|

PIC Fx-1 |

|

|

|

Use this project to

burn your own chips for: PIC DICE XXXX Build Logic Probe/Pulser (slimline) $8.00 kit, to check the operation of the add-on circuits you design. You will also need: - PIC Burner Board. We will not be using the pins at the top of the PCB but burning the chip on the PIC Burner PCB and transferring it to the project. You will learn: - PIC micro programming - Design and build interface stages for input and output devices - Build and use a Logic Probe to test circuit operation - "Burn" (flash) (program) PIC chips using onboard ICSP pins - Build additional projects using PIC micro's - Get $1,000 worth of electronics skill for $50.00 !!! |

"PIC Fx-1" is a DEVELOPMENT PLATFORM - a Prototyping Module.

It's a small board containing an 8-pin microcontroller and a matrix area for experiments.

$12.00

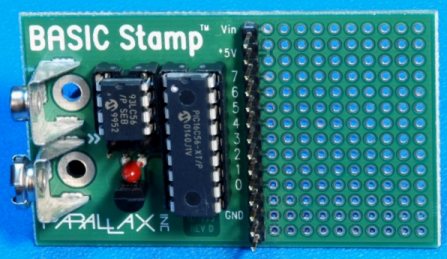

It's very similar to the original BASIC stamp-1, developed in about 1993 to

get beginners into the world of programming.

The experimental section had no supply rails and a very awkward

matrix-layout. A matrix layout needs to be long and thin as that is the

way a circuit extends. There was no on-off switch and you had to

constantly clip the battery to the battery-snap. My BASIC Stamp remained

in pristine condition because it came with no components for

experimenting and "did-nothing" when turned ON. On top of this I very

soon realised the programming had nothing to do with PIC

microcontrollers.

$30.00

The end result is more value for your money with a much-simpler approach

to programming. And your program can be about 4 times larger.

The BASIC Stamp came "empty" and you had to download programs to

see any results. PIC Fx-1 comes with 4 main PROGRAMS for the 3 input switches

and 3 output LEDs.

You can see what can be done with a micro as soon as you assemble the

kit. The second part of this article teaches you how to produce a program by

cutting and pasting sub-routines into a template.

This is how you create a program. You

actually use the instructions needed by the micro (not a

programming language called a "high-level language"). Only 35

instructions are needed for the micro and they are provided in a single-page layout,

for easy access.

You regularly use only about 20 of these and they are in

the "cut-and-paste" code you take from other programs and also

from the LIBRARY OF ROUTINES.

In most cases you go to a project and take the code that performs the

function you require.

You place it in the sub-routine area of the template and CALL it from

the MAIN routine.

Once your program is complete, it is "burnt" or "flashed" into the

memory of the micro (called the program memory section) via a programmer

(called USB Programmer) using the In-Circuit programming pins

at the top of the board.

This will erase the

programs supplied in the chip, so additional chips are recommended if

you want to write your own

programs.

The chip on the board comes fully programmed with the LED Fx-3 program

(with more

than 10 effects), plus 3

extra programs:

Code Lock, Reaction Timer and 4-Alarm Sounds.

The 10 effects on the 3 LEDs include flashing, dimming and random

flickering and you can

produce your own sequence on the LEDs and store it. All these program

use only 65% of the memory. That's how much you can get into a very

small microcontroller. Only one of these program would fit into the

BASIC Stamp due to the micro being filled without routines that are not

needed and you program had to be fitted into an external chip that was

limited to a maximum of about 80 instructions. Our 4 programs require

about 600 instructions.

You cannot compare the two via the number of instructions as

the BASIC Stamp can multiply an instruction to between 2 and

20 PIC instructions. However the BASIC Stamp may take 2 to

4 locations to hold an instruction (and up to 10 locations). So, the BASIC Stamp-1 runs

out of programming capability very quickly and in the past 20 years we have only seen

very small projects using it. That's why they upgraded their range to

much larger PIC chips.

But our aim is not to compare or contrast our concept with any of

the other modules on the market as they are fulfilling a need to get a

simple project up-and-running via a micro.

We are showing HOW to PROGRAM, How the Micro Works and how

1,024 lines of code (instructions) can be used to produce very impressive projects.

Go to P2 for: "learning to write your own programs."

It has a set of experiments to teach PIC

programming - starting with

flashing a LED.

The CIRCUIT

The circuit is very simple. It is

just a micro, 3 LEDs and 3 switches. All the work is done by the micro.

We have added a 5v regulator so the project can be connected

to any voltage from 7v to 15v.

It will work on 6v if the regulator is removed and a diode is placed between

the "in" and "out" pads or on 7v to 15v

DC with the regulator fitted to the board.

This makes it suitable for a 9v battery or the DC supply from a model

railway.

The 5 In-Circuit Programming pins allow you to program the chip

while it is in-circuit.

The matrix section is longer than shown and provides

plenty of space to add components and design your own interface stages

to drive motors, LCD displays, servo's, piezo's etc.

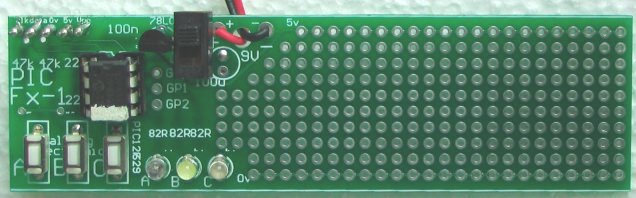

PIC Fx-1 PCB

The Matrix section is 21 holes

x 10 holes

Driving many of the output devices have already been covered in other projects,

so you don't have to "re-invent the wheel." You just copy the

required instructions into your own program.

The top and bottom lands are positive and negative rails

These pins are not used - the project has been updated

and we now use the PIC Burner board and transfer the chip

after it has been burnt

| to USB Programmer | to 9v battery |

This connector-board is not used - We now use the PIC Burner module  |

|

CONSTRUCTION

Build the project on the PC board

provided in the kit. All the components are supplied, including parts

for the experiments.

There are two things to note.

The 100u electrolytic is replaced with a 10u tantalum soldered under the

board. The lands can just be seen at the edges of the component and by

tinning the pads first and using a little fresh solder, the tantalum

will solder very nicely to the pads. The other item to note is the link

to pin-1 of the micro. This track is missing from the board and must

be connected via a short length of fine tinned copper wire (included in

the kit). The 5 programming pins are called "machine pins" and are

soldered directly to the top of each land by adding a little solder to

the land and the hollow end of the pin.

To make soldering these pins in place, insert a pin into the end-pin on

the 5-pin connector and use it to place the pin onto the land you have

just added a small amount of solder to. Heat the pin and it will be

soldered in place. Remove the 5-pin connector and add another pin to it.

Re-connect the 5-pin connector and locate the next pin to the pre-tinned

land. Solder it in place.

Repeat until all 5 pins have been added to the board.

SURFACE-MOUNT COMPONENTS

To make the PC board as small as

possible, we have used surface-mount components. You will need fine tweezers to hold them in place while

one end is soldered.

Always use very fine solder (as supplied in the kit) as you only need very little for each

component and the main reason for adding extra is to take advantage of

the flux to clean the connection. Always solder the SM resistors with the value

showing.

PIC Fx Modification

Turn the PC board over and connect the middle 47k and the end 47k

surface mount resistors to the 22k resistor as shown in the image.

820 on chip = 82 and no zero's

223 = 22 + 000 = 22,000 ohms

4702 = 47 + 0 + 00 = 4700 ohms

THE LEDs

The LEDs supplied in the kit are high-bright 3mm white LEDs that take less than

17mA to achieve full brightness. You can change them for other

colours to suit your own

application. The 82R dropper resistors will have to be increased to 220R

(221 on a chip resistor) for any other colour.

TESTING

LED Fx-3

When you have constructed the project, you can

tests its features:

Turn the project ON and the LEDs will “chase.”

Turn the project OFF and push button A and keep it pressed while you

turn the project ON. Now press button A 3 times and each time the LED

will illuminate. Now stop and wait. The LED will flash 3 times.

Turn the project OFF and push button A and keep it pressed while you

turn the project ON. Now press button B once and wait. The middle LED

will flash.

Now do the same will all sorts of button sequences (up to 15) and see

how the project responds.

Keep the micro and use another micro for your experimenting.

THE PROGRAMS

The 3 programs contained in the chips that comes with the kit of parts

has a single program with sub-routines for the 3 programs.

The micro starts in the Set-Up routine and looks for the press of button

A, B or C to go to the required section of the program.

If NO button is pressed, the micro goes to LED Fx-3 routine.

This allows four separate projects to be included in a single chip. This

concept is very handy for a programmer to be able to get into a program

(after installation) and change data values. The data values are stored

in EEPROM - more on this concept, later.

This program produces a number of flashing

LED effects and can be set so that any of the sequences will show when the

module is first turned on.

It uses about 400 instructions to produce the effects and the EEPROM is

used to store the sequence

produced by the user (sequence 1) - and show it at turn-on.

Here are the instructions:

|

INSTRUCTIONS FOR USE There are 12 sequences. The first sequence can be created by the user. It currently produces a very slow flash-rate as it has not be programmed. The other 11 sequences are pre-programmed. Turn project ON. Allow all the LEDs to flash two times then push the first button (called SwA) and hold it down and the sequence will change to the next sequence. Release the button and allow the sequence to cycle. Push SwA again and the sequence will change. You need to allow each sequence to cycle with the button not-pressed and then push SwA and keep it pressed until a new sequence shows. This is due to the debouncing in the program. TO CREATE YOU OWN SEQUENCE. 1. Press SwA and at the same time, turn project ON. 2. Release SwA and press the switches in any order (up to 15 steps). A step or delay cannot be longer than 2 seconds as the program will "time out." When finished, wait 3 seconds and the sequence will show on the LEDs. 3. Turn project off and on. The new sequence will appear as the first sequence. TO MAKE ANY SEQUENCE THE FIRST SEQUENCE Any of the sequences can be saved as the first sequence, as follows: 1. Turn the project ON and increment the sequences. 2. To save the desired sequence, press SwB. The display will die. 3. Turn project OFF then ON. The desired sequence will show at start-up. 4. To delete this feature, push SwC and at the same time, turn project ON. |

CODE LOCK

THE PIC12F6299

HISTORY

This is a one-time

programmable device with one full port of 8 in-out lines and a half-port

of 4 lines.

program

your own chip or modify the program, the .hex file is available as well

as the assembly file, so you can see how the program has been written

and view the comments for each line of code.

OTHER PROJECTS

The

PIC Fx PROGRAM

PIC Fx-1

14/6/14

This program is contained in the PIC Fx chip.

It is accessed by turning the project OFF.

Now press the first button.

Turn the project ON.

The first LED will flash to indicate the CODE LOCK program is accessed.

To open the "VAULT" you have to press the three buttons in a particular

order.

This project is ideal for a DOOR LOCK.

Normally the code will freeze after 5 attempts, but we have removed this

feature to see if you can "break the code."

The answer to the code is revealed at the bottom of this page.

REACTION TIMER

This program is contained in the PIC Fx chip.

It is accessed by turning the project OFF.

Now press the second button and keep it pressed.

Turn the project ON.

The second LED will flash to indicate the REACTION TIMER program is

accessed.

This program will test your reaction time.

Press the first button and the first LED will come ON.

Keep the button pressed.

The first LED will remain ON an unknown period of time and when it

extinguishes, you must release the first button and press the

third button (with the same finger).

The middle LED will flash to indicate tenths of a second.

4

ALARM SOUNDS

This program is contained in the PIC Fx chip.

It is accessed by turning the project OFF.

Now press the third button and keep it pressed.

Turn the project ON.

The third LED will flash to indicate the 4 ALARM SOUNDS program is

accessed.

Press the first button to access the first sound. Press the button again

for the second, third and fourth sound.

The PIC12F629 is

one of the smallest microcontrollers in the series that has enormous

capability.

The smaller devices are very limited and cost about the same.

The chip has 8 pins.

Two pins are for the 0v and 5v connections. The 5v must not go above

5.5v and can be as low as 3v, but it is best to keep the supply at 5v.

A 100n should be placed next to the chip across the supply rails to make

sure the chip works. The chip likes "tight" power rails and the 100n

does this.

The chip has an inbuilt 4MHz oscillator and this is divided by 4 so it

executes instructions at the rate of one million per second. Each

instruction takes one microsecond.

When an instruction tells the micro to go to another part of the

program, it takes two cycles (2uS) - called Machine Cycles. This is a

skip, goto, call, or return.

The other 6 pins are input/output lines and these can be changed at any

time during the running of the program.

The only thing to remember is pin 4 (General Purpose Input / Output)

gpio,3 is INPUT ONLY. If you try to make it an output, nothing

happens !

You can make any combination of pins "inputs or outputs" and this can be

changed during the running of a program.

The pins have 3-states called TRI-STATE. Any pin can be HIGH or LOW and

when it is configured as an input, it is HIGH IMPEDANCE. In other words

it is not connected to anything.

An output pin can deliver up to 25mA and this is called SOURCING.

This is enough to illuminate a LED and the white LEDs we have provided

in the kit are too bright to look at.

When a

pin is LOW it can sink about 25mA.

That's all you need to know to get started.

Let's go back and see how the microcontroller prototyping

module started.

It started with Parallax producing a small board with a PIC chip and

prototyping area in about 1993. The module cost about $50.00 (with a

very large manual) and used a

PIC16C56.

BASIC Stamp-1 (1993)

However the 4 lines of the half-port are taken up with connections to

the 93LC56 (246 byte EEPROM) to store data and your program instructions and the In-circuit

Programming pins. This leaves the 8-line full-port for experimenting.

The BASIC Stamp-1 has 256 bytes of program storage inside the 93LC56 and this is enough for 80 to 100

lines of PBASIC1 code. The PIC12F629 has this feature INSIDE the chip

and that's why the extra chip is not needed for the PIC Fx-1 module.

None of the code you produce is placed in the normal programming section

of the chip. This area is already taken up by Parallax's set of

sub-routines and these routines are accessed by a code written by you

and stored in the 93LC56 EEPROM.

This is like buying a diary and having it filled with examples of how to

writes stories, essays and poems, and providing 20 pages in a folder,

tacked on the the back of the diary, for

your own work.

All the unused sub-routines should have been left on your computer and

only those needed downloaded into the chip.

But to prevent anyone accessing the sub-routines, it has been contained

within the chip and the CODE PROTECT 'bit" activated so the chip cannot

be read.

This just leaves the 93LC56 EEPROM for you to use. The instructions

written by you are called PBASIC instructions and they take a variable amount of space

in the 93LC56

EEPROM. They vary due to the

complexities of the command and the type of arguments you supply. Generally, each

command takes 2 to 4 bytes of memory space, however, commands like SERIN,

SEROUT, LOOKUP and

LOOKDOWN, which accept a variable length list of arguments, may take

tens of bytes or more.

It is difficult to equate this to lines of ASSEMBLY CODE, when you are

programming the micro via the set of 56 instructions that come with the

chip, as some PBASIC instructions will be equal to 3 lines of assembly code and

others will be equal to more than 20 lines in a sub-routine.

But the main reason I did not use the module, and kept it in pristine

condition for the past 20 years was due to the fact that programming the

chip in BASIC had nothing to do with a PIC MICROCONTROLLER.

Any project developed on the BASIC Stamp-1 could not be transferred to a

PIC chip as a .hex file and this made the project very expensive.

Since the PIC chip we are using costs less than $2.00 and holds a program of 1,023

instructions, it seems only sensible to develop a Prototyping Module

using the smallest PIC chip in the series and show what can be done.

The underlying approach of Talking Electronics is to present simple

projects to get everyone STARTED.

The only way to achieve this is to lay everything out and explain things

in the finest detail.

It's no-good including complex words, involved terms or phrases that

need a Philadelphia lawyer to interpret.

The BASIC Stamp-1 comes "empty," whereas the PIC Fx-1 modules comes

"full."

It has 4 projects already "burnt" into the PROGRAM SPACE and all you have

to do is build the project, connect a battery and turn it ON.

It will immediately come ON with LED Fx-3 program and by pressing

buttons A, B or C before turning the project ON, you will be able to

access the Code Lock, Reaction Timer or 4-Alarm

Sounds.

Once you see how much can be fitted into this tiny chip, you will see

why we started with such a small device. It's the place to start.

PIC Fx-1 module can duplicate almost all the projects designed

for

the Basic Stamp-1 that use up to 6 in-out lines. But compare

the cost: (about $30.00 for the Basic Stamp-1 module plus $18.00 postage to $12.00 for the

PIC Fx-1 Module, plus $6.50 postage from Talking Electronics).

The 4 projects that come with the PIC Fx-1 Module could NOT be

fitted in the Basic Stamp-1 because there are over 500

instructions and the Basic Stamp-1 only has room for about 100.

That's what limits the Basic Stamp-1. Most of the programs

in the Stamp Manual and those submitted by readers have been very simple and equate to less than 300

lines of code in an ASSEMBLY PROGRAM.

There is one advantage of using

assembly.

As you increase the size of a program, you will be able to use some of

the previous sub-routines and this will allow you to do a lot more with

just a few lines of additional code, as you reach the end of memory. All

the programs in the

PIC Fx micro only occupy 664 locations, leaving about 360

locations (lines - instructions - for another program).

When you write a program in assembly, you are aware of the timing for

each of the routines and understand what each line is doing. You are

ACTUALLY programming and not writing an entry into your diary by writing

the words MY DOG and having the book look up the pages of pre-written

text

on the features of MY DOG, to explain what is meant.

No-one has thought of our copy-and-paste technique and that's why they

came up with the Basic Stamp-1 concept.

Not only is our concept simpler, but you don't have to learn any

language, and you get the full capability of the chip.

Overall, our approach will achieve two things.

It will get a new group of beginners into the world of microcontrollers

at very low cost and show how to produce a program to do almost anything

you want.

Once you get into microcontrollers, you will NEVER go back to complex

discrete componentry.

The PIC Fx-1 Module can replace more than 12 individual chips, as proven

by the programs it contains when purchased.

Don't be put-off by the small size. It has 3 inputs and 3 outputs. These

can be changed, but to keep things simple, it is best to keep to

projects having-up to this requirement.

The main idea is to duplicate projects you have seen in publications and

think of your own ideas. You can program the module to carry out these

tasks and cut the prototyping area to make the module as small as

possible.

The PIC12F629 is one of the smallest micros in the range but you will be

surprised how much can be achieved with such a tiny micro.

The program contains sub-routines to produce delays, sequences on the

display and both read and write EEPROM; jobs that require accurate code

- including a special sequence - called a handshaking sequence that

prevents the EEPROM being written due to glitches.

Even a program as simple as this is not easy to put together and to

assist in this area, we have provided a whole raft of support material.

Not only do we provide a number of programs with full documentation but

our approach to programming is simple.

It involves a method of "copy and paste" whereby sub-routines

are taken from previously written code and copied into your program. Any modifications are

made in very small steps so that each can be tested before adding more

code.

This is exactly how we produce a complex project. Each step is written

and tested before adding the next step.

This saves a lot of frustration as it is very easy to add a line

of code that is incorrect and get an unsuspected result.

If you follow our suggestions you will buy a programmer ("burner")

called a PICkit-2 if you are using a laptop. It is the cheapest and best on the market

and comes with

a USB

cable and 2 CD's containing the programs needed to "burn" the chip.

If you are using a desk-top and/or tower with a serial port, you can use

a cheaper programmer called MultiChip Programmer from Talking

Electronics. You

will also need NotePad2 to write your .asm program. This can be

downloaded from Talking Electronics website. You will use

LED_FX.asm or

LED_FX-asm.txt as a template for your

program, plus a 6 pin to 5 pin connector that fits between the burner

and the project. This is also available on Talking Electronics website.

As we said before, this project is for medium-to-advanced programmers as

it is very compact and does not have in-circuit programming pins.

To be able to modify the chip you will need a programming socket and

this can be obtained from one of our other projects that contains the 5

pins for in-circuit programming.

You can then put the chip into the other project to be programmed and

modified and re-fit it into this project for execution.

PROGRAMMING LANGUAGE

There are a number of kits, programs and

courses on the market that claim and suggest they teach PIC Programming.

Most of these modules and courses use a PIC microcontroller as the chip carrying out

the processes, but the actual programming is done by a proprietary

language invented by the designer of the course.

Although these courses are wonderful to get you into "Programming

Microcontrollers" they do not use any of the terms or codes that apply

to the PIC microcontroller family.

All our projects use the 33 instructions that come with the PIC

Microcontroller and these are very easy to learn.

We use the full capability of the micro and our pre-programmed chip is

less than the cost of doing it any other way.

In addition, anything designed via our method can be instantly

transferred to a PIC die and mass produced. And we use all the input

pins and all the memory of the chip. The other approaches

use less than 25% of the capability of the memory and one of the pins is not available.

In fact it would be difficult to reproduce this project via any of the opposition

methods. It would require a larger chip and more expense.

You can use our method or the opposition. Just be aware that the two are

not interchangeable.

Ours is classified as the lowest "form" (level) of programming - commonly called

machine code - invented in the early days of microprocessors - and now

called mnemonic programming as each line of code is made up of

letters of a set of words. The opposition uses a higher level language

where one instruction can carry out an operation similar to a

sub-routine.

But you have to learn the "higher level language" in order to create a

program. And this requires a fair amount of skill and capability.

It sounds great and it is a good idea. But if you want to learn PIC

programming, it does not assist you. It is "a step removed" from

learning PIC language. The other disadvantage of the opposition is the

"overhead." The 1,000 spaces allocated for your program is filled with

pre-written sub-routines. You may require only 10 of these sub-routines but ALL

of them are loaded in the memory space. And they take up all the memory.

You have no room for your own program.

To get around this the opposition uses a 93LC56 EEPROM to deliver

instructions on how to apply the sub-routines. This provides about 80 powerful instructions using their

language called BASIC (or a similar language).

It's a bit like selling a diary filled with all the paragraphs you need

to express yourself, and leaving a few blank pages at the back for you

to write single lines such as: see page 24, paragraph 7, see page 63

paragraph 4, to create your diary entries.

A detailed report on the BASIC Stamp-1 is HERE.

It depends on how much you want to be in charge of writing a program. Using

our method is like writing your own auto-biography. Using the opposition

is like getting a "ghost writer."

When using a higher level language to create a program, you have absolutely no

idea how the code is generated for the micro.

In some of the developmental kits, the code is "locked away" and you are

NEVER able to access it.

Everything runs smoothly until a fault occurs. With our method you can

see the code. With the other methods, you cannot see the code - it's

like doing key-hole surgery without the advantage of an

illuminated endoscope to see what you are doing.

Everything has its place and our method of hand-assembly is only

suitable for very small micros and you will eventually need to "learn a

high level language." The PIC12F629 has over 1,000 locations for code

and this equates to more than 20 pages when printed, so this is about

the limit to doing things by hand.

But our drive is to show how much can be done with the simplest devices

on the market, at the lowest cost.

Anyone can show you high-technology at a high price but this is not

where you start and this is not where you get enthusiasm.

We provide the things to get you started. That's the difference.

Many of the ideas

you want to do have already been done in our PIC Projects section, such

as driving a servo, producing a RUNNING SIGN, a LED chaser, an Audio

CRO, a Touch Switch, Displaying letters on an 8x8 matrix. PIC Fx project

has been developed for NEW ideas.

Almost any program you want to write will be able to utilize

sub-routines that have already been written.

That's why it is best to look at all the projects in the PIC Projects

section to familiarize yourself with what has been done.

You can then create a new program by copying and pasting routines onto

the new template.

No matter what you are doing, you have to build a program "one small

step at a time." This is to avoid frustration.

The biggest problem with any program is interfacing a switch.

Notes on this are on the website under WRITING A PROGRAM.

The other helpful tip is to produce a marker so you know what the micro

is doing.

The marker may be to let you know the contents of a file, or if the

micro has executed a certain sub-routine.

To do this you add a small routine to flash a LED or output a tone to a

piezo. You must be in control with each new sub-routine you add. It must

work before you go on to the nest next addition.

If you think you can write a program, AND IT WILL WORK FIRST TIME, you

are better than me and you don't need any advice.

No other site ASSISTS you in writing a program.

They all give the impression that everything will work as soon as you

turn on the power.

The only way you can guarantee success is to do things in small steps.

MODIFYING THE

PROGRAM

To write programs or modify the project is a whole new world of learning

and is covered in the next pages of this project.

To write a program you will need a PICkit-2 programmer.

The PIC Fx program does a bit of

detecting when turned on. It detects to see if a bit has been set in

EEPROM to tell the micro to go to a required sequence or start with

sequence 1.

It also detects if switch A, B or C has been pressed at the instant the

project is turned on so that the micro is directed to the sub-routine

where the user-sequence can be entered or if the EEPROM bit is to be

cancelled or if programs Code Lock, Reaction Timer or 4-Alarm sounds are

being accessed.

All this gets done in the SetUp routine and then the micro goes to one

of the routines in the MAIN section of the program.

Increments a "jump" file and calls a table where it

finds a directive to go to a particular sub-routine.

The sub-routine is executed and the micro goes back to Main where it

looks for a release of SwA. This forms part of a key debounce as the key

must be fully debounced as it is advancing the micro through the

sequences.

To provide a totally reliable debounce, the key is detected as not being

pushed for the duration of a whole cycle of a sequence and a separate loop is then executed where the key can be

detected as being pushed, to advance the program to the next sequence.

To create your own sequence as sequence1, the project is turned off and

SwA pressed while turning the project ON.

This sends the micro to a sub-routine called Attract.

As soon as SwA is released, the program starts to time the duration when

a switch is not pressed and it "times-out" after 2.5 seconds.

The program also times the duration when a LED is illuminated. It also

accepts 2 or 3 LEDs illuminated at the same time. These are all clever

instructions that need to be looked at to see how they operate.

Up to 15 steps can be entered and each step occupies three bytes. The

first value identifies the illuminated LEDs, the second byte identifies

the ON duration (in increments of 5mS) and the third byte identifies the

OFF time.

These 45 bytes are contained in files 30h to 5Fh.

When a switch is not pressed for 2.5 seconds, the program "times out"

and sends the values to the EEPROM. It then shows the sequence on the

LEDs.

If the project is turned off and on again, this sequence will be

displayed as sequence1.

To replace the sequence with something else, simply repeat the steps above.

If you want one of the pre-programmed sequences to appear each time the

project is turned on, simply advance through the sequences by

pressing SwA and when the desired sequence is playing, push SwB.

This will record your choice. Turn the project OFF then ON again and the

chosen sequence will be displayed.

To remove this feature, press SwC when the project is off and at the

same time, turn the

project ON.

All these feature have been added to the program, one at a time, and it

is important to add them in the correct order. For instance, you can only add a removal feature after the

initial feature has been produced. Reading and writing to the EEPROM is

a most complex operation and the instructions must be laid out as shown

in the program, as they include a hand-shaking sequence. When you need this

code it is copied and

pasted in its entirety, to prevent a mistake.

Nearly every instruction has a comment to explain not only what it does, but why it was chosen.

If you think you can start programming without reading programs from

other developers, you are wasting your time.

No individual can work how to do many of the tasks via the simplest set

of instructions and you will find some programmers have used complex

code to do the simplest task.

That's why you have to pick out the "wheat from the chaff" and

remember a good routine, while discarding the over-complex sets of code.

This brings up an important point.

Don't expect to be an A1 programmer in a week. It takes time to absorb

the skills of programming and it is really only understood by a

microscopic percentage of electronics enthusiasts. If you take it up and

understand it, you are one of the microscopic few.

It is a world that, once you are in, will open up a whole new field of

ideas and development.

It's like taking up a new spoken language and, in fact, a program reads

like a book, so the analogy is very close.

There are some very "clever" instructions such as XOR where you can

compare two files by using the XOR function and determine if they are

the same. And very powerful instructions such as djnz that decrements a

file and if it is zero, the micro jumps over the next instruction.

Other clever instructions transfer the contents of a file to another via

the "carry."

You cannot be expected to know these "tricks" unless you

study programming. That's why we are here.

Here are the files you will need:

LED_FX.asm

LED_FX-asm.txt

LED_FX.hex

;*******************************

;;PIC Fx.asm

; 11-3-2010

;*******************************

list p=12F629

radix dec

include "p12f629.inc"

errorlevel -302 ; Don't complain about BANK 1 Registers during assembly

__CONFIG _MCLRE_OFF & _CP_OFF

& _WDT_OFF & _INTRC_OSC_NOCLKOUT ;Internal osc.

;_MCLRE_OFF - master clear must be off for gp3 to work as input pin

;****************************************************************

; variables - names and files

;****************************************************************

temp1 equ 20h ;

temp2 equ 21h ;

temp3 equ 22h ;

temp4 equ 23h ;

jump equ 24h ;jump value for table1

fadeUp equ 25h

fadeDwn equ 26h

sequences equ 27h

sw_duration equ 28h

testing equ 29h

;****************************************************************

;Equates

;****************************************************************

status equ 0x03

rp1 equ 0x06

rp0 equ 0x05

GPIO equ 0x05

status equ 03h

option_reg equ 81h

; bits on GPIO

pin7 equ 0 ;GP0 LED C

pin6 equ 1 ;GP1 LED B

pin5 equ 2 ;GP2 LED A

pin4 equ 3 ;GP3 Sw A

pin3 equ 4 ;GP4 Sw B

pin2 equ 5 ;GP5 Sw C

;bits

rp0 equ 5 ;bit 5 of the status register

;****************************************************************

;Beginning of program

;****************************************************************

org 0x00

nop

nop

nop

nop

nop

SetUp bsf status, rp0 ;Bank 1

movlw b'11111000' ;Set TRIS GP0,1,2 out GP3,4,5 input

movwf TRISIO ;

bcf status, rp0 ;bank 0

movlw 07h ;turn off Comparator ports

movwf CMCON ;must be placed in bank 0

clrf GPIO ;Clear GPIO of junk

call _memory

btfss gpio,5 ;SwA to: "record new sequence"

goto record

btfsc gpio,3 ;SwC removes attract sequence

goto $+.10

movlw 0FFh

bsf status,rp0 ;select bank1

movwf EEDATA

bcf status,rp0 ;select bank0

movlw .101

bsf status,rp0 ;select bank1

movwf EEADR

bcf status,rp0 ;select bank0

call write

movlw .101

bsf status,rp0

movwf EEADR

bsf EECON1,0 ;starts EEPROM read operation. Result in EEDATA

movf EEDATA,w ;move read data into w

bcf status,rp0

xorlw .8 ;look for 8 - for Attract mode

btfsc 03,2

goto Attract_Seq ;selected sequence will appear first

goto Main

;****************************************************************

;* Tables *

;****************************************************************

table1 addwf PCL,F ;02h,1 add W to program counter

retlw .10 ;

retlw .50

retlw .30 ;

retlw .50

retlw .100 ;

retlw .40 ;program starts at bottom of table

retlw .10 ;

retlw .50

retlw .30 ;

retlw .50

retlw .60 ;

retlw .10 ;

retlw .50

retlw .10 ;

retlw .50

retlw .100 ;

retlw .20 ;

retlw .50

retlw .30 ;

retlw .50

retlw .70

retlw .60 ;

retlw .100 ;

retlw .50

retlw .100 ;

retlw .50

retlw .100 ;

retlw .70 ;

retlw .50

retlw .30 ;

retlw .50

retlw .70 ;

table2 addwf PCL,F ;02h,1 add W to program counter

goto seq1

goto seq2

goto seq3

goto seq4

goto seq5

goto seq6

goto seq7

goto seq8

goto seq9

goto seq10

goto seq11

goto seq12

;****************************************************************

;* Delays *

;****************************************************************

_xuS movwf temp2

_uS movlw .10

movwf temp1

decfsz temp1,f

goto $-1

decfsz temp2,f

goto _uS

retlw 00

_ZuS movwf temp2

goto $+2

goto $+2

decfsz temp2,f

goto $-3

retlw 00

_xmS movwf temp2

_x nop

decfsz temp1,f

goto _x

decfsz temp2,f

goto _x

retlw 00

;5mS delay for increments in timing for "New Sequence"

_5mS movlw 05h

movwf temp2

_5 nop

decfsz temp1,f

goto _5

decfsz temp2,f

goto _5

retlw 00

_10mS movlw 0Ah

movwf temp2

_10 nop

decfsz temp1,f

goto _10

decfsz temp2,f

goto _10

retlw 00

_50mS movlw .50

movwf temp2

_50 nop

decfsz temp1,f

goto _50

decfsz temp2,f

goto _50

retlw 00

_100mS movlw .100

movwf temp2

_100 nop

decfsz temp1,f

goto _100

decfsz temp2,f

goto _100

retlw 00

_150mS movlw .150

movwf temp2

_150 nop

decfsz temp1,f

goto _150

decfsz temp2,f

goto _150

retlw 00

;****************************************************************

;* Sub Routines *

;****************************************************************

_memory

movlw .48

movwf temp1

movlw 2Fh

movwf fsr

incf fsr,f

movlw 0FFh

movwf indf

decfsz temp1,f

goto $-4

retlw 00

;SwB puts current sequence into EEPROM for turn on.

;and puts "marker" in location 101

Attract

movf sequences,w ;put sequence number into w

bsf status,rp0 ;select bank1

movwf EEDATA

bcf status,rp0 ;select bank0

movlw .100

bsf status,rp0 ;select bank1

movwf EEADR

bcf status,rp0 ;select bank0

call write

movlw .8

bsf status,rp0 ;select bank1

movwf EEDATA

incf EEADR,1

bcf status,rp0 ;select bank0

call write

nop

goto $-1 ;Project must now be turned off

;Seq selected as Attract will be displayed when project turned on

Attract_Seq

movlw .100

bsf status,rp0

movwf EEADR

bsf EECON1,0 ;starts EEPROM read operation. Result in EEDATA

movf EEDATA,w ;move read data into w

bcf status,rp0

movwf temp4

movf temp4,w

call table2

goto $-2

;record new sequence - looks for "no switch pressed" for 1.25 seconds to exit

;uses files 30h to 5Fh (48 files)

;three files per "step" 1st file = LEDs, 2nd = Off time, 3rd = on time

;15 steps allowed - look for 5Dh

record btfss gpio,5 ;wait for release of button A

goto $-1

movlw 30h

movwf fsr ;start storage at file 30h

;look at keys being pressed - identifies 2 or 3 keys pressed together

_r1 clrf sw_duration

_r1a call _5mS

incfsz sw_duration,1 ;5mS x 256 = 1.25seconds

goto $+2

goto Store ;time out! store files 30h to 5Fh in EEPROM

btfss gpio,5 ;see if one or more Sw is pressed

goto $+5

btfss gpio,4

goto $+3

btfsc gpio,3

goto _r1a ;no sw pressed create 2.5 sec timing

;1,2,or 3 sw pressed

call _10mS ;delay to detect 2 or 3 switches

incfsz sw_duration,1

goto $+2

goto Main

btfsc gpio,5 ;SwA

goto $+2

bsf gpio,0 ;turn on LED A

btfsc gpio,4 ;SwB

goto $+2

bsf gpio,1 ;turn on LED B

btfsc gpio,3 ;SwC

goto $+2 ;

bsf gpio,2 ;turn on LED C

;LEDs have been illuminated

movf gpio,w

movwf indf ;w moved to fsr's file (30h+)

incf fsr,f

movf sw_duration,w ;off time!!

movwf indf ;w moved to fsr's file (30h+)

incf fsr,f

clrf sw_duration

_r2 call _5mS

incfsz sw_duration,1

goto $+2

goto record ;time out! keys pressed too long. Start again

btfss gpio,5

goto _r2 ;sw pressed

btfss gpio,4

goto _r2 ;sw pressed

btfss gpio,3

goto _r2 ;sw pressed

;file empty. Put duration into file

movf sw_duration,w ;on time

movwf indf ;w moved to fsr's file (30h+)

incf fsr,f

movlw 5Dh

xorwf fsr,w

btfss 03,2

goto $+2

goto Store ;stop at 15 steps. store files 30h to 5Fh in EEPROM

clrf gpio

goto _r1

;sequences:

;seq1 Self-Programmed sequence

;1St file:LEDs 2nd file:OFF time 3rd file:On time

seq1 bsf status,rp0

clrf EEADR

bcf status,rp0

bsf status,rp0

bsf EECON1,0 ;starts EEPROM read operation. Result in EEDATA

movf EEDATA,w ;move read data into w

bcf status,rp0

movwf gpio

bsf status,rp0

incf EEADR,1

bsf EECON1,0 ;

movf EEDATA,w ;move read data into w

bcf status,rp0

movwf temp4 ;this is OFF time. Store it

bsf status,rp0

incf EEADR,1

bsf EECON1,0 ;

movf EEDATA,w ;move read data into w

bcf status,rp0

movwf sw_duration ;this is ON time

call _5mS

decfsz sw_duration,1

goto $-2

clrf gpio

call _5mS

decfsz temp4,f ;create OFF duration

goto $-2

bsf status,rp0

incf EEADR,1

bsf EECON1,0 ;

movf EEDATA,w ;move read data into w

bcf status,rp0

xorlw 0FFh ;look for 0FFh - end of routine

btfss 03,2

goto $-31

retlw 00

;seq2 chase right - very fast

seq2 bsf gpio,0

call _100mS

bcf gpio,0

bsf gpio,1

call _100mS

bcf gpio,1

bsf gpio,2

call _100mS

bcf gpio,2

call _100mS

clrf gpio

retlw 00

;seq3 chase right

seq3 bsf gpio,0

call _150mS

bcf gpio,0

bsf gpio,1

call _150mS

bcf gpio,1

bsf gpio,2

call _150mS

bcf gpio,2

call _150mS

clrf gpio

retlw 00

;seq4 chase right with off-delay at end

seq4 bsf gpio,0

call _150mS

bcf gpio,0

bsf gpio,1

call _150mS

bcf gpio,1

bsf gpio,2

call _150mS

bcf gpio,2

call _150mS

retlw 00

;seq5 left right left right

seq5 bsf gpio,0

call _150mS

bcf gpio,0

bsf gpio,2

call _150mS

bcf gpio,2

retlw 00

;seq6 middle on middle off

seq6 bsf gpio,1

call _150mS

bcf gpio,1

call _150mS

clrf gpio

retlw 00

;seq7 All on all off

seq7 clrf gpio

call _150mS

decf gpio,f

call _150mS

clrf gpio

retlw 00

seq8 ;seq8 middle on then sides on

bsf gpio,1

call _150mS

bcf gpio,1

bsf gpio,0

bsf gpio,2

call _150mS

clrf gpio

retlw 00

;seq9 police flasher 3 times left 3 times right

seq9 bsf gpio,0

call _50mS

bcf gpio,0

call _50mS

bsf gpio,0

call _50mS

bcf gpio,0

call _50mS

bsf gpio,0

call _50mS

bcf gpio,0

call _50mS

bsf gpio,2

call _50mS

bcf gpio,2

call _50mS

bsf gpio,2

call _50mS

bcf gpio,2

call _50mS

bsf gpio,2

call _50mS

bcf gpio,2

clrf gpio

call _50mS

retlw 00

;seq10 random flicker

seq10 movlw .32 ;start at bottom of table

movwf jump

bsf gpio,1

movf jump,w ;put table jump value into w

call table1

call _xmS

bcf gpio,1

decfsz jump,f

goto $+2

retlw 00 ;top of table found

movf jump,w ;put table jump value into w

call table1

call _xmS

goto $-11

;seq11 slow fade up down

seq11 clrf fadeUp ;

clrf fadeDwn

incf fadeUp,f ;to create 1 (delay routine does not like 00)

bsf gpio,1

movf fadeUp,w

call _xuS

bcf gpio,1

movf fadeDwn,w

call _xuS

decfsz fadeDwn,f ;

goto $-8

incf fadeDwn,f ;to produce 1

bsf gpio,1

movf fadeUp,w

call _xuS

bcf gpio,1

movf fadeDwn,w

call _xuS

decf fadeUp,f

incfsz fadeDwn,f

goto $-8

clrf gpio

retlw 00

;seq12 fast fade up down

seq12 clrf fadeUp

clrf fadeDwn

incf fadeUp,f ;to create 1 (delay routine does not like 00)

bsf gpio,1

movf fadeUp,w

call _ZuS

bcf gpio,1

movf fadeDwn,w

call _ZuS

decfsz fadeDwn,f ;

goto $-8

incf fadeDwn,f ;to produce 1

bsf gpio,1

movf fadeUp,w

call _ZuS

bcf gpio,1

movf fadeDwn,w

call _ZuS

decf fadeUp,f

incfsz fadeDwn,f

goto $-8

clrf gpio

retlw 00

;Store Store the 15 steps in EEPROM

Store bsf status,rp0 ;select bank1

clrf eeadr

bcf status,rp0 ;select bank0

movlw .48

movwf temp1

movlw 2Fh

movwf fsr

incf fsr,f ;fsr starts at file 30h

movf indf,w ;retreive data in file 30h

bsf status,rp0 ;select bank1

movwf eedata ;

bcf status,rp0 ;select bank0

call write

bsf status,rp0 ;select bank1

incf eeadr,1

bcf status,rp0 ;select bank0

decfsz temp1,f

goto $-10

goto Main

write bsf status,rp0 ;select bank1

bsf eecon1,wren ;enable write

movlw 55h ;unlock codes

movwf eecon2

movlw 0aah

movwf eecon2

bsf eecon1,wr ;write begins

bcf status,rp0 ;select bank0

writeA btfss pir1,eeif ;wait for write to complete

goto writeA

bcf pir1,eeif

bsf status,rp0 ;select bank1

bcf eecon1,wren ;disable other writes

bcf status,rp0 ;select bank0

retlw 00

;****************************************************************

;* Main *

;****************************************************************

Main clrf sequences

movf sequences,w

call table2

btfss gpio,5 ;Is swA still pressed?

goto $-3 ;SwA still pressed

movf sequences,w ;SwA released

call table2

btfss gpio,4 ;SwB puts current sequence at turn-on

goto Attract

btfsc gpio,5

goto $-5 ;SwA not pressed

incf sequences,f

movlw .12

xorwf sequences,w

btfss 03,2

goto $-12

goto Main

;****************************************************************

;*EEPROM *

;****************************************************************

org 2100h

END

GOING

FURTHER

We have not produced all the

possible sequences and you can add more by simply creating

a new sub-routine.

You need to add it to the table and make sure you end with retlw 00

to send the micro back to Main.

We have provided all the hardware and software for you to do this. Now

it's now up to you.

Parts List

Cost:

au$12.00

plus postage

Kits

are available

3

- 82R (820) SM

resistors

2 - 22k (223) SM

resistors

2 - 47k (473) SM

resistors

1 - 100n SM capacitor

1 - 10u tantalum

1 - SPDT mini slide switch

1 - LM78L05 voltage

regulator

1 - PIC12F629 chip (with

routines)

1 - 8 pin IC socket

3 - super bright white 3mm LEDs

3 - mini tactile switches

5 - machine pins

5 - component header pins

(alternative)

5cm fine tinned copper wire for link

1 - piezo diaphragm

1 - 9v battery snap

20cm very fine solder

1 - PIC Fx-1 PC board