|

Point Controller |

Talking Electronics has produced a number of Point Motor

Controllers, but this project uses a motor and gearbox to

control the points.

In other words it is a controller-circuit AND a POINT MOTOR - all for

$15.50

The kit contains a miniature motor / gearbox. This is a

miniature SERVO that needs to be modified by removing the

electronics and connecting two leads directly to the motor.

A DPDT push-switch is also included in the kit. This push-push

switch can be substituted for a toggle switch for $1.50 extra.

In other words this project is a controller-circuit AND a POINT MOTOR - all for

$15.50

All you have to do is connected the arm (commonly referred to as

a "horn"), on the output shaft of the servo, to a manual set of points and you can control them

remotely.

Each time the DPDT switch is changed, the voltage to the circuit

reverses and the opposite transistor conducts for a short period

of time while the electrolytics on the base charge. This

activates the motor to change the position of the points.

There is a small leakage through the transistors of about 20mA

at all times and that's why the project cannot be connected to a

battery.

It can be fitted in many different ways.

Laying it on its side will be the best option.

WHAT THIS PROJECT DOES:

The block diagram shows the project uses a Double-Pole

Double-Throw switch to reverses the voltage to a motor contained in a

servo, to change the position of the rails at a "point." The project

also has a timing feature to prevent the motor "jamming" and

burning-out.

The miniature motor and gearbox comes from a servo (commonly

called a servo motor) and all you have to do is remove the PC

board inside the case and connect two leads directly to the

motor.

A Simplified block diagram of the

project

The gearbox delivers a very high torque to the output shaft

and we need to be careful not to supply full voltage to the

motor when it has reached its "limit-of-travel."

That's why the circuit reduces the current to the motor by the

time it reaches the "end-stop."

The transistors are designed to limit the current by the action of

the electrolytic charging via a resistor and slowly reducing

the current into the base.

When the supply is reversed via the switch, the initial current

is high and gradually tapers off when the arm reaches the limit

of its travel. This means the motor has very little torque by

the time it reaches the end and prevents "jamming."

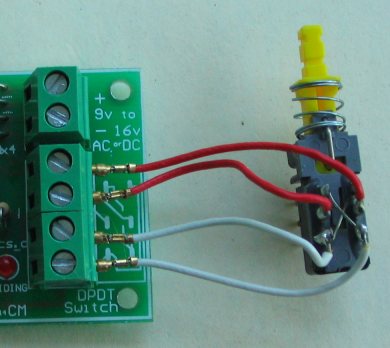

The 4screw terminals on the PC board have been positioned so

each connector aligns with the 4 terminals on a DPDT

switch. Two criss-cross

wires are fitted to the switch to connect the other two terminals. This makes it easy to wire the switch. The kit comes

with a DPDT push-switch that you can change for a toggle switch.

The PC board also contains a red LED and green LED to let you know the

position of the points.

This is a very low-cost project for activating a set of points.

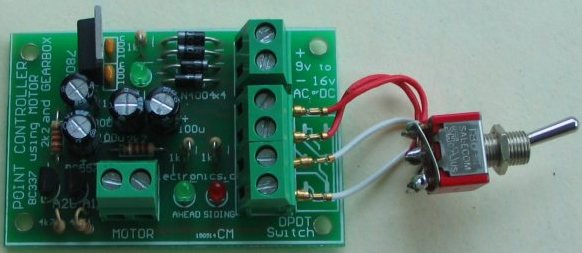

Point Controller project connects to Motor/Gearbox

(modified Servo)

The DPDT toggle switch is $1.50 extra

The Push Switch is provided in the

kit.

CONSTRUCTION

All the parts fit neatly on the PC board.

The transistors, diodes, electrolytics and LEDs are identified above and

the diagram shows how they are fitted to the board.

There is one unusual thing on the board. The AHEAD and SIDING LEDs are

placed in opposite directions. One LED has the cathode lead "down" and

the other has the cathode lead "up," so one LED illuminates when the

voltage is in one-direction and the other LED illuminates when the

voltage is reversed.

The screw terminals allow the board to be easily connected to your power

supply via leads into the 2-connector block. The motor connects to

another 2-screw connector while the DPDT toggle switch connects to the

4-screw block.

MODIFYING THE

SERVO

Only a motor and gearbox are

required for this project. We have used a servo because they are cheap

and compact.

Open up the servo and remove the PC board with electronics. Connect two

leads directly to the motor and re-fit the case. Check the motor on 1.5v

for activation in both directions.

Fit an arm to the output shaft and use the tiny screw provided to hold

the arm in place.

It is now ready for connecting to the track with a push-rod.

CONNECTING THE SERVO to

the TRACK

The arm of the servo produces a certain

amount of THROW.

This is the amount of lineal distance moved by each of the holes in the

arm. If you select a hole near the shaft, the "throw" will be very

small. As you select a hole further from the shaft, the "throw"

increases.

You have to match this distance with the amount of movement needed by

the moveable rails, called "blades." Once you select the required

hole, the unused part of the arm can be removed. This will allow you to

place the servo in a number of positions next to the track, so the arm

can be connected with a push-rod. This can be a small length of

spring-steel from a spring.

The servo has two mounting holes and you can make a small "L-bracket" to

fit it to the base-board. Otherwise it can be glued in pace with clear

silicon sealant. Make sure the action of the servo produces a small

amount of pressure to keep the blades against the fixed rails when it

reaches the end of travel in each direction.

|

Point Controller |

|

3 - 1k 2 - 2k2 2 - 4k7 2 - 100n monoblocks - 0.1spacing 4 - 100u 25v electrolytics 1 - BC337 1 - BC557 1 - 3mm red LEDs 2 - 3mm green LED 4 - 1N4004 diodes 1 - 7805 regulator 4 - 2-Connector terminal blocks

1 - DPDT push-switch |

5-6-2014