|

Capacitor Discharge Units |

Talking Electronics has produced 6 different projects

to control a set of points.

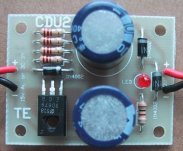

CDU-2 - solder leads to PCB. Comes with 2 x 1,000u electrolytics

CDU-2

CDU-2CDU-MkIIB - has screw terminals and 2 x 2,200u electrolytics.

CDU

MkIIB

CDU

MkIIB CDU using SPDT switch - comes with 2 x 1,000u electrolytics. Uses SPDT toggle switch.

(Or you can get 2 x 2,200u electrolytics at an extra $1.50 each)

CDU - In-line version - has screw terminals and a DPDT toggle switch soldered to the end of the board to make installation very easy.

CDU

In-line version

CDU

In-line version The following four projects use a motor, servo, linear actuator or Peco/Hornby Solenoid to move the rails.

Point Controller using a Linear Actuator

Point Controller using a Motor and Gearbox

Point Controller for a Peco/Hornby Solenoid

Point Controller using a Servo

These projects offer a very inexpensive way to turn a manual set of points into remotely controlled points and three of the projects detect the train and automatically set the points.

ACTUATING THE POINTS

There are a number of different point-actuating mechanisms on the market and some of them can get very hot or "burn-out" if a protection circuit, called a Capacitor Discharge Unit, is not fitted.

The controllers we are talking about are:

Peco/Hornby Solenoid Point Controller:

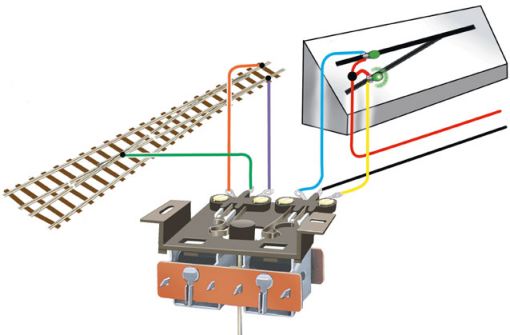

These are all the same design. They contain two coils (solenoids) to move a lever left or right.

Talking Electronics has 3 projects to control these "Motors" to prevent BURN-OUT. The projects use different types of switches.

Peco Point Motors are also available with two micro-switches to:

1. supply voltage to the "frog rail" in the centre of the point, and

2. Activate LEDs (or globes) on your control panel.

Here is the circuit:

Talking Electronics Capacitor Discharge Unit-2 (CDU-2) and CDU-MkIIB will operate these "motors" and prevent "burn-out."

CDU-2 connects to your layout by soldering 4 wires to the PC board. Cost $10.20

CDU-MkIIB has screw terminals so the project can be assembled and easily connected to your layout with a screwdriver. Cost $12.50

Here is the circuit:

CDU-2 and CDU-MkIIB can be controlled by:

CDU-2 and CDU-MkIIB can be controlled by: 1. Two separate push switches, or

2. A toggle switch with centre-off

If using a centre-off toggle switch, it must be returned to the centre-off position to allow the CDU-2 to re-charge the electrolytics.

3. Peco PL26 Passing Contact Switch.

If using a normal toggle switch, you need Talking Electronics project:

POINT CONTROLLER using TOGGLE SWITCH.

Cost: $13.50

You can also use a centre-off toggle switch with this project and it

does not have to be returned to the centre-off position.

The cam on the red lever closes the contacts on either the left or right side of the switch when the lever is passing from centre-position to end-position (50° to 70°) or (110° to 130°). You can see the slot at the point where the lever pivot has an effect of the positioning of the lever due to the spring-action of the lever containing a cup to hold the red lever hard against the pin and thus the right-side of the red lever will close the contacts on the right-side. This produces a brief "closing-time" for the Capacitor Discharge Unit to deliver a pulse of energy to the point motor.

The CDU project prevents the point motor burning out, just in case someone does not move the lever fully to the left or right position.

Peco PL-23 and PL-25 switches MUST include CDU units in the wiring to prevent "motor

burn-out." These switches do not have the brief

passing-contact-action of PL-26.

Other controllers are large and expensive:

Tortoise Point Controllers need to be mounted UNDER your layout and this may be impossible. Talking Electronics has a project using a slow-moving miniature linear screw actuator mounted on top of your layout. It is cheaper, smaller and the circuit contains an IR detector to detect a train and automatically change the point.

The project is designed to alternately take the train to the "siding" or "ahead" and when combined with the COPYCAT-1 project, you can produce a very interesting automatic operation on your layout.

Tortoise Slow moving Point Controller can be replaced

with Turtle Point Controller-1 using a servo to

provide the action to change the point. It is mounted on the top-side of

your layout. This project also includes an automatic feature where the

point is alternative changed from "siding" to "ahead" when the train is

detected by an IR sensor.

Turtle Point Controller-2 controls a

miniature linear screw actuator to change the point.

The choice of the project will depend on the type of switch you

want to use as well as the space available to operate the set of

points and if you want manual or automatic operation.

Some of these projects use a servo motor and one project uses a very small linear

actuator (called a screw actuator) that responds to the same PWM

signals of a servo.

All these project have been designed to take the place of

expensive controllers on the market and allow

you to make your own controllers.

Go to one of the projects described above for more details.