|

THE WASP |

TESTING, ALIGNING and GETTING THE CIRCUIT TO WORK

We are going to cover these three at the same time.

The first thing to do is see if the transmitter works. This will relieve a lot of your worries.

Place it near an FM radio turned to medium volume and tune across the dial, listening for

a feedback squeal.

If a squeal is heard, the transmitter is operating on the FM band. If you don't hear a squeal,

you should read on:

Don't worry if you don't hear a squeal as the circuit may be operating just below the band and

in this case you will not be able to pick it up.

To find out, remove the antenna lead and fit the LED Power Meter.

It will only take 10 minutes or so to build this circuit and connect it to an ordinary

multimeter set to low volts range.

THE LED POWER METER

The LED power Meter is a simple RF detector using diodes to charge

a capacitor. The voltage developed across the capacitor is shown on

a multimeter set to a low voltage range. The circuit is soldered together

without the need for a PC board, as can be seen in diagram below and paper

clips are used for the positive and negative terminals of the multimeter.

The

power from the output of the Wasp is indicated by the illumination

of a LED and the voltage reading on the multimeter gives a further

indication of the output.

The reading is not calibrated and does not represent milliwatts output.

It is only a visual indication.

|

LED Power Meter Parts List |

| 1 - 470R 1 - 100pF ceramic 1 - 0.1uF (100n) ceramic 2 - 1N 4148 diodes 1 - 2in (5cm) hook-up wire 2 - paper clips No PC board required |

If the multimeter does not show a reading, the output stage is not working.

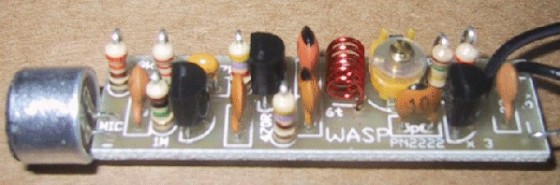

The Complete Wasp showing how the components are

mounted close to the board

Connect the LED Power Meter to the collector of the oscillator and see if a reading is produced.

If not, a fault exists and you will have to find it.

Each of the stages in this project are AC coupled (a capacitor separates them) and they can be

tested individually.

The first place to go to is the oscillator section.

This is a difficult stage to test as it is operating at a very high frequency.

It is not possible to view the waveform on an ordinary 30MHz CR0 as the circuit is operating at

90MHz and the CR0 will not display the waveform on the screen. All it will show is a mass of lines

- if you are lucky. A 30MHz CR0 will also put such a load on the circuit that it will cease

to oscillate.

This means all you can do is take a few voltage measurements and check the continuity of the

trackwork.

Firstly check the voltage on the collector of the oscillator transistor. It should be 3v,

indicating the coil is making contact through the board. Next measure the voltage on the

emitter. It should be about 2v. If it is 0v, the transistor is not being turned on or the 470R is

not making contact through the board (the voltage will be about 2.5v – 3v, in this case).

The base voltage should be about 2.6v, and if it is much lower than this, the 47k resistor

may be the wrong value or the transistor is pulling the voltage down (due to the emitter

resistor being the wrong value

and/or the base-emitter junction being a short circuit).

When you are probing around this stage, the load produced by the leads of the multimeter will

often prevent the circuit from operating, so don't expect to get an output on the LED Power

Meter when probing the board.

The main reason for this is the leads become an antenna and they absorb the signal.

The LED Power Meter can be connected all the time. It puts a very small load on the circuit

and will not affect the performance.

Three problems remain. You cannot test the air trimmer when it is in circuit as the coil

across it has a very low resistance. If you want to see if the air trimmer is shorting, you

will have to remove the coil.

Secondly you cannot test the 39p unless you remove it and test it on a Capacitance Meter.

The same applies to the 10p. The cheapest and quickest thing to do is replace the two

components.

The 1n is also very important and if it has been damaged during assembly (open circuit),

the oscillator will not function. This should also be replaced.

Lastly the 22n across the power rails must be in place to get a good output from the

oscillator. Try another 22n across it to see if the performance alters. The only other

things I can suggest are a shorted or damaged 100n input capacitor and/or 10p output

capacitor, as well as a damaged transistor. Use de-solder wick to remove the solder so

that the transistor can be removed easily, without lifting the lands off the

PC board

This time, take more care with soldering as the most probable cause of the transistor

being damaged is due to overheating during soldering.

Obviously you will have checked the freshness of the cells, to make sure the voltage is

not too low, and the operation of the switch.

Just in case you are not aware, you cannot connect this project to a power supply or to

cells via long leads. The length of the leads will reduce the "tightness of the circuit”

and prevent the oscillator from functioning properly. You can however, connect it to C or D

cells to get up to 6 months of continual operation. This should get the oscillator functioning

and you can now go to the antenna point and measure the RF via the LED Power Meter. If there

is no reading, the fault will lie in the output stage. This consists of an output transistor,

150k base bias resistor, 10p coupling capacitor and a 330R collector resistor.

Measure the voltage on the collector. It should be very close to 1.5v and the voltage on the

base should be about .65v, indicating the transistor is turned on via the 150k resistor.

There is little more you can do to test this stage as it is operating at very high frequency.

Don't forget the possibility that the transistor is damaged due to soldering (or maybe a short

between tracks on the board).

You must get a reading on the antenna-point before continuing.

SETTING THE FREQUENCY

The next step is to set the frequency of operation.

This could be below the FM band or above it as the commercial section between 88 and 108MHz is

rapidly filling up.

When we first started producing transmitters the band was almost totally empty, but as

minority groups have begun to realize the power of voicing their view on the airwaves, every

local community group has its own radio station.

The separation between radio stations is now less than 100kHz and you cannot get another

transmission in between.

Just above or below the dial is sometimes the best solution and we have opted for below the

band when we sell made-up devices, as this allows us to use low cost transistors.

Simply by adding one more turn to the oscillator coil we can tune below the band and adjust

the turns to sit between courier companies and other users.

When thinking of transmitting above the band, you cannot operate between 120MHz and 130MHz as

this has been allocated to the emergency band and aircraft traffic control.

Back to the project:

With a reading on the LED power Meter you know the Wasp is transmitting but you don't know the

frequency of transmission.

If you want to operate on the 88 -108MHz band, turn on an FM radio and tune across the band.

When the radio is at the same frequency as the Wasp, it will produce a loud squeal.

If you want to operate below the band you will have to detune the radio so that it will go

down to approx 86MHz.

This is done by moving the turns of the air-cored coil near the tuning gang so that the

stations move up the scale. This will create an empty spot at the lower end of the band.

You can also adjust the trimmers on the back of the tuning capacitor to shift the stations

up or down the dial.

In most cases you cannot shift the band very much as the stations begin to "wrap around”

the dial and the high stations appear at the lower end. Be satisfied with a small shift.

You should now tune the radio to the bottom of the band if you have detuned the radio, or

to the top of the band if you have moved the stations down.

For a detuned Wasp, you should have 7 turns in the oscillator coil. Move the turns of the

coil so that you get a feedback whistle.

If you want to transmit above the commercial band, make sure you have 5 turns on the coil.

One of the main problems with this part of the operation is finding out the frequency of

transmission. The LED Power Meter will not give you this; it will only let you know when

the oscillator is operating.

You need a frequency meter or our FIELD STRENGTH METER MklI (to be described in

a future issue). It has a scale marked on the

PC board, from 75MHz to 140MHz to let you know the frequency of the signal you are picking

up and a set of 3 LEDs to indicate the relative strength of the signal.

If you get a reading on the LED Power Meter and an indication on the Field Strength Meter

Mkll to indicate the frequency is say 90MHz, but the radio only produces a dead spot or

quiet spot on the dial, it will indicate the audio from the first stage is not coming

through.

This means the fault will lie in the audio amplifier stage and/or electret microphone.

The first thing to do is take voltage tests and confirm your readings against those

given on the circuit diagram. The collector of the audio transistor should be about

half rail voltage (and the voltage on the microphone can be as low as 50 millivolts)

and the microphone will still be working perfectly.

To test these stages more fully you need an audio oscillator or audio probe and we

have provided an audio injector probe on the Combo-2 project. (This

will also be described in a future issue).

Connect the earth clip of the Combo-2 project to the negative rail of the Wasp and

inject a signal at the collector of the audio stage.

This will send a tone through the 100n coupling capacitor and produce a buzz

from the radio.

If this does not happen, the fault will lie in the 100n monoblock or maybe the end of the capacitor

that goes to the collector of the audio stage has a short under the board, taking it to one of

the rails and thus shorting out the signal.

Once you get a signal at this point, move the probe to the base of the audio transistor. The buzz

from the radio should be louder.

If it is weaker, the audio transistor may not be amplifying correctly. It may be damaged or open

circuit.

Next, take the audio probe to the output of the microphone. If the output from the radio is reduced,

the 22n coupling capacitor may be open circuit or one of the ends may be shorted to the negative

rail.

If the output point of the electret microphone produces a loud buzz from the radio, but the

microphone does not produce any audio, the most likely cause is a faulty microphone.

Check around the microphone

for shorts and solder bridges. As a last resort, replace the microphone.

HAND-HELD MICROPHONE

As we said in the introduction, this project can be used as a hand-held microphone.

When using it in this type of situation, the microphone must be de-sensitised so that it is

not very sensitive. As the circuit stands, the microphone is very sensitive and will pick up

the ticking of a clock or a whisper from 3 metres away. This is too sensitive for a hand-held

situation, as the audio will be distorted. You can reduce the sensitivity by increasing the

microphone resistor from 39k to 68k or 100k.

The best idea is to put a 100k mini trim pot in series with the 39k (to act as a stopper

resistor) and turn the pot until the desired sensitivity is obtained.

HOUSING

The Wasp can be fined into a Tic Tac box so that the slide switch is just below the door.

Simply open the door and slide the switch on. Mark the "ON" position with "white out"

(Liquid Paper, etc) and cover this with bright red nail polish. Take the antenna through

a small hole in the bottom of the box. You can paint the box black, like we do with all

our made-up products and keep the lid from falling off with a small piece of sticky tape.

When using the bug, you can leave the door open or keep it closed; it doesn't seem to

make any difference. The audio gets to the microphone through the small gaps in the lid!

CONCLUSION

This completes the project.

We have covered everything in fine detail and hopefully one day you will come across a

microscopic fault such as a hairline crack in the trackwork, a component lead that has

not been pushed fully through the board, a hair bridge of solder or a slither of

trackwork at the end of the board and use the discussions we have provided to fix the fault.

This is the wonderful part of electronics. It lets you know if you don't get something

100% correct - the project doesn't work!

![]()