v, the transistor

turns OFF and the energy in the first inductor produces a high voltage spike

to illuminate the LED.

At the same time current flows through the second inductor to charge the

capacitor to repeat the cycle.

The first question you ask is: How can the second inductor produce an output

voltage of 3v when one lead is being taken to 0v.

The answer: The current through the inductor at the beginning of the cycle

is fairly high and this produces a lot of magnetic flux. When the left

lead is taken to 0v, the magnetic flux collapses and if it collapses fairly

quickly, the inductor produces a high voltage in the opposite direction to

the original voltage. That's what happens in this case. The voltage may be

double but the output current will be half. Or alternatively, the current

multiplied by the original time for the effective current to flow, will be

equal to the output current and the duration it will flow. The output

current will depend on the voltage produced when the flux collapses and the

resistance of the circuit it is being delivered to.

The only simple way to describe this is to say the energy absorbed by the

inductor in the first place will be equal to the energy it delivers (minus

losses).

What we are talking about is the watt-second. In other words, volts x amps

for a period of time.

Obviously, in this case it is milliamps and less than 1 volt for a few micro

or milliseconds.

But it is the fundaments we need to get across.

The value of 1 volt x 1 amp for 1 second is the joule, and someone came up

with the clever name JOULE THIEF, to describe these circuits.

There is no creation of energy from "no-where " in these circuits.

It's just that energy can be converted from a: "dribble over a long period

of time" to a "short, sharp, big bang." - like pulling back the string of a

bow or hammering with a sledge hammer.

An inductor can create a conversion.

You can pass a current through an inductor from a 1v supply for say 1 second

and when the voltage is turned off, the inductor will produce an output

voltage of say 2v for 1 second but the output current will be half. Or the

output can be 4v for 25% of the original current. You can get all sorts of

results but the combination of the voltage, current and time cannot be

greater than the original combination.

This is simply called the CONSERVATION OF ENERGY.

ENERGY IN = ENERGY OUT (minus losses).

That's why this circuit appears to create MAGIC. But it simply converts one

of the parameters to a higher value and one or more of the other parameters

is reduced in value.

Obviously designed by someone "fooling around" as it does not conform to

convention.

This circuit has never appeared in any text book, website or forum. It

appears to be fake. But when you construct it, the results are

amazing. The circuit draws 8mA when the base resistor is 68 ohms and the

other component used in the test circuit was 3n3 for the capacitor.

It's not simple in operation and needs to be explained carefully to show how

the high voltage is generated.

The capacitor charged very quickly via the resistor and when the base of the

transistor sees 0.6v, it turns ON.

The resistor is a very low value and it will have the ability to fully turn

the transistor ON.

This action takes the collector to about 0.3v above the 0v rail.

The base is at 0.7v and the voltage difference puts current through the

inductor to produce magnetic flux. And as the transistor turns ON, the

current increases. This produces EXPANDING magnetic flux.

Eventually the transistor turns ON fully and although the current is a

maximum, the flux is called STATIONARY flux and it does not cut all the

other turns of the inductor to produce a back emf (voltage). The inductor

changes its characteristic from a high impedance component to become a

resistor of a few ohms and it discharges the capacitor and the base voltage

drops a very small amount. This reduced the current flowing

through the inductor and thus the current cannot maintain the large amount

of magnetic flux. This causes the strength of the magnetic flux to reduce

and now we call the flux COLLAPSING flux. This creates a reverse voltage in

the winding and the voltage that was higher (or more positive) on the base

is now LESS and the voltage on the base reduces. It only has to reduce by a

small amount and the transistor turns OFF.

The magnetic flux keep collapsing and the collector lead effectively

disappears. The only thing left on the right-hand lead of the inductor is

the LED.

Because the flow of current has ceased, the magnetic flux collapses very

quickly and this produces a very high voltage. The charging voltage

will have been only a few hundred millivolts, but the collapsing voltage can

be as high as 10v to 12v.

But the LED starts to turn ON when the voltage reaches 3.4v and so the

excess voltage is converted into current to illuminate the LED very

brightly.

When all the magnetic flux has been converted, the supply starts to charge

the capacitor via the resistor to start the next cycle. The frequency of

operation of this circuit can be anywhere between 50kHz and 180kHz.

| |

|

![]()

27-10-2017