|

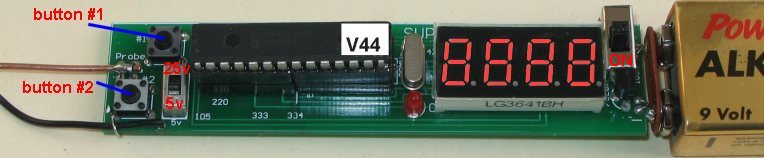

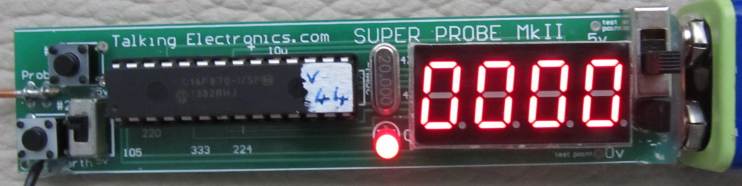

SUPER PROBE MkII |

|

|

This project

has been adapted and modified from a project designed by Luhan Monat of mondo-technology.com

The original project has been changed slightly with an added feature but

retaining the simplicity of the circuit

and the code. It just goes to show what can be done with a simple

microcontroller and a set of instructions.

This is by far the most complex project we have ever described and it

should be thoroughly investigated to see exactly how each function has

been designed and how the external components are "switched into

circuit" to charge and discharge the component being tested.

By looking at sites on the web you will see this has

been a very popular project but no-one has

provided a kit of components to build it. That's what we have

done.

We have added one extra feature (Voltage: 0 to 25v) and provided a pre-programmed PIC chip

and a complete kit of parts for a total of $18.00 plus postage.

The case is extra and can be purchased from one of the suppliers mentioned below.

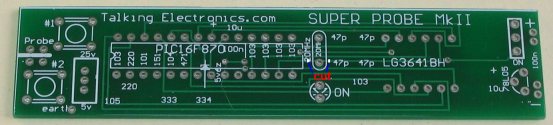

The project is built on a Printed circuit board 22mm x 100mm and comes with a pre-programmed chip, surface mount components,

4-digit display,

5v6 zener diode, 20MHz Xtal,

regulator, switches, very fine solder, wire and battery clip. You would normally

need to go to more than 3 different suppliers and also get

someone to program the chip. We have done it all for you and

modified the program to reduce the flicker (the strobing effect

that separates the segments when the display is moved).

The project does an enormous number of things and you have to study the

list of functions to see how each function works and the features within

each function.

|

To cycle through the 20 functions, turn the

Probe ON and the centre segment of the first display will

illuminate. |

If a pulse

(0.5us) is detected, the second

display flashes 'P'.

Here are the

details of the 20 functions:

Prob

Logic Probe

Logic Probe shows the first position

of the

display:

PULS

Logic Pulser

The

Logic Pulser shows the pulse rate (5, 50, 500, 5.0) in the last

3 locations. The first location shows the sensed logic level as

a dash in the bottom or top of the digit. When button #1 is

held down, a series of 0.5 microsecond pulses are generated in

the opposite direction and the center segment is lit. Pushing

button #2 cycles thru the 4 pulse rates. The selected pulse

rate is saved on power down.

FrEq

Frequency Counter

In

the Frequency Counter mode, pushing button #1 switches the

display to the next 4 digits of the count. For instance, the

display shows '12.57' for a frequency of 12,576 Hz. Holding

down button #1 shows '2576' - the lowest 4 digits. If a decimal

point shows, the value is in KHz, if the decimal is flashing,

the value is in MHz. Hence, a frequency of 42,345,678Hz is

displayed as 42.34 with a flashing decimal. Holding down button

#1 will display 5678.

Cnt

Event Counter

In

the event count mode, the display shows the lowest 4 digits.

Button #1 switches to the next higher 4 digits while held down.

Button #2 resets the count.

VoLL

Voltmeter

Switch the 5v_25v

switch to 5v. The

project uses the 5v from the regulator as a

reference. Do not connect the probe to voltages

above

5 volts.

VoLH

Voltmeter

Switch the 5v_25v

switch to 25v. The display measures voltage to 25v. Do not connect the probe to voltages

above 45 volts as the probe does not detect anything above 25v

and the components are not rated for high voltages. The 1M is

the "protection resistor." in the voltage divider.

diod

Diode Junction Voltage

This

is just the voltmeter function with a 10k resistor feeding current

to the probe tip. When a diode or transistor junction is

connected from the tip to the ground lead, the drop voltage is

displayed.

LEdS

LED

voltage drop

Measures the characteristic

voltage drop across a LED @3mA.

Ideal for detecting cathode lead and matching

LEDs.

(29-6-2011)

Approx 0.1v is dropped across 22R so take 0.1v

from LED reading.

LOW Battery is detected by open probes

reading less than 5.95v

Cap

Capacitance Measurement

READ THESE NOTES:

When

a capacitor is connected from the tip to the ground lead and

button #1 is pushed, its value is displayed. Values from .001 uf

(1n or 1,000p) to about 500 uf are displayed. The larger the capacitor, the

longer it takes to measure. A value of 100uf takes a couple of

seconds.

To do this, turn the Probe OFF. Fit the

electrolytic to the leads. Turn the Probe ON. It

will display CAP and then go blank while it

reads the value of capacitance. It will then

display the value.

Coil

Inductance Measurement

When

an inductor is connected from the tip to the ground lead and

button #1 is pushed, its value is displayed. Values from 0.1mH

(100nH)

to 999.9 millihenries are displayed. Note: this function

assumes the DC resistance is not more than a few ohms.

Also, if the unit gets 'stuck' in this mode, jumper the tip to

ground to free it.

SIG

Signal Generator

This

mode generates a 500Hz square wave at about 0.5 volts. The

signal is only generated while button #1 is held down.

ntSC

Video Pattern

Generates an NTSC video frame with a white dot pattern.

SEr

Serial Ascii

Each

time button 1 is pushed, the letters A-Z followed by cr/lf is

generated. Auto polarity sensing. If the signal injection

point is originally high, then normal (zero start bit) ascii is

generated. Otherwise, the opposite polarity is created. New feature:

Button #2 cycles thru 1200, 2400, 4800, 9600 baud.

Midi

Midi Note

Sends

note middle C on any of the 16 midi channels.

Holding button 1 sends 'note on'. Release of button 1 sends

'note off'. Button 2 cycles thru the 16 channels. The midi

channel number is stored.

R/C

R/C Servo

Generates 1mS to 2mS pulse for r/c servos. Button 1 increases

pulse, Button 2 decreases pulse. Defaults to 1.5mS each time

mode is entered.

_|¯|_|

Square Wave

Generates 1 - 9999 Hz Square Wave. Button 1 decreases

frequency, Button 2 increases frequency.

noiS

Pseudo Random Number

Generates 10kHz digital PRN series - commonly called :White

Noise."

ir38

IR LED

Generates 1 millisecond ON and 2.5 millisecond OFF - 38kHz

square wave. When connected to IR LED, used for testing IR

receiver modules.

PWM

Pulse

Width

Modulation

Generates variable pulse-width 3% to 97% of a 6kHz (approx)

digital signal. Button 1 decreases pulse-width, Button 2

increases pulse-width.

StOP

Stop Watch

Button 1 starts/stops timer.

Change of state on probe tip also will start/stop timer. Button

2 resets timer. Timer

counts in 1/100 second from 0-99 seconds, then counts in 1/10

second from 100 -999 seconds.

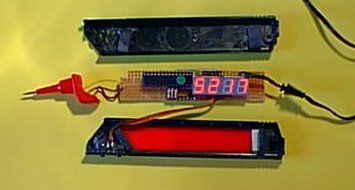

The original project is from Mondo Technology.

The case was a broken Logic Probe from Radio Shack - but see the

brightness of the display. It is perfectly viewable when each segment is

accessed individually. This is the way the display is accessed in the

program. It is a rather unusual way to scan the display but has two

features. It allows the outputs of the chip to be connected directly to

the display without putting too much strain on the FETs and

produces equal illumination for all segments.

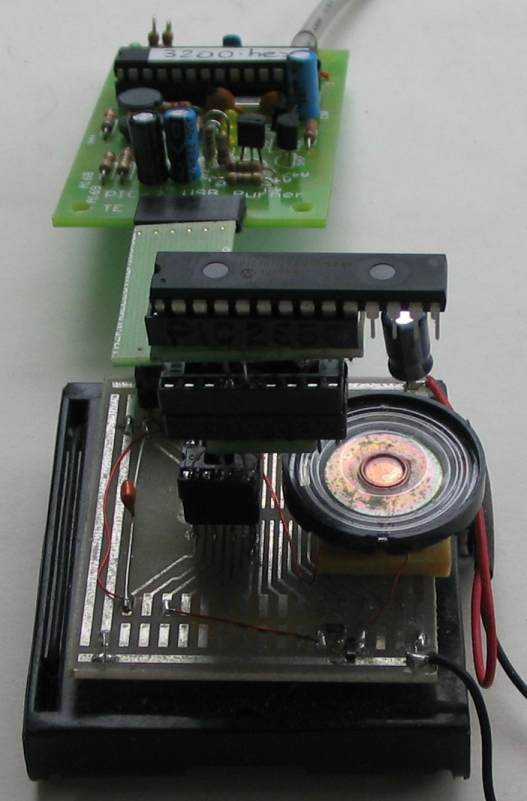

Here is the Super Probe from Heli:

Here is a Probe case "U-SONDA3" and tip.

"U-SONDA-tip," from

GM Electronic Slovakiaa: (cost: about

$3.00 USD including tip, plus postage):

Here is the Super Probe from:

http://ikon.wz.cz/mondo/sonda_2.php,

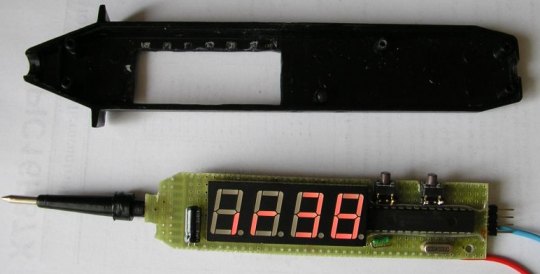

with the PC board and top-half-shell of the case: Here is a Logic Probe case from

Kelvin, for $3.75 plus postage, but they require a minimum $150 order!!

Here is a

Logic Probe case from

Rapid Electronics: It costs $10.50 plus postage.

The CIRCUIT

http://heli.xbot.es/SuperProbe/SuperProbe.htm

External size excluding tip (mm):145 x 30 x 21 Window size (mm):95 x 19

Order code:31-0330

Super Probe MkII Circuit

The circuit is very simple. It

uses a PIC 16F870 microcontroller connected directly to a 4 digit

display.

All the segments are connected together to reduce the wiring to 14 pins. No current limiting resistors have been used

between the micro and display and this means the

voltage-drop will be across the FETs inside the micro.

The display is illuminated ONE SEGMENT AT A TIME. And this means it

takes 4x7=28 to display all the segments (plus extra for the decimal

points). You would think the display

would be very dull. But this is not so. The display we have supplied in

the kit is "super-bright red" and although each segment is seeing only a duty

cycle of about 3-4%, the overall brightness is perfect.

During each segment illumination, we have one output of the chip driving

HIGH and one driving LOW. The LED drops 1.7v leaving 1.65v across

the top FET and 1.65v across the lower FET. This is overdriving the FETs

but thy do not seem to suffer.

The current taken by the project is 20-30mA. The rest of the components

are connected to the probe tip to create different charging and

discharging values for testing capacitors and inductors and for the 25v

voltage range.

The crystal needs 2 capacitors and the buttons need pull-up resistors (portB is the only port with weak pull-up resistors). The 249k is

created with a 220k and 33k in series. The 22p capacitors are created

with 2x47p caps in series and the kit contains 4x47p surface-mount.

The brightness of the

display is superb

Click HERE for larger image

Here is the Super Probe constructed by Ahyan Yilmaz of Kocaeli TURKEY:

Note: the link is now a track on the top side of the board. No

tracks need to be cut with the new PCB's

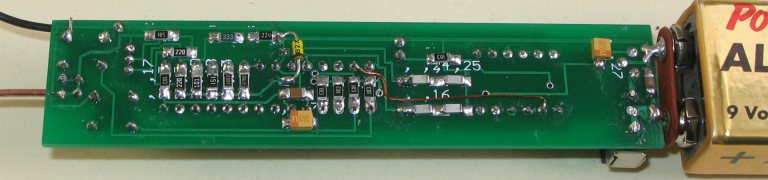

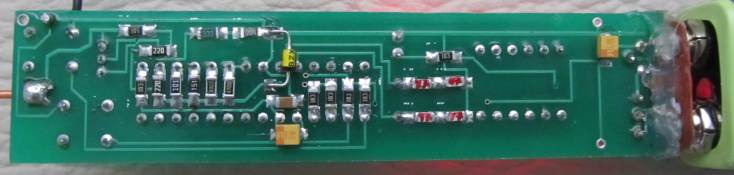

Surface-mount certainly makes a very neat project. The secret is the use of 0.8mm solder.

SURFACE-MOUNT COMPONENTS

We have used SM components to make the

project as small as possible.

They also make it look simpler as they "disappear" under the

board.

You will need fine tweezers to hold

them in place while one end is soldered to a pin of the 28 pin IC socket.

Using very fine solder (supplied in the kit) makes soldering easier and quicker. Always solder resistors with the value

showing.

CONSTRUCTION

This project is for medium-to-advanced constructors as

it is very compact. It is

built on a double-sided PCB and the kit comes with all parts, including a pre-programmed chip.

They are fitted

as shown in the photos above.

Two tracks need to be cut near the crystal and a link fitted under the board.

When the IC socket and display are fitted, they are soldered in place.

The next thing is fit the crystal, switches, regulator and then the

surface-mount components. Tin one pad then fit the surface-mount

component. Use fine tweezers. Now solder the other pad and the solder

will run under the chip. Don't forget to cut the two tracks next to the

crystal and join the track with a short length of enamelled wire. Fit

the regulator and short lengths of tinned copper wire in the holes for

the battery snap.

Twist the wires together and cut them short so they just fit through the

hole in the battery snap. Tin the wires and fit the battery snap and

solder the wires to the snap. Refer to the photo above to see how the

snap is connected.