Save 75 Model

Railway Projects: .doc

(18MB) or .pdf (11MB)

17-4-2023 17-4-2023023023023023023023023023023023023023023023

Our other free

eBooks,

50

- 555 Circuits

1 - 100 Transistor Circuits

and: 101 - 200

Transistor Circuits

100 IC Circuits

Talking

Electronics has produced two books on Model Railway Electronics.

They are

Electronics

for Model Railways-1 (pdf) and

Electronics

for Model Railways-2 (pdf)

These books have completely sold out so we have provided them in .doc format

(Word) and .pdf

All the kits from the two books are still available and we get lots of

orders, but you must make sure

you are good at soldering and see what the module does, before ordering.

Some of the modules are available fully assembled and tested and some have

been improved or simplified

and you need to contact us before ordering anything.

email

Colin Mitchell:

talking@tpg.com.au

Electronics

for Model Railways-1 .pdf

(35MB)

free to download

Electronics

for Model Railways-1 .pdf

(35MB)

free to download

Electronics

for Model Railways-1 .doc

(13MB)

free to download

Electronics

for Model Railways-2 .pdf

(56MB)

free

Electronics

for Model Railways-2 .pdf

(56MB)

free

Electronics

for Model Railways-2 .doc

(13MB)

free

For a

list of every electronic symbol, see:

Circuit Symbols.

For more articles and projects for the hobbyist: see

TALKING

ELECTRONICS WEBSITE

email Colin Mitchell:

talking@tpg.com.au

Talking

Electronics website has more modules and kits

than shown in this index

and the instructions are available

in the two books shown above. As well as

more projects on the website.

New projects and ideas are being added all the time.

|

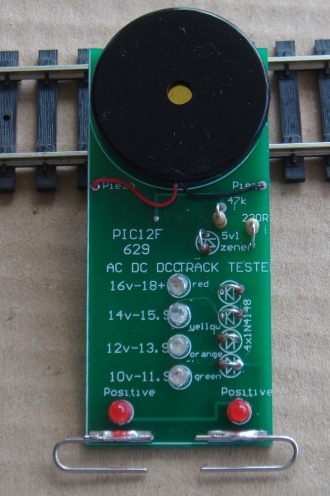

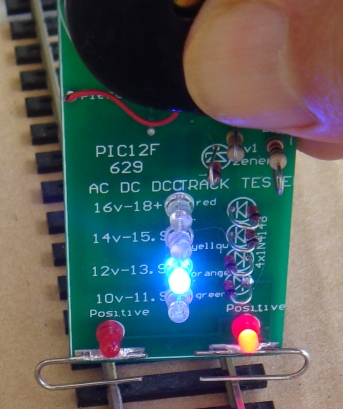

INTRODUCTION If you have

DCC Digital Command Control on your model railway, or are

thinking about using it or starting a layout with this feature, here

is a website dedicated to helping you: Digital

Command Control

is a standard

for a system to operate model railways so that two or more

locomotives can be controlled independently on the same section of

track. |

|

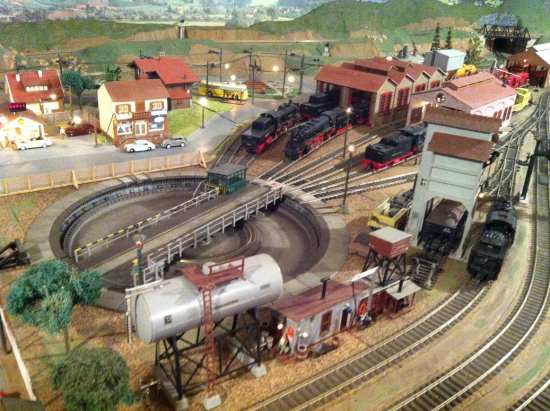

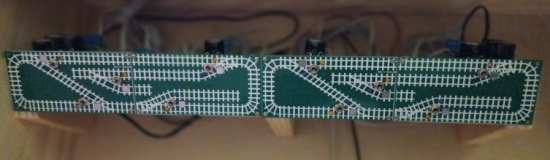

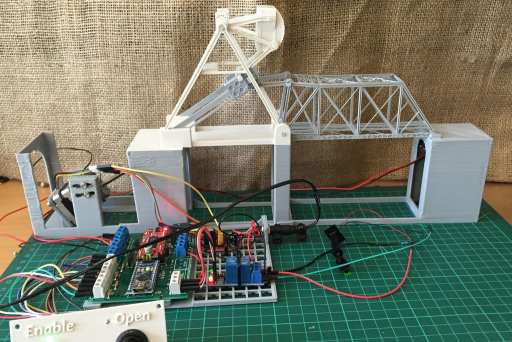

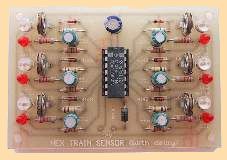

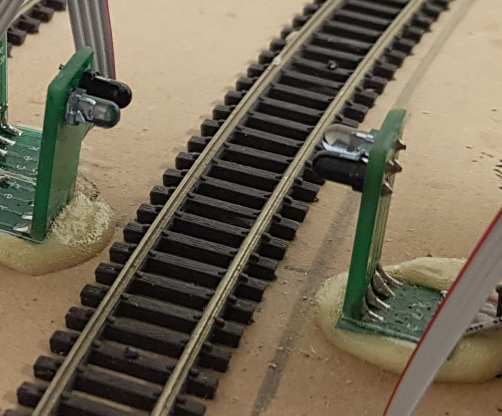

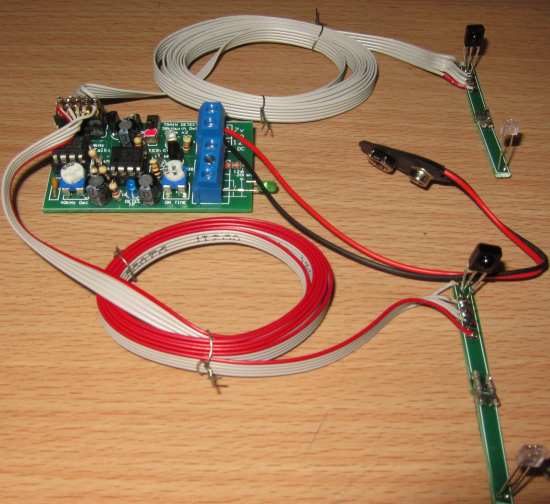

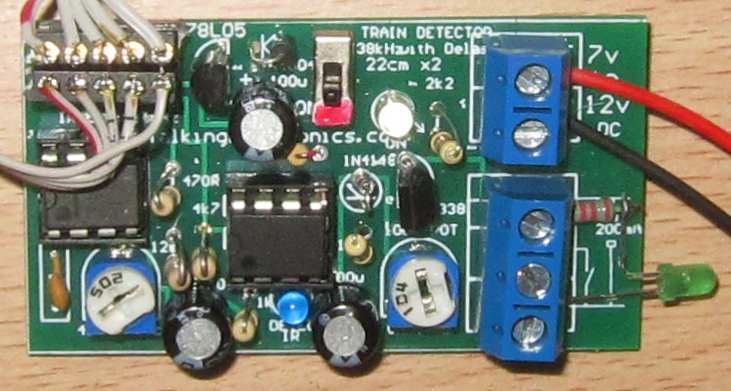

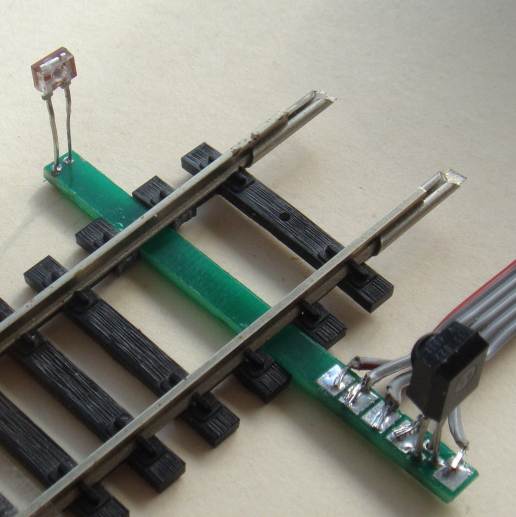

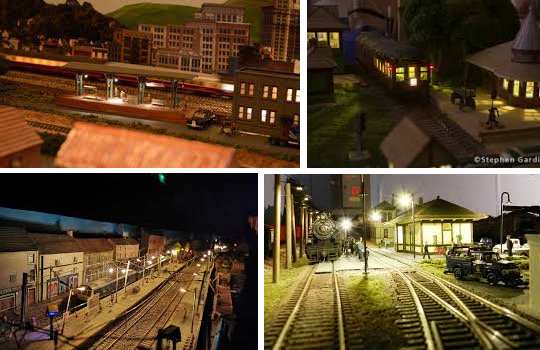

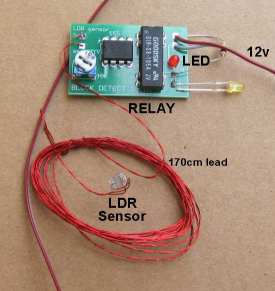

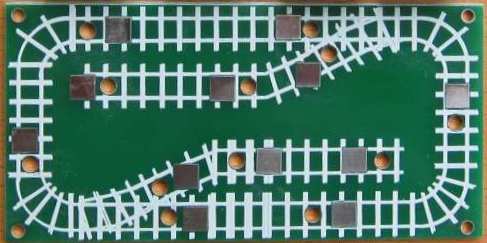

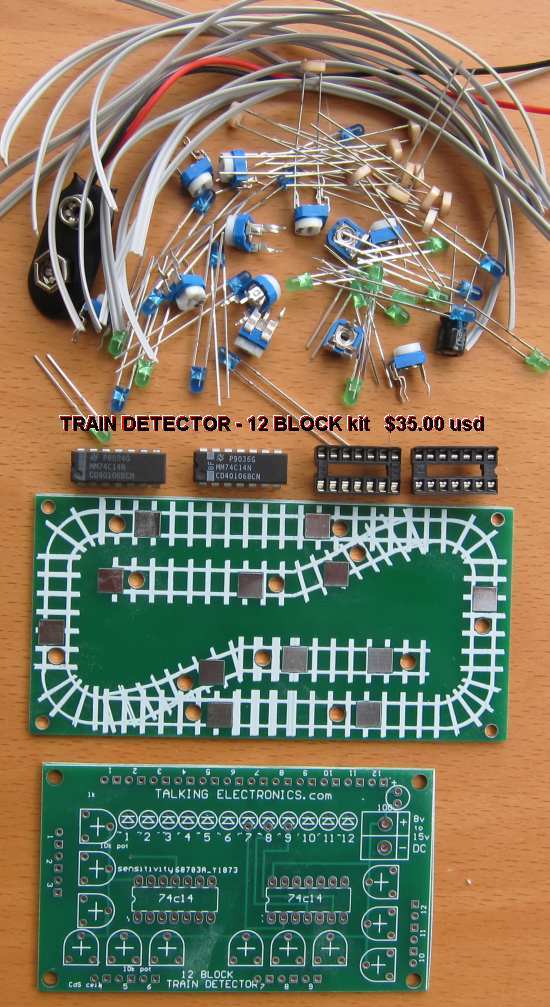

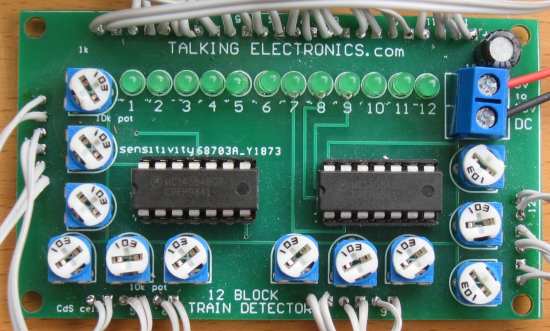

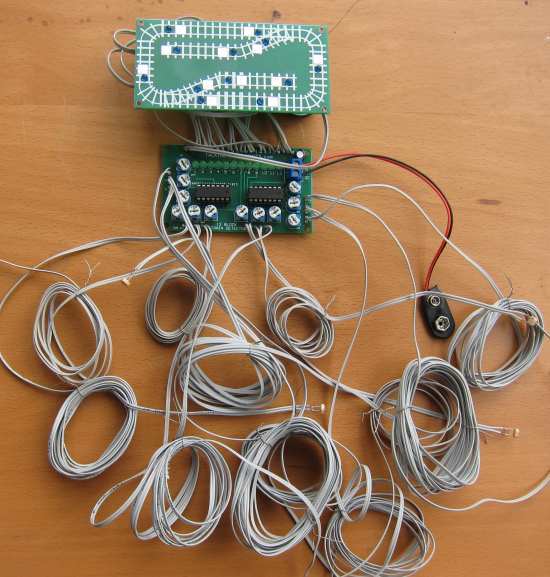

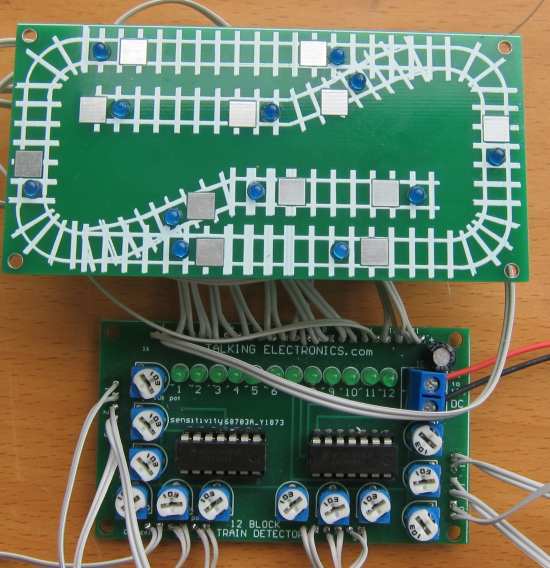

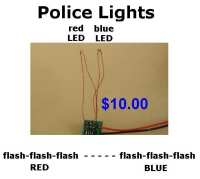

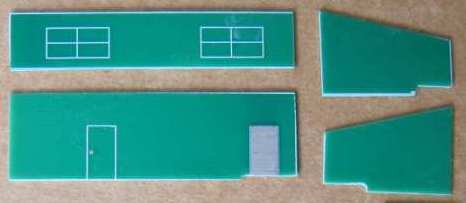

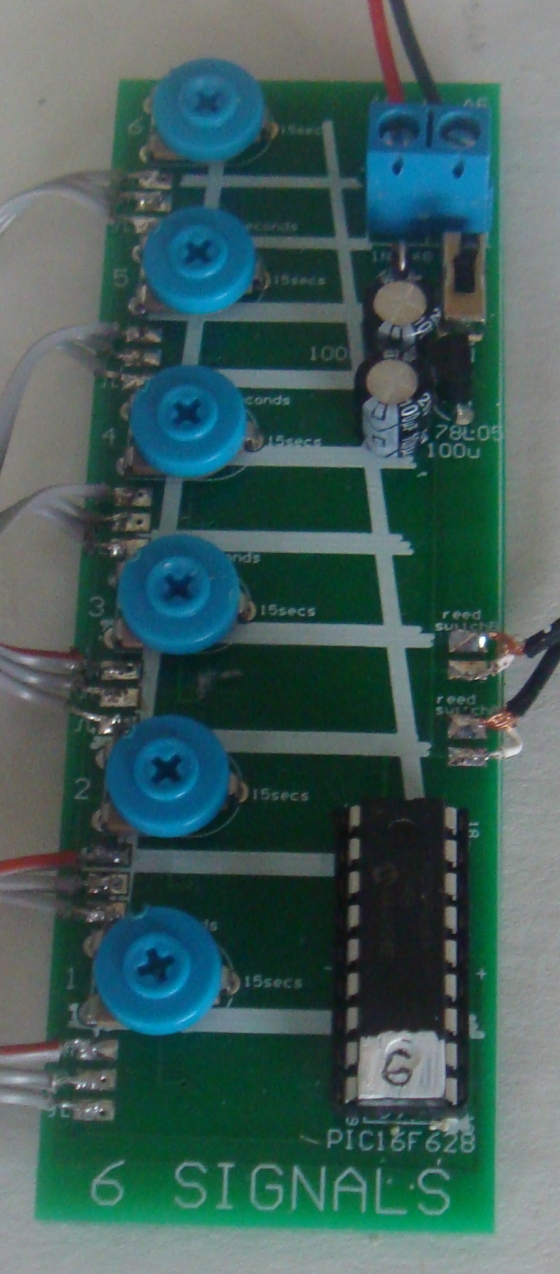

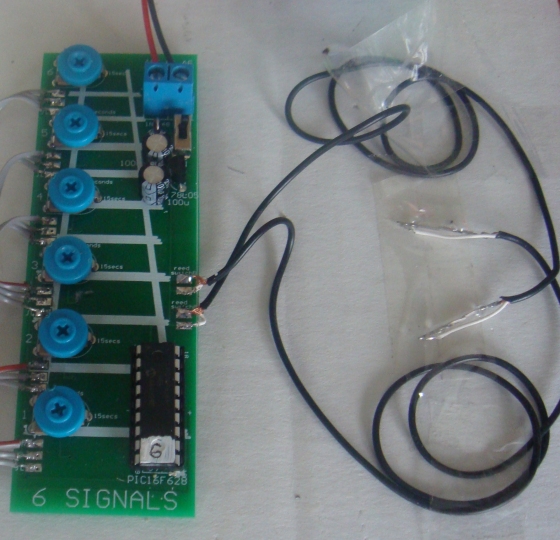

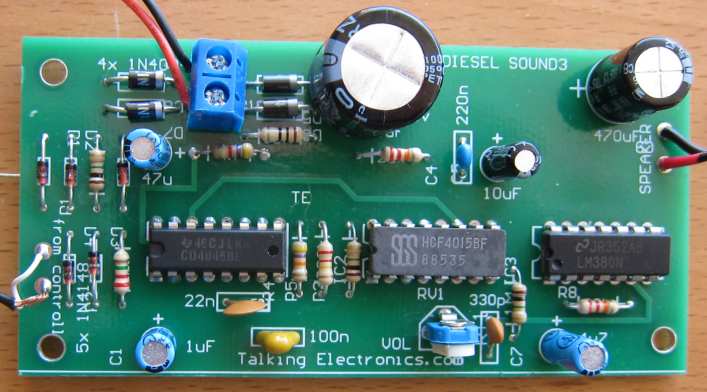

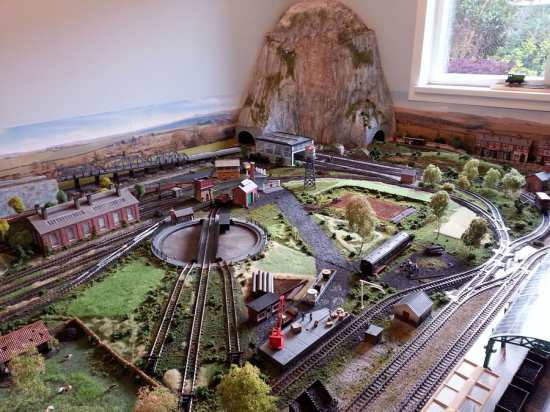

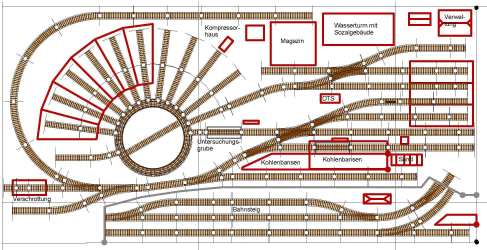

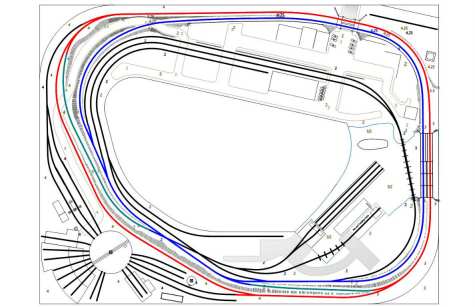

NOTE: Here are 2 of

the latest images: There are 200

more photos of layouts on the website: The next

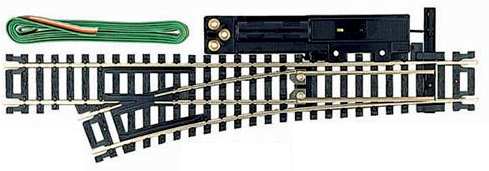

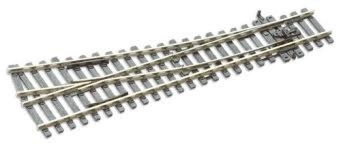

stage is to add points (turn-outs) or cross-overs: |

Every project

needs POWER. Power is ENERGY (actually: Power over a period of TIME

is energy) and it comes from a battery or a POWER SUPPLY.

Power

supplies are also called wall warts, plug packs, chargers or

adaptors and must be of the type that is SAFE. In other words, you

must be able to touch the output wires and the tap in the kitchen

and not get killed.

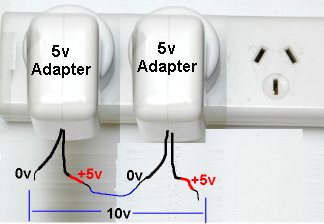

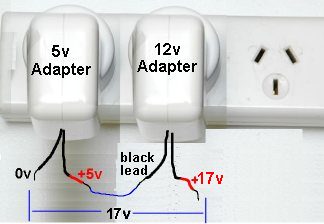

USING DC ADAPTORS IN PARALLEL

Here is a typical 18v power supply for a model railway. This is the ideal supply, but it is expensive and our aim is to show how to produce the same output voltage by using much cheaper items (Plug Packs etc.)

USING AC ADAPTORS IN PARALLEL

USING DC ADAPTORS IN SERIES

You can

connect any TWO or THREE together and the output voltage will be the

sum of all the voltages and the current will be determined by the

lowest current of the 3 adapters. If you do not

have any old Plug Packs, you can buy new ones on eBay for a few

dollars.

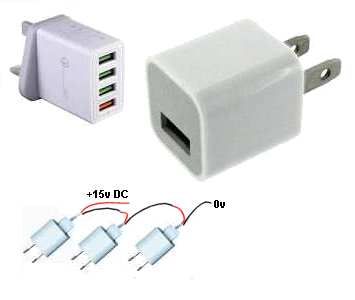

THE BEST ADAPTOR:

The best DC

adapter for all the CDU modules is a 24v or 30v supply made from

two 12v adaptors in series of three 10v adaptors in series.

5v,

10v, 15v POWER SUPPLY

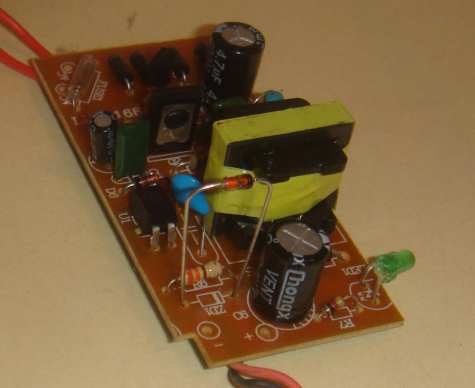

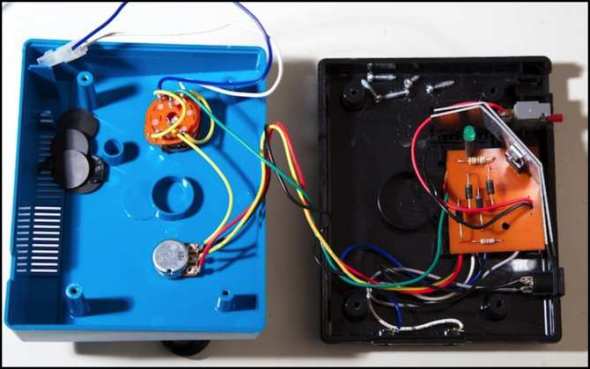

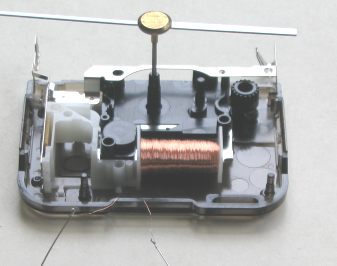

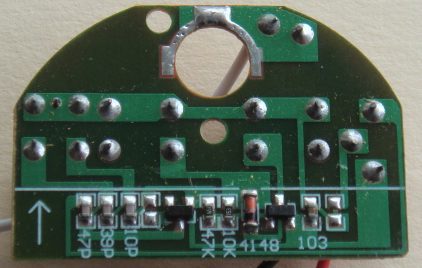

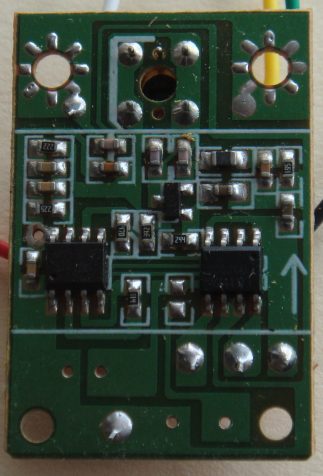

The $2.50 plug Pack above was purchased as 12v @ 1 amp. It was

easily opened-up via a screw and clip, to reveal the PC board shown

below.

36V

!!

THE

ALTERNATIVE TO A WALL WORT Let's look at what we are talking about:

BENCH POWER SUPPLY

They come in all sorts of arrangements and offer current limiting

and output voltages from 0v to 35v (or higher) at 1 amp to 10 Amp

or more.

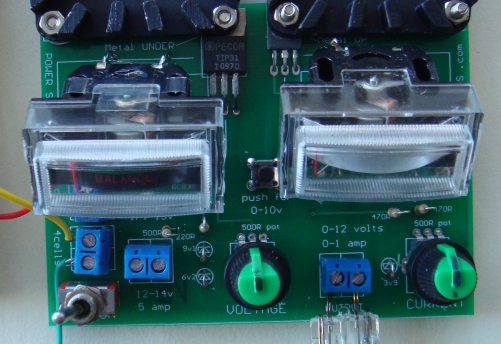

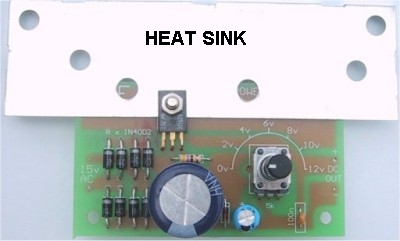

Power Supply MkII

The following project is a 0v to 12v BENCH POWER SUPPLY with

current limiting and has an output of 1 amp. This is sufficient for

all types of testing and you can increase the values by referring to

the circuit.

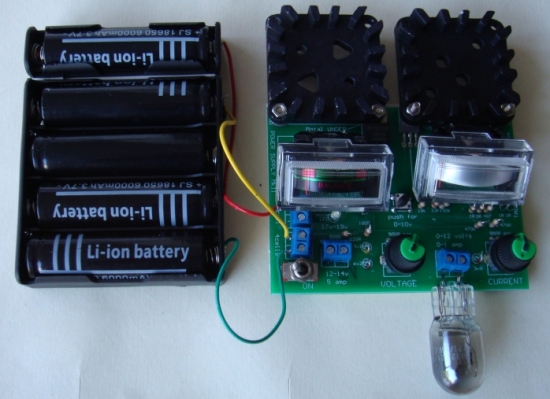

This is the cheapest, safest Power Supply you can get.

Here is a set of 4 Li-ion cells. Just use the 4 lower cells in a 4-cell carrier. The top cell is just to increase the voltage slightly so the project will produce slightly more than 12v at 1 amp.

The 4-cell carrier can be bought on eBay for about $2.50

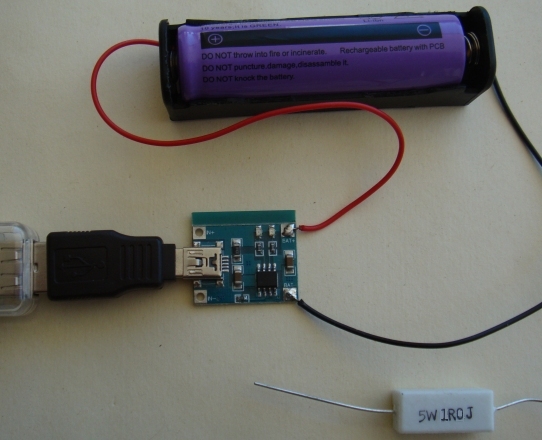

The charger below will charge a single cell at about 500mA to 700mA and connects to your USB port on a laptop. You can only charge one cell at a time with this arrangement.

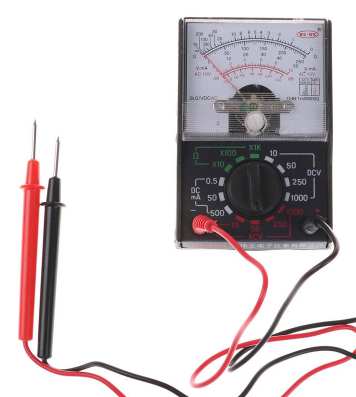

The 1 ohm resistor will discharge the cell quickly. The cell voltage

must not go below a minimum voltage of 2.8v. You need to place a

voltmeter across the resistor while discharging to make sure you do

not discharge the cell below its recommended minimum. The module in

the photo charges the cell quite quickly and at 4.2v the cell is

charged to 90% (or more) and the circuit turns OFF. More details of the project shown above can be found HERE. It describes a 1 amp adjustable POWER SUPPLY that can be used to power your locos or as a BENCH POWER SUPPLY for all your testing.

CURRENT

CONCLUSION ooooooooooooooooooooo0000000000000000000000000oooooooooooooooo

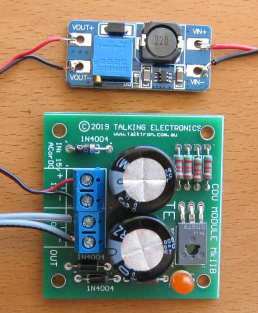

BOOST CONVERTER |

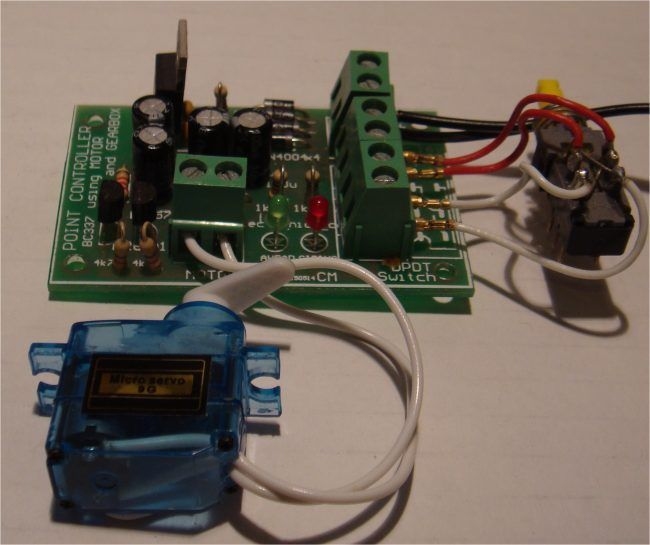

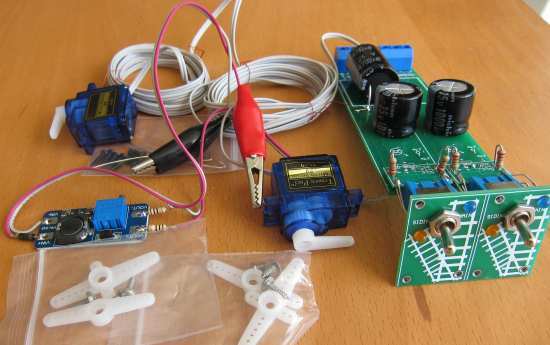

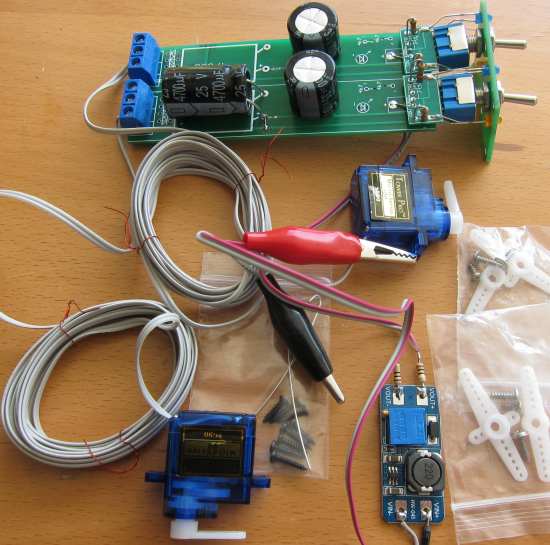

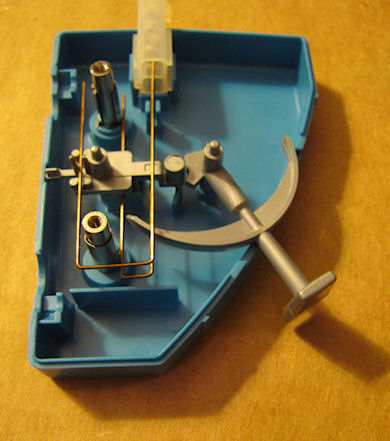

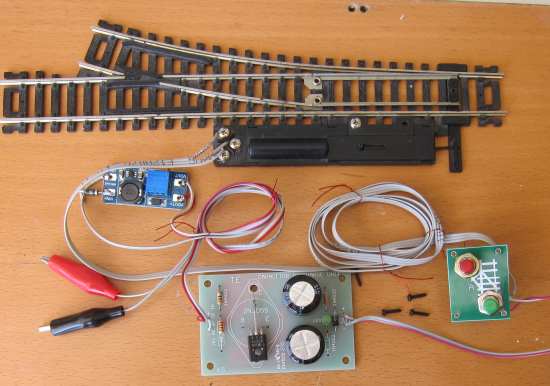

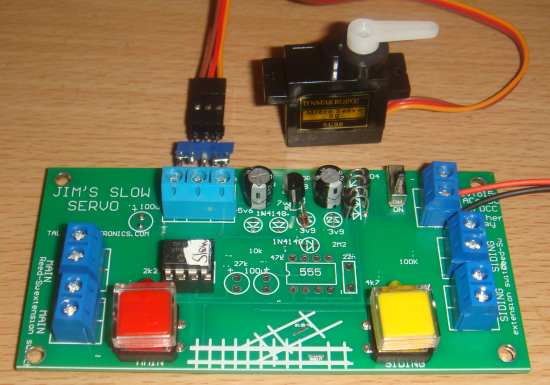

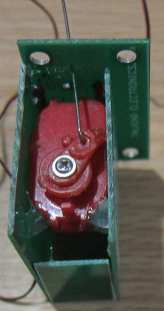

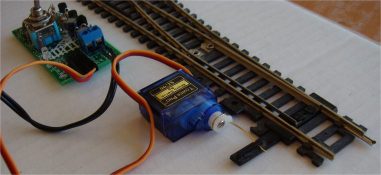

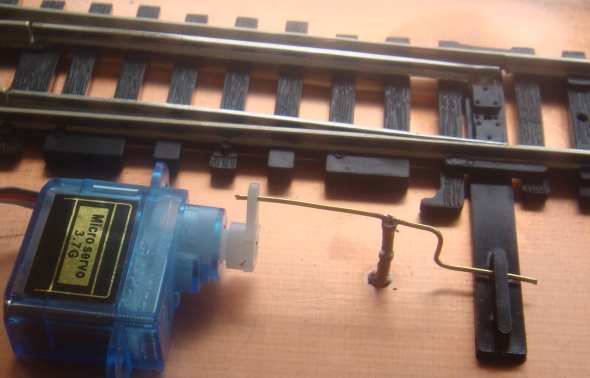

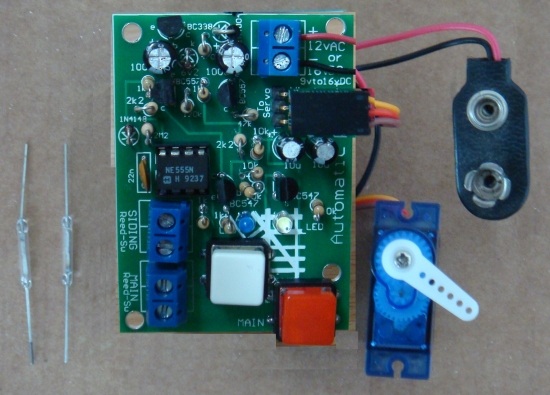

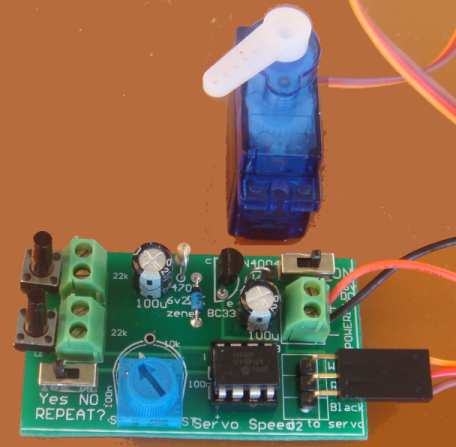

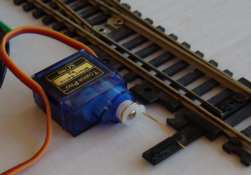

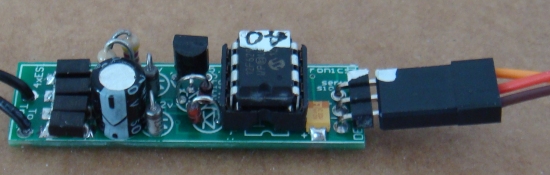

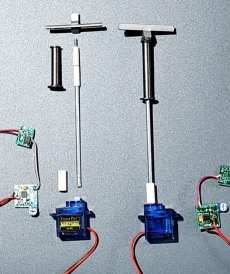

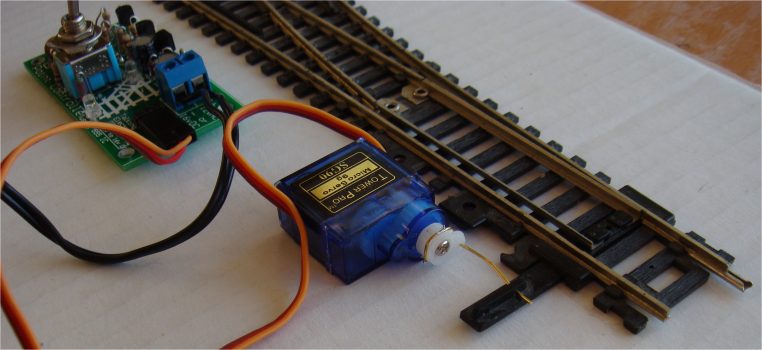

This is PART "A" of our discussion on controlling a point. Talking

electronics has designed and produced a wide range of controllers to

turn a manual point into remote operation. We use a servo to change

the point and not a solenoid. This means nothing will burn out and

the cost will be lower. The servo is also called a motor and gearbox

and the different types will activate the point either slowly or

quickly. You can mount the mechanism either on top of your layout or

underneath.

A

Point Controller is a "device" or "MOTOR" or "SOLENOID" that changes

the point from "ahead" to "Siding."

All layouts need a point

or lots of

points so you can make an impressive layout and have the trains

leave and enter the main line and provide shunting yards and loops

and interconnecting lines.

If you have a

solenoid operated point, we will cover it later:

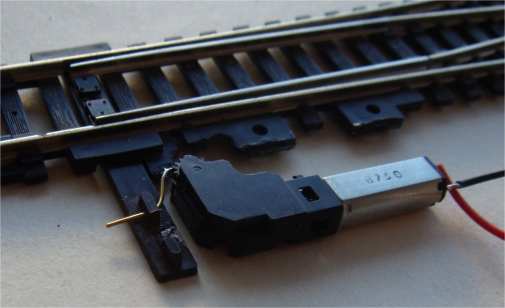

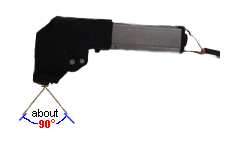

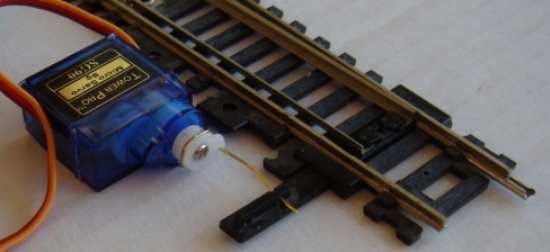

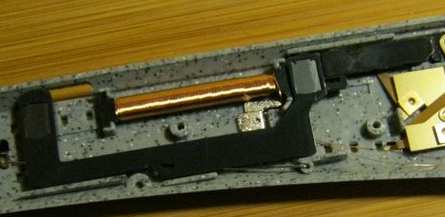

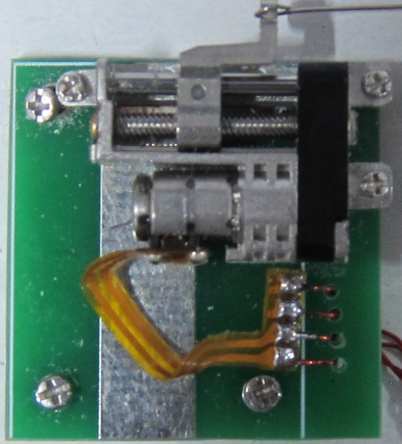

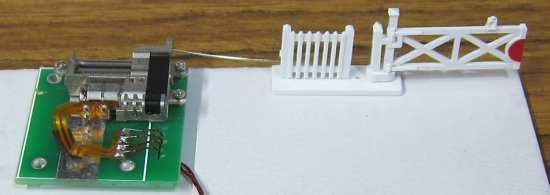

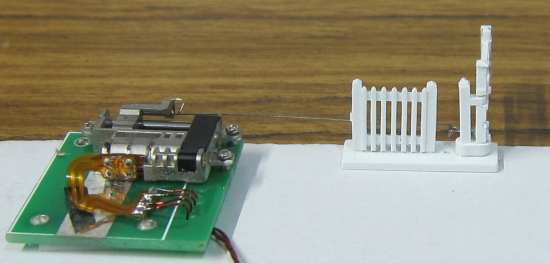

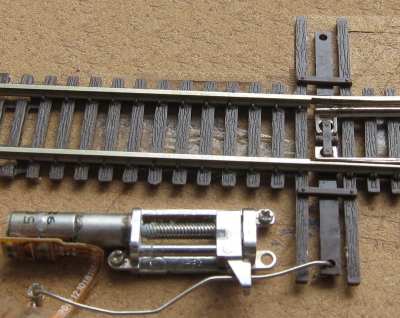

We connect a motor and worm gearbox as shown in the following image to the actuating lever on the point:

Image shows the control rod on the gearbox is

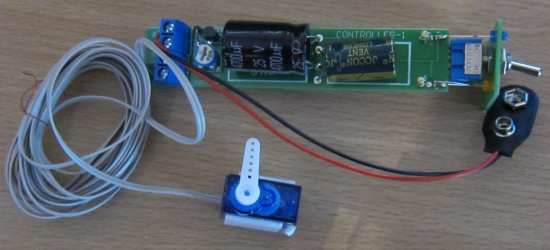

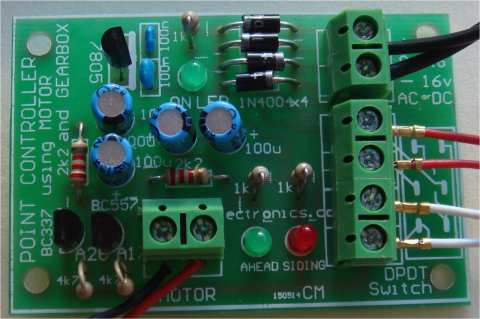

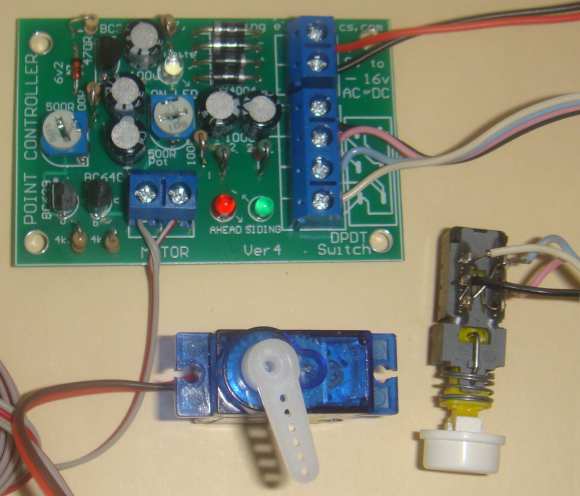

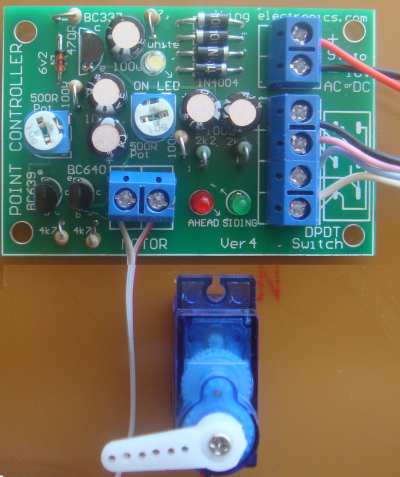

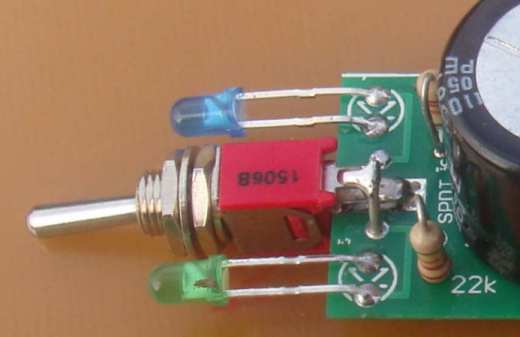

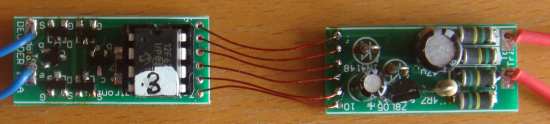

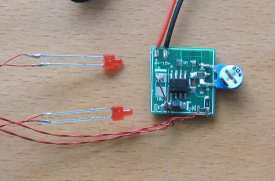

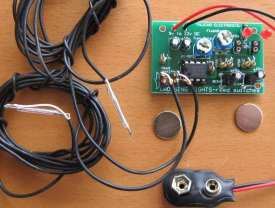

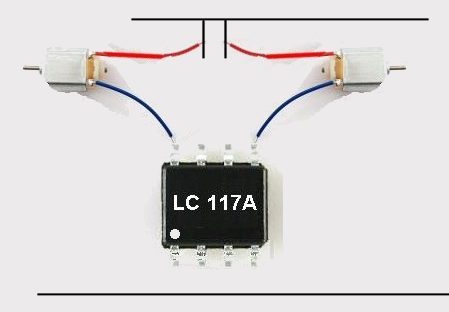

The following image is the module that controls and limits the motor's operation. It allows the motor to be connected to a 9v to 16v AC or DC supply.

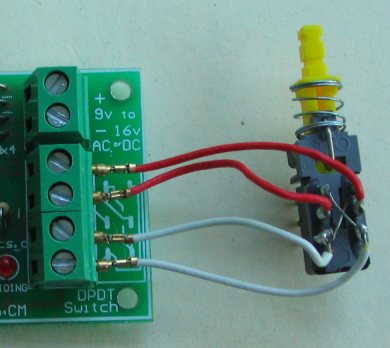

You get a

micro motor with worm gearbox and module and DPDT push-push switch

and the position of the point is shown on the red and green LEDs on

the module. The movement of the point is fairly rapid. There are

other modules with slow movement.

The circuit above uses a 3v micro motor with worm gearbox. The latest PC board has a number of improvements with two 500R pots to adjust the strength of the throw of the arm. oooooooooooooo0000000000000000000000000000ooooooooooooooooo

CHOICE NUMBER 2:

oooooooooooooo0000000000000000000000000000ooooooooooooooooo

CHOICE NUMBER 3: The Printed Circuit Board has 2 x 500R mini trim pots to adjust the amount of travel of the output arm.

oooooooooooooo0000000000000000000000000000ooooooooooooooooo

oooooooooooooo0000000000000000000000000000ooooooooooooooooo

CHOICE NUMBER 5:

Click

Here

to order. oooooooooooooo0000000000000000000000000000oooooooooooooooo

CHOICE NUMBER 6: oooooooooooooo0000000000000000000000000000oooooooooooooooo

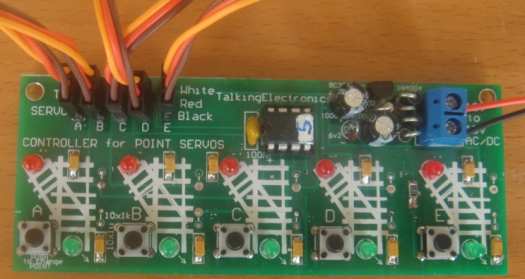

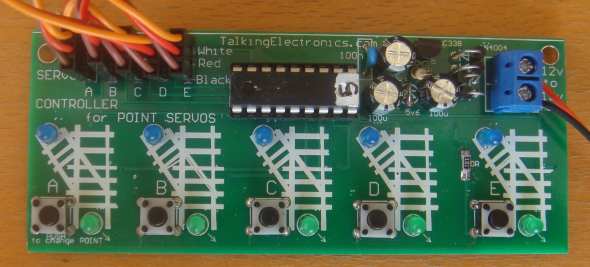

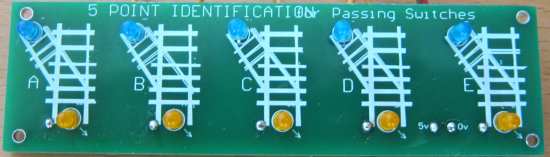

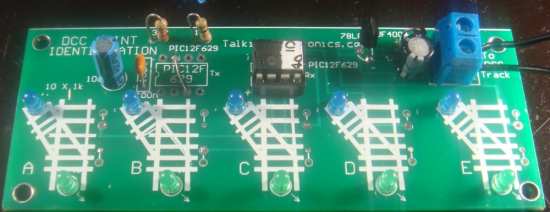

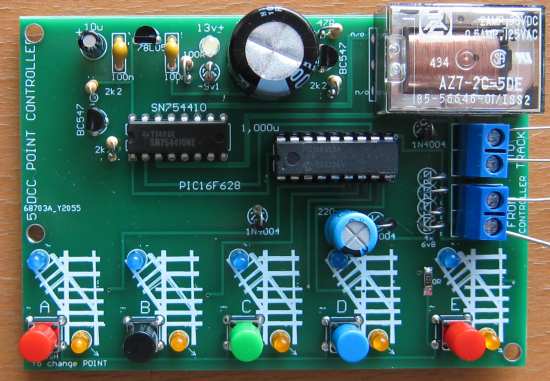

CHOICE NUMBER 7: The on-board tactile buttons need to be pressed for about 1/2 second for the program to recognise the button and activate the servo to set the point to the correct position. You need to set each point so that the PC board reflects the correct position of the point. Do this will all 5 points and you are ready to drive the loco. oooooooooooooo0000000000000000000000000000oooooooooooooooo

CHOICE NUMBER 8:

oooooooooooooo0000000000000000000000000000oooooooooooooooo

CHOICE NUMBER 9: A description of how the circuits works is HERE

CHOICE NUMBER 10:

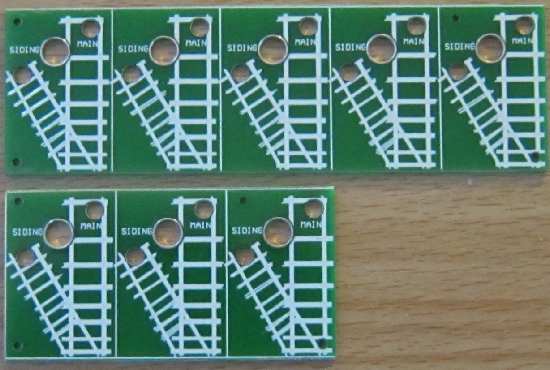

The angular movement of the motor/gearbox is controlled by the

resistors under the PCB and the voltage of the pre-voltage module.

The position of the point is shown by 2 LEDs on the module with an

outline showing the track with siding. This makes it easy to see the

position of the point.

SUMMARY |

|

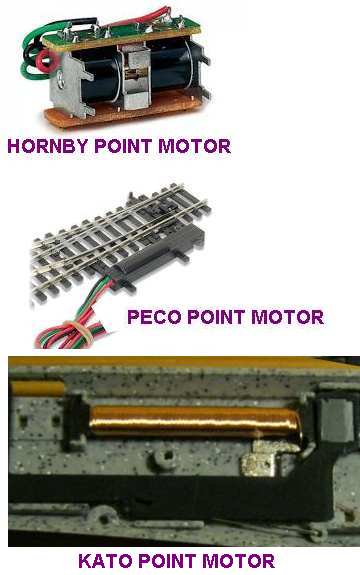

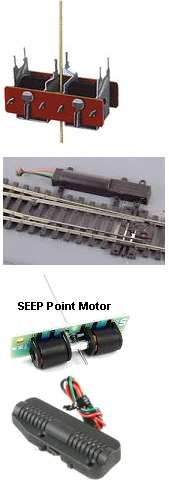

POINT MOTORS oooooooooooooo000000000000000oooooooooooo

KATO SWITCH OPERATES PECO POINT

The switch is simply a double-pole double-throw PASSING SWITCH that

supplies energy to the point at the mid-way of the travel of the

lever. |

Point Motors are also called

Point Controllers or Switch Machines and you

need to be very careful as some of them need control electronics

(which is not included in the price)

while others are just an empty box. Blue Point

Switch Machine

$14.00 usd

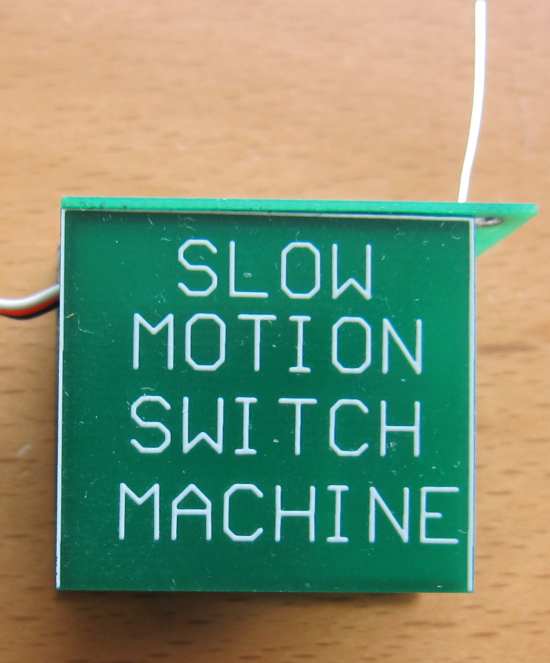

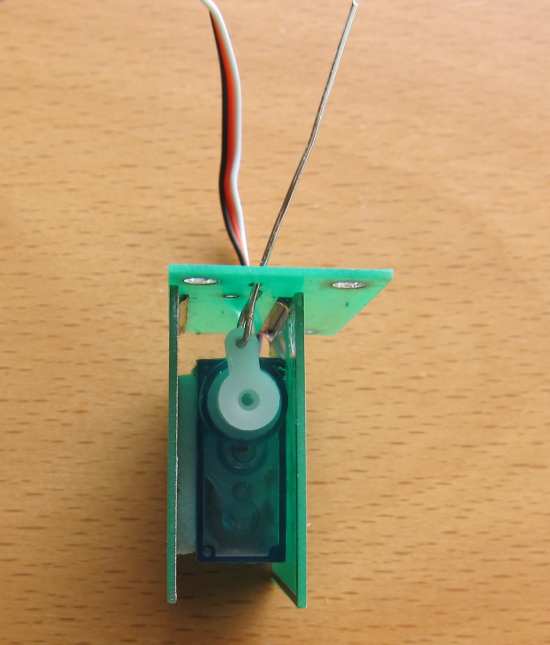

Turtle Slow Motion Switch Machine $10.00 usd

The Turtle Slow Motion Switch Machine is

fitted under your layout and requires an electronics module

to provide slow activation for the servo. The module

will activate 5 Slow Motion Switch Machines and costs $25.00 usd plus

$10.00 for five 2metre extension leads.

Tortoise Slow Motion Switch Machine $35.00 usd

Motor stalls at each end of throw

Turtle Fast Switch Machine

COBALT

Analogue $35.00usd You can choose the Slow

Motion or Fast Action Turtle Switch Machines from Talking

Electronics for less than 50% of the cost of the devices

on the left.

Slow

Motion and Fast Action Turtle Switch Machines do

not have switches or relays or extra contacts and are simple

to connect to your Control Panel with 2 or 3-core

lead.

A 2-core extension lead (2metres long)

costs $2.00 extra. |

|||||||||||||||||||||||||||||

This is PART "B" of our discussion on controlling a point.

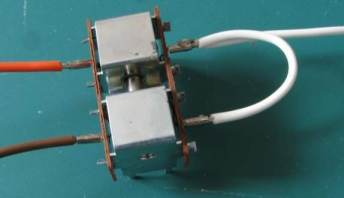

The SOLENOID Point Motor consists of two coils of wire that

alternately pull a metal rod into the middle of the solenoid and at

the same time change the position of the point.

oooooooooooooo0000000000000000000000000000oooooooooooooooo

CHOICE NUMBER 8:

-

see the new version (dual) for $18.00

The screw terminals make it easy to fit to your layout.

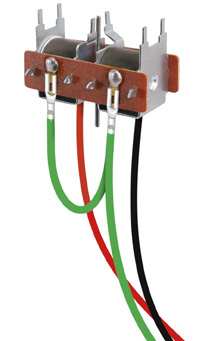

The green

wire is called the COMMON

The PL-26 switch is called a PECO PASSING SWITCH because it

only makes contact when the lever is just before or just after the

top position. This means it is not making contact when fully left or

fully right.

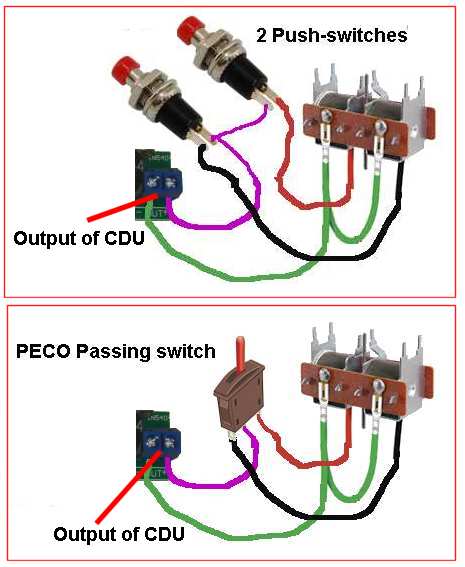

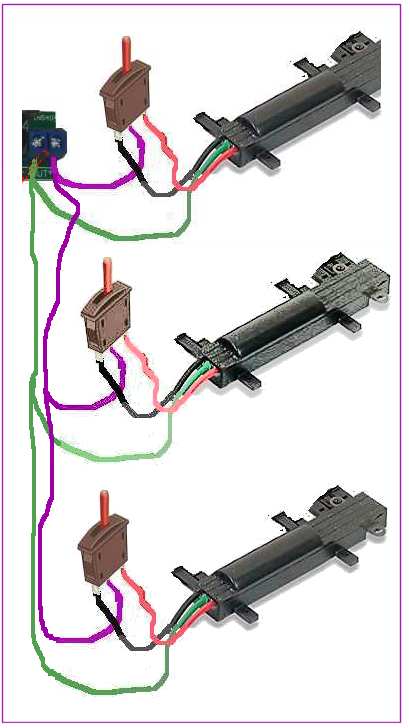

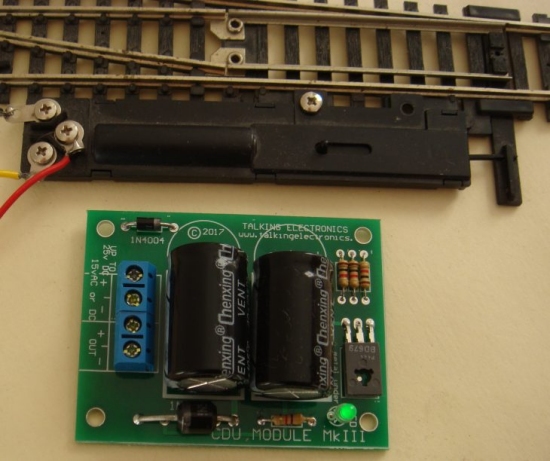

Our CDU module fits between the Power Supply and the switch or

switches to a SOLENOID POINT MOTOR. It is designed to deliver

a short pulse of energy to the solenoid to change the position of

the point. A Passing Switch will deliver a pulse of energy

but if it gets stuck in the mid-position, our CDU will prevent the

point motor "burning out."

PASSING SWITCH -

for Point Motors

The PECO Passing Switch (shown above) is a very bad

design as it does not deliver the energy to the point CORRECTLY when

the lever is moved from one side to the other.

There are two more

switches that can be used to control a solenoid point.

CAPACITOR DISCHARGE UNIT MkII - MODIFICATION

Universal EU US Plug Switching Adapter AC 220V-240V To 5 V 12 V 24V

Volt Power Supply DC 5V 12V 24V 1A 2A 3A 5A Power Adapter

Output Voltage 24v US Plug Current 1A $3.60

CDU MKIIB shown above is no longer available. It has been upgraded.

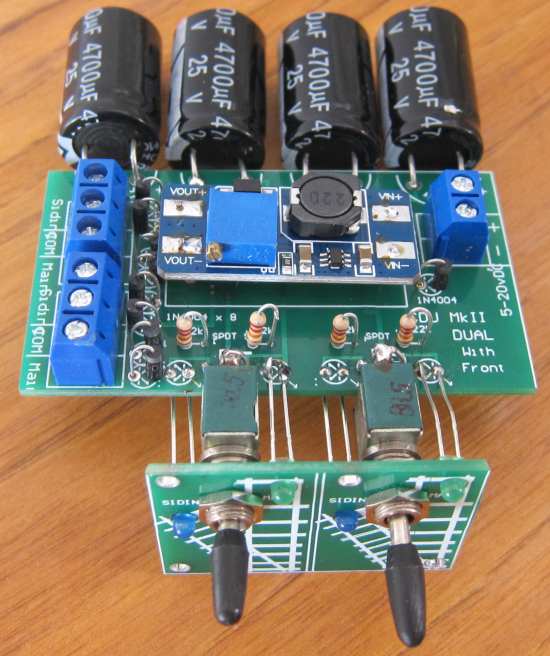

The new CDU MKIIB module comes with a pre-voltage module and push

switches with front panel.

This Capacitor Discharge Unit is easy to connect to your layout with

screw terminals. ooooooooooooo0000000000000000000000000000oooooooooooooooop>

CHOICE NUMBER 8A:

oooooooooooooo0000000000000000000000000000oooooooooooooooo

CHOICE NUMBER 8B: FOR 2-KATO POINTS

To operate a KATO

point connect the two outer screw terminals together

CHOICE NUMBER 9:

The amount of energy delivered to the solenoid depends on the

voltage delivered to the module. For 12v DC supply, the solenoid

will work very delicately and will be suitable for small solenoids

used in "Z-scale." Supplying 16v AC will deliver FOUR times more

energy and will be suitable for larger scales and can operate 2

points. oooooooooooooo0000000000000000000000000000oooooooooooooooo CHOICE NUMBER 10:

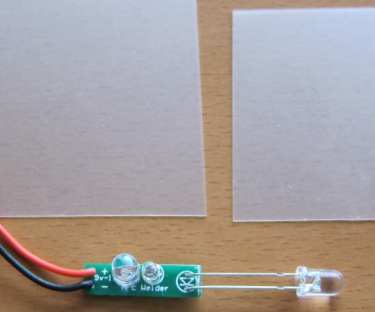

Talking Electronics has an In-line version that takes up less

space on your console. This In-line CDU module has two LEDs

that show the position of the point. It is fitted to your control

panel and the LEDs show the position of a point. This very handy for

a point that cannot be seen from the control area.

The input voltage needs to be 12v to 16v AC or DC and you may need two adaptors in series to get this voltage. See Chapter 1 for the Plug Packs (or Choice Number 11). oooooooooooooo0000000000000000000000000000oooooooooooooooo

CHOICE NUMBER 11:

You can use the "accessories" output of a train transformer if it is

DC (14v DC to 24v DC) or if the accessories output is AC (14v AC to

18v AC). The module has been tested up to 20v AC but it is best to

keep to 18v AC max.

This principle applies to all CDU's. It does limit the "inrush current" and you can email me if you are adding a VOLTAGE DIVIDER to another project to see if any reduction in operation will occur. oooooooooooooo0000000000000000000000000000oooooooooooooooo

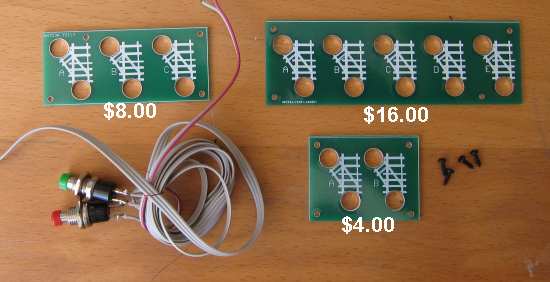

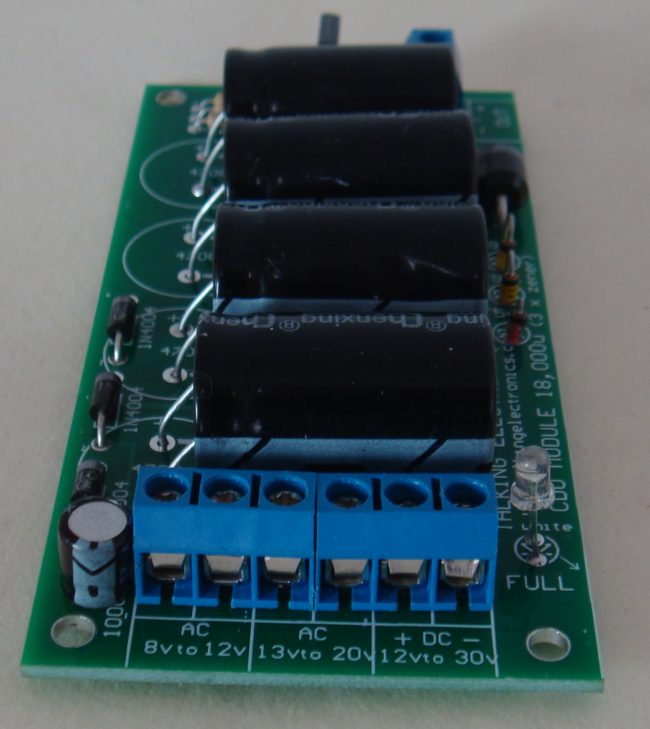

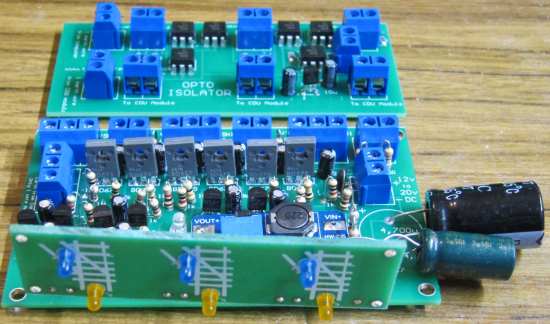

A

larger CDU is also available from Talking Electronics, to change up

to 8 points at the same time:

This Capacitor Discharge Unit is easy to connect to your layout

with screw terminals. A Switch Module can be fitted to this CDU to activate the solenoid point and also show the position of the point via two LEDs:

The SWITCH MODULE (shown in the images above) connects to 18,000u

CDU for $7.00 extra. oooooooooooooo0000000000000000000000000000ooooooooooooooooo

CHOICE NUMBER 13:

oooooooooooooo0000000000000000000000000000oooooooooooooooo

CHOICE NUMBER 14:

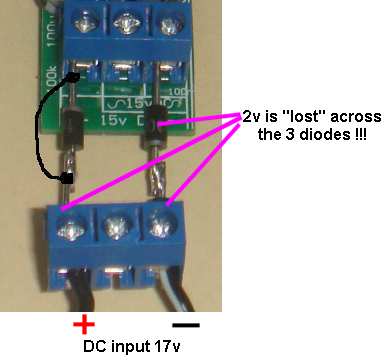

The VOLTAGE REDUCER MODULE consists of a 3-terminal block and

4 power diodes and screws into the 3-terminal block on the module.

If the input voltage is 17v, you can remove one of the diodes by soldering a link across one of the diodes (to short it out), as shown in the following image:

If the input voltage is 16v you can remove 2 diodes and if it is 15v, you do not need the VOLTAGE REDUCER MODULE. If you want to deliver 15.5v DC to CDU 18,000u Slimline - MkII with two plug packs, here is the circuit:

A Switch Module can be fitted to this CDU to activate the solenoid point and also show the position of the point via two LEDs:

The SWITCH MODULE (shown in the images above) connects to 18,000u

SLIMLINE CDU for $7.00 extra. oooooooooooooo0000000000000000000000000000oooooooooooooooo

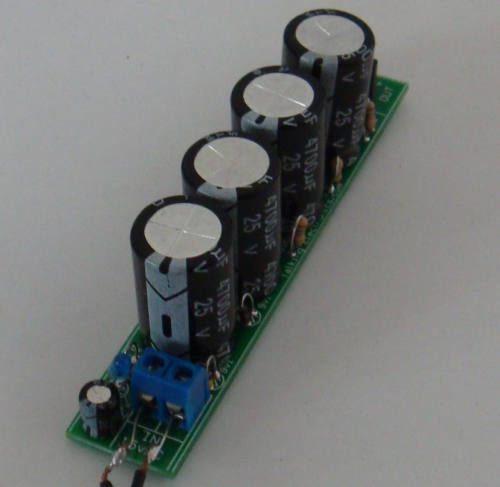

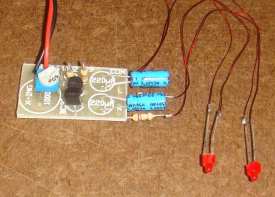

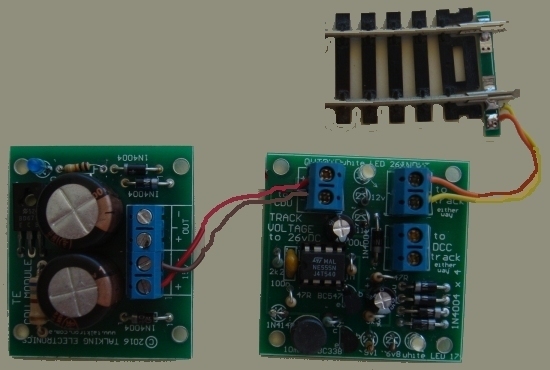

PRE-VOLTAGE MODULE $5.50

The name: Capacitor Discharge Unit with SPDT Switch - SLIM

has been chosen to identify it from all the other CDU modules made

by Talking Electronics.

All the components fit on the PC board and the module comes with 2 x 1,000u electrolytics. The input can be 12vAC to 15vAC or 20vDC to 35vDC.

You can make a 12v 24v or 36v supply very cheaply by using 24v and

12v plug packs. These are available on eBay for less than $10.00

(combined) including postage.

Using an old Printer Power Supply

There are lots of other power supplies from discarded electronic equipment and you just have check everything before you throw it out.

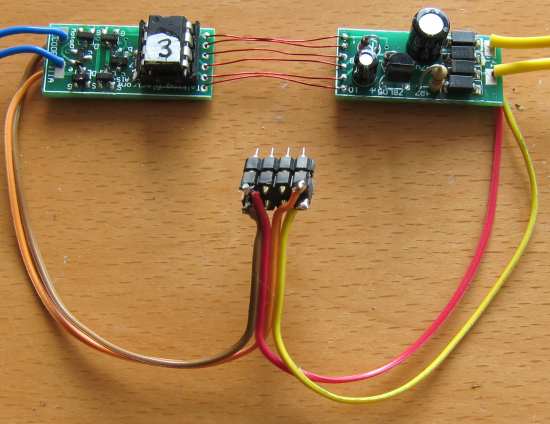

2

MODULES

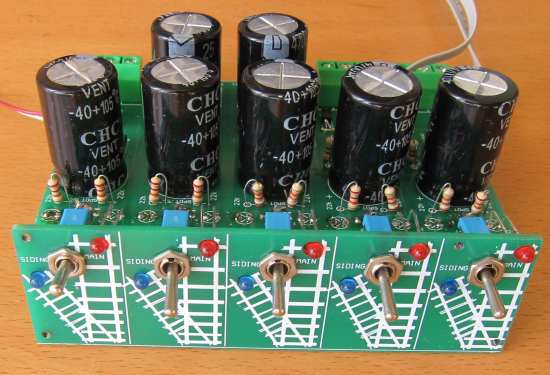

ooooooooooooooooooo000000000000000000000ooooooooooooo 5 MODULES

CDU with output for 2-Aspect signals:

This module comes with a pre-voltage module to make things easy for

you. You just need a supply of 9v to 20v DC and the pre-voltage

module will output 25.5v to the CDU modules.

You can mount 2 or 5 modules "side-by-side" and use the face-plate

shown in the photo below to connect them together and fit them to

your console.

The circuit for the 5-Modules version has 2 x 4,700u electrolytics

in the power supply section because the charging of the 2,200u (in

the second part of the circuit shown above), when the switch is in

the "MAIN" position, will take a lot of energy from the 4,700u in

the power supply and the voltage across it will dip 50%

(theoretically). When 5 modules are connected to the power supply,

this will be passed to the other modules and affect the operation of

the other points at a time when they should not be affected.

This CDU (Capacitor Discharge Unit) module has been designed with

voltage-doubling components so you can use the 12v DC or 15v AC

terminals of your train power supply. It also has voltage regulating

to prevent over-charging the electrolytic and an indicator LED to

show when the electrolytic is fully charged.

This CDU has improvements and now replaces some of the older designs as it operates better at low voltage and provides equal thrust in both directions.

This project combines a number of features from three of the

projects we have previously designed for Model Railway Hobbyists.

It is available as a kit or fully built and tested.

THE

CIRCUIT |

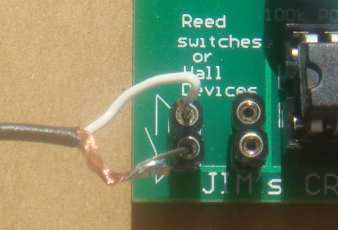

JIM's CDU MkII circuit

|

SOLDERING THE KIT

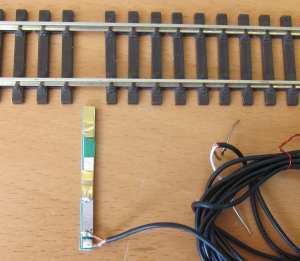

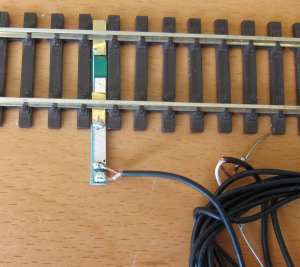

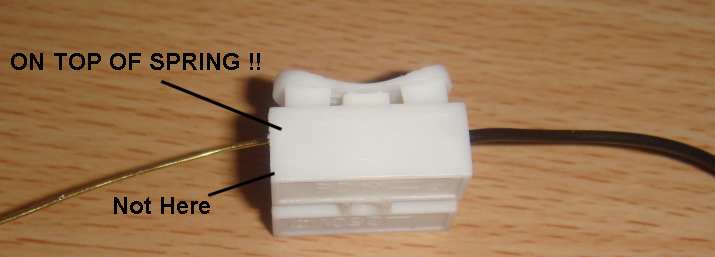

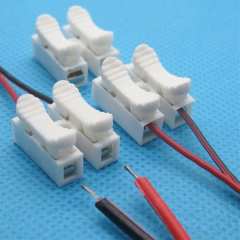

Alternatively, you can ask for Track Pick-off "using Rail Joiners." You will need to get to the track, remove the rail joiners that presently connect the rails, and fit the track jointers as shown in the following image:

CONCLUSION oooooooooooo000000000000000000oooooooooooooo

CHOICE NUMBER 18:

The original circuit used two 555 IC's. The new and improved circuit

uses a microcontroller and 15 fewer components !! That's why some

of the components are no longer required.

CHOICE NUMBER 19:

The SLOW MOTION SWITCH MACHINE costs $8.50 usd and comes with 2

metre of 3-core lead.

This is the latest Slow Motion Switch Machine using digital control

to the motor.

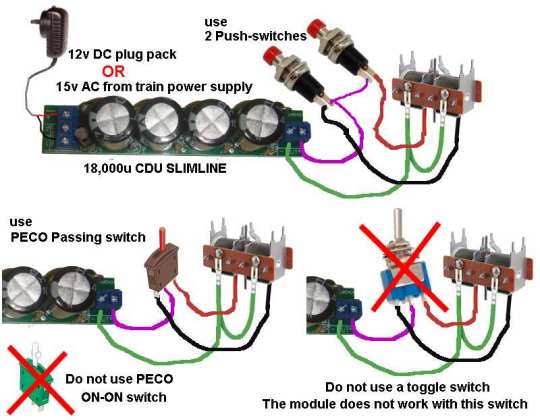

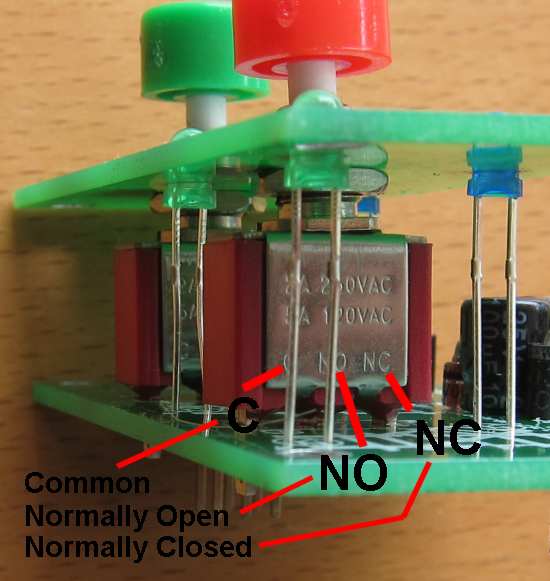

The switch MUST be fitted so the letters "C" "NO" and "NC" can be

seen as per the image above. They will not work if fitted the wrong

way around. These are special switches - push switches - and not

toggle switches. Push the legs through the holes of the printed

circuit board and before you solder the pins, try the operation of

the module. When you know it operates correctly, solder the pins

with the fine solder provided. |

|

TURTLE - 2 POINTS CIRCUIT All the work

is done by the microcontroller. |

|

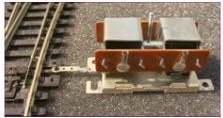

PECO PL1000 TWIST LOCK POINT MOTOR The PECO Twist

Lock Point Motor is a double-acting solenoid and is not really a

"motor" in the sense of the word. A motor has a revolving

output shaft and does not "click" or "vibrate" or "pulse."

The PL1000 is placed

under the layout and it has a resistance of about 3 to 6 ohms, so

the current it will take from a 12v supply will be 2 to 3 amps. It

must be activated for a very short period of time, otherwise it will

get hot and melt the plastic. |

|

CHOICE NUMBER 20: Point Controller for 1 Motor/Gearbox $18.00 see also for 2 Motor/gearboxes and 4-Motor/gearboxes   Convert your manual point into a remote point with this motor/gearbox activator using the push-rod supplied. The module has a front panel showing the position of the point and operates from a 12v supply. The on-board mini trim pot adjusts the "throw" of the push rod to suit mounting on your layout or under the layout. A bracket for mounting the gearbox under your layout is also available. This is the cheapest way to convert points to remote operation. Buy Point Controller using Motor/Gearbox $18.00 plus $8.50 post |

|

CHOICE NUMBER 21:

Buy 5 Point Controller for Servos $25.00usd plus $6.50usd post |

|

CHOICE NUMBER 22:

|

|

|||||||||||

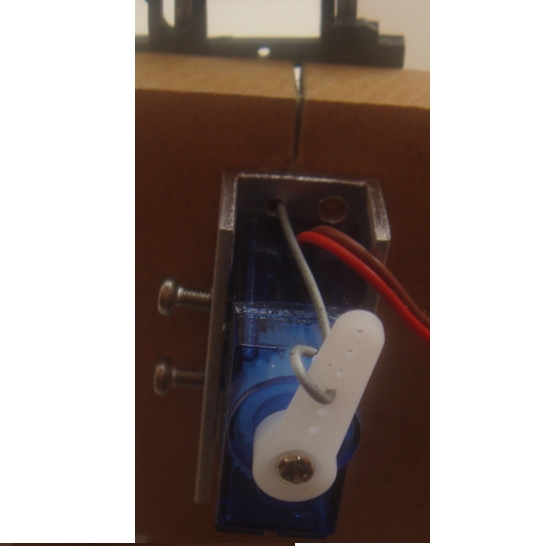

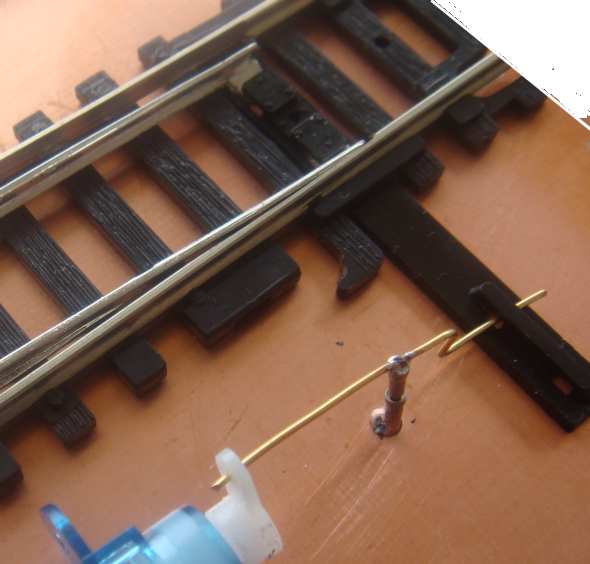

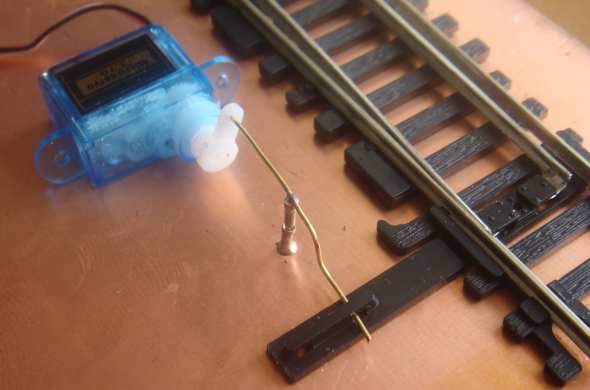

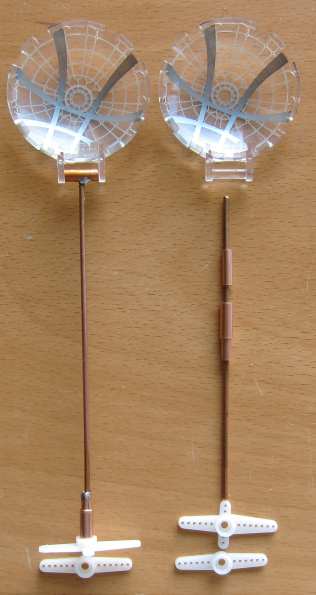

The image on the left is just an example to show the connection of the servo to the point. The servo can lay down to take up less room.

There are

many ways to connect the servo to the "switching lever" and here's

one way that adjusts the movement of the arm on the servo to the

travel needed by the switching lever. The following images clearly show how the 3.7g SERVO is connected to the point via a LINKAGE:

THE

SUPPLY

SETTING-UP THE MAGNETS

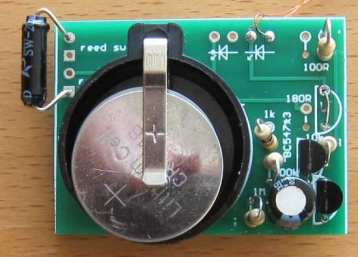

FITTING the REED SWITCHES

----------------------oooooo000000oooooo--------------------------

Automatic Point Switcher

is available from: This is

another Automatic Point Controller from Talking Electronics

to cover slightly different requirements.

oooooooooooo00000000000000oooooooooooo

This module changes the point automatically and has 3 other

features so you can design a layout with a loop.

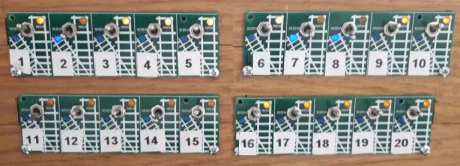

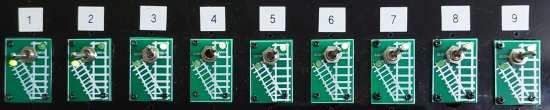

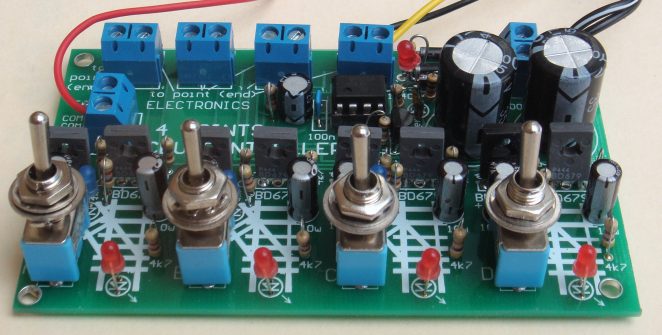

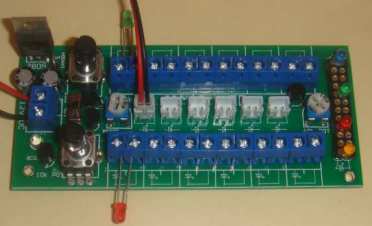

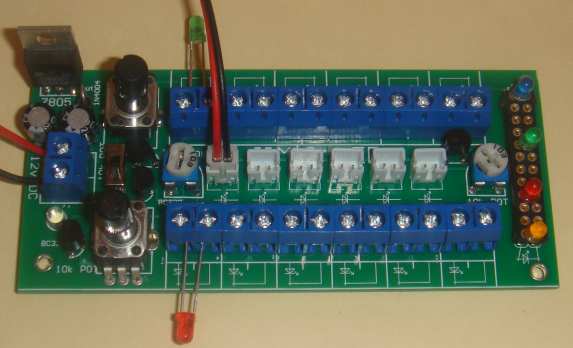

4 Points CDU Controller

This module will change the position of 4 point

motors via the 4 toggle switches and the LEDs on the

board show the position of the point. The module

comes with the switches separate in a plastic bag

because they are too tall to post in out small

posting box. You can solder the switches to the

board or fir them to your control panel and use

3-core ribbon cable. The two outer wires of each

point are connected to the 2-terminals above and the

4 middle wires of the points connect to the

2-terminal block on the left of the module.

The circuit has been included so you know how it connects to the solenoid points. The oscillator circuit using the 555 increases the input voltage to 25v. It is fully built and tested for $35.00 usd plus $8.50 usd postage Please log into your paypal account and send a payment to talking@tpg.com.au for $43.50 usd oooooooooooo000000000000000000oooooooooooooo

CHOICE NUMBER 26:

This module controls 4 Kato points.

The

CIRCUIT

Understanding KATO The KATO Throttle is called KATO POWER PACK

A Kato 22-018 Power Pack is available on eBay for $40.00 shipped and you will need an AC plug pack The KATO 12v AC plug pack costs $25.00 to $40.00 on eBay BUT is for 100v AC and is not much use in the rest of the world. The advertisers don't tell you it's for 100v AC. There is NO 240v version.

What you need is a transformer as shown above. It converts 240v AC

to 12v (or 15v) at about 1 amp. Now we come to adding a KATO TURNOUT CONTROL SWITCH. The photo below shows 5 switches added to a KATO Power Pack.

These switches have two studs on each side and they click into the studs on the right-hand-side of the Power Pack. The two terminals called 0v and 12v on the circuit above are the studs and are not 12v (as explained above) but possibly about 14v pulsed DC.

The KATO 24-840 Turnout Control Switch (shown above) is

actually a PASSING SWITCH and only makes contact when the lever is a

little-bit down from the top and a little bit up from the bottom.

These switches cost about $8.00 on eBay.

If you don't have a KATO POWER PACK, you can buy a Kato 24-829 Accessory Adapter. It is also called Kato 24-842 DC Converter. It contains 4 diodes and converts an AC voltage to PULSED DC. The Passing Switches will then send the pulsing DC "around one way" to the point via a pulse or "around the other way" via a pulse. Here is a Kato 24-829 Accessory Adapter clicked onto two KATO 24-840 Turnout Control Switches.

You can see the DC Converter has click fittings on both sides If you have 15v AC from a "TRAIN TRANSFORMER," you can connect the 15v to the two wires coming from the back of the Kato 24-829 Accessory Adapter. If you have 12v DC, you can connect to the two wires (around either way) but the output will be 10.5v DC. This will be sufficient to pulse the KATO POINT MOTORS (solenoids).

Talking Electronics has designed a number of modules to replace KATO modules.

This module

controls 1 Servo. The following images show different servo

brackets available on the web and nearly all of them require a

limited angular movement. Normally a servo rotates about 270 degrees

but the bracket requires less than 45 degrees.

You just need 9v to 12v DC to operate

the module.

changing when the points are changed. In most cases you only need one micro-switch to change the polarity of the frog. The servo moves very slowly by controlling the pulses to the electronics inside the servo.

Servo Brackets are available for $2.50 usd. You must specify if you want above layout bracket or Under layout bracket.

Talking Electronics bracket for under layout

This bracket comes in 2 versions. One version can be

mounted above and the other below the track.

The control wire for "Under Layout"

bracket is very thin spring steel and the activation is designed

to "overshoot" and allow the spring in the wire to hold the rail

in position.

Buy Point Controller using Motor/Gearbox $18.00 plus $8.50 post oooooooooooooooooo0000000000000000000oooooooooooooooo

CHOICE NUMBER 30:

POINT CONTROLLER

The project comes complete and fully wired with 2 converted servos on two metres of twin lead. The front panel shows the position of each point via LEDs and the toggle switches select the position of each point. The position of the point is shown by 2 LEDs on the module with an outline showing the track with siding. This makes it easy to see the position of the point. The converted servos only travel 90 degrees or less and you can adjust the travel by altering the output voltage of the Automatic pre-voltage module. This module needs a supply from 9v to 20v and it outputs a constant voltage, set by the 10-turn pot on the module. To reduce the voltage, turn the screw a very small amount clockwise. You can measure the output voltage with a meter as the adjustment is very sensitive. The converted servos are called a MOTOR AND GEARBOX and come with a spring-steel "push-rods" that also acts as a lever when you are fitting (the motor and gearbox) under your layout. The holes in the "arm" allow different "throws" to be achieved for both top and under your layout. Holders for the motor are available from Talking Electronics for $2.50 each and come with screws to hold the servo and for mounting the bracket. Use the tiny screws provided to hold the face-plate in place and the small screws to hold the arm onto the output shaft of the gearbox. You can input AC or DC to the pre-voltage module and the current-limiting resistors are needed to prevent the supply module being overloaded and the other limiting resistors allow the motor to be fed for a longer period of time to achieve the desired rotation. This is the only module on the market with these features. ooooooooooooooooo0000000000000000000oooooooooooooooo

Point

Controller for 4 Motor/Gearbox $45.00usd plus

$12.50 usd shipping

This module converts 4 manual points to

remotely operated points. ooooooooooooooooo0000000000000000000oooooooooooooooo

4-POINT CONTROLLER FOR KATO POINTS

KATO DISTRIBUTION BOARD

$18.00 plus $4.50 postage

Buy Here oooooooooooo000000000000000000oooooooooooooo

FREE

THINGS !!!

|

|

ACTIVATING A POINT |

|

COMPUTER CONTROLLED POINTS

|

|

WIRING A POINT MOTOR |

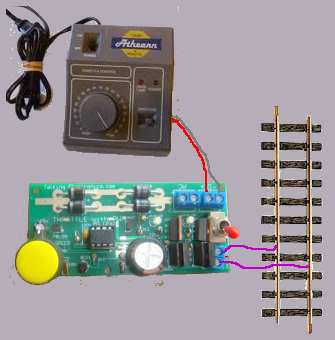

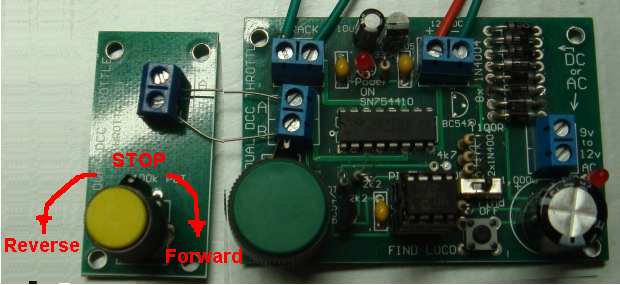

Talking Electronics has produced a number of different TRAIN

THROTTLES.

Most locos take about 300mA to 500mA and need a voltage of about 12v

for full speed.

There are two types of TRAIN THROTTLE:

The 2-Amp POWER SUPPLY project is

HERE You will need a double-pole double-throw toggle switch to reverse the train. Ask for it. $2.50 extra.

oooooooooooooo0000000000000000000000000000oooooooooooooooo

TRAIN THROTTLE No2.

(kit: $18.00 with

leads)

Click

Here

to

order.

The $2.50

plug Pack above was purchased as 12v @ 1 amp. It was easily

opened-up via a screw and clip, to reveal the PC board shown below.

This gives you a very low cost throttle. oooooooooooooo0000000000000000000000000000oooooooooooooooo

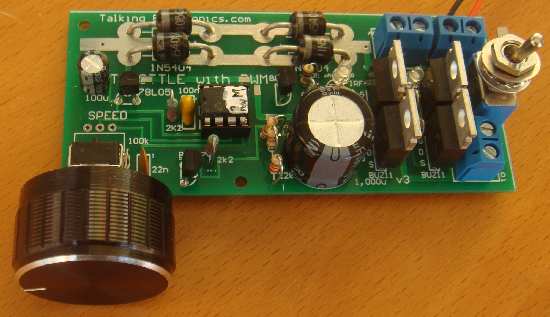

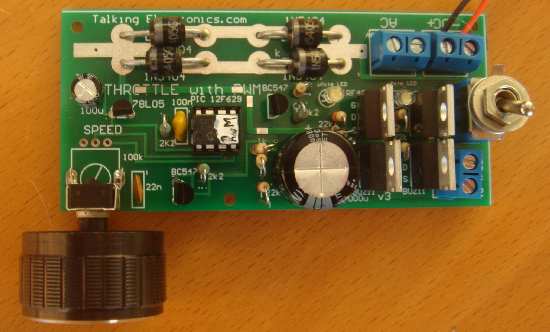

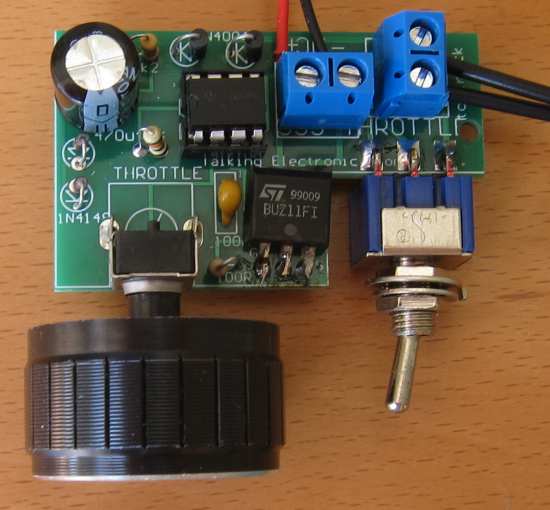

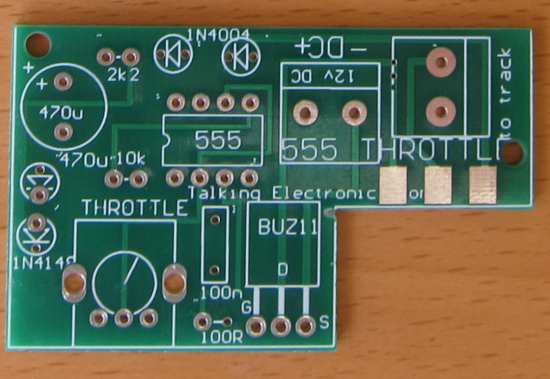

THROTTLE WITH PWM

Kit: $28.50 plus $6.50 postage.

All the

digital signals are controlled (and generated) by the

microcontroller and the pot determines the timing of the

waveform and the activation of the H-bridge. The cost is

the same for either module but you must specify which version you

want. The switch and knob are not attached when posted as the module

must be less than 2cm high for posting in the box we use.

You can request the following type if you do not want to use the rail joiners:

LATEST VERSION

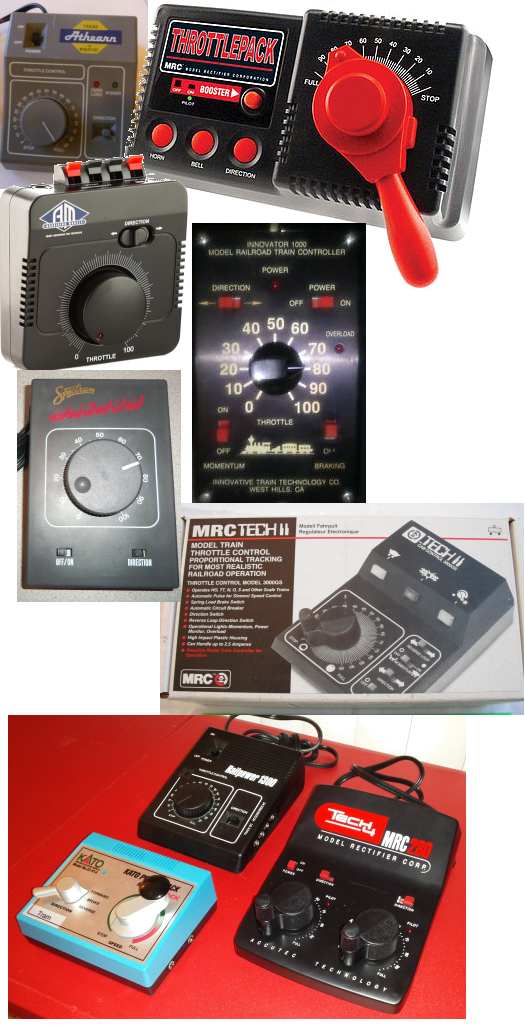

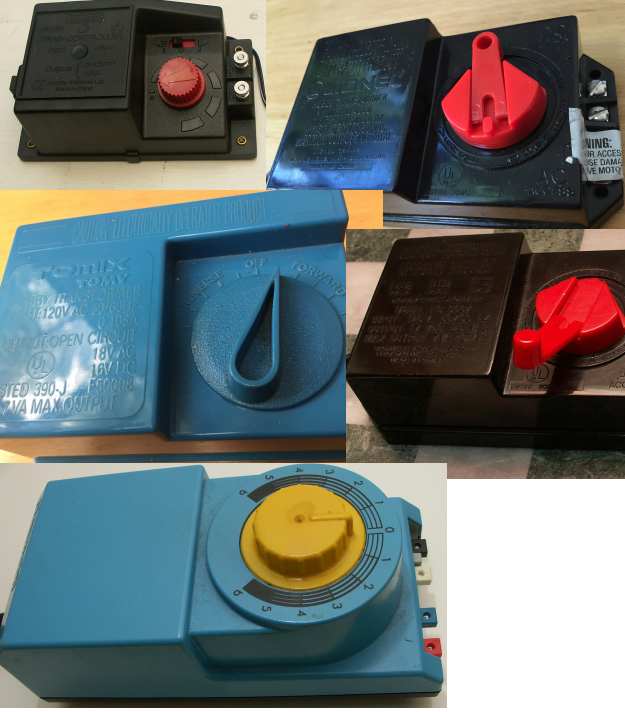

UPGRADE YOUR CONTROLLER

Some of

the following controllers deliver just 7v and some are up to 16v AC

output and/or 16v DC output. They all have forward/reverse on the

control handle so the only improvement you will get by connecting to

the THROTTLE WITH PWM module above is PWM. PWM will allow your train

to start very slowly as the pulses overcome some of the friction by

pulsing the motor with strong bursts and this gets the train moving.

The

Transformer ooooooooooooooooo000000000000000000000ooooooooooo

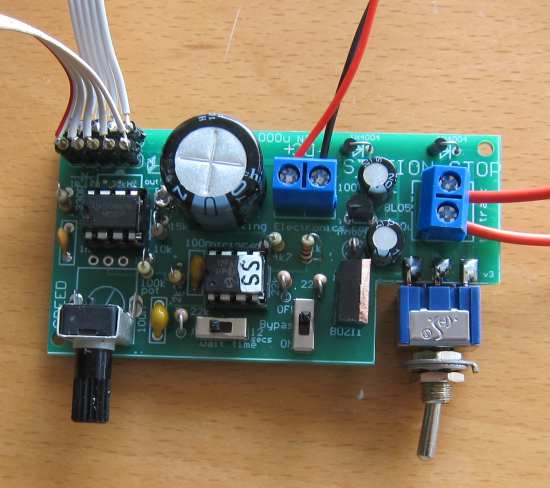

STATION

STOP

MODE 1 |

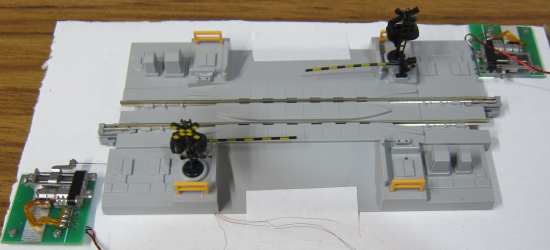

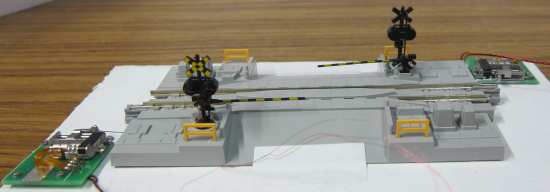

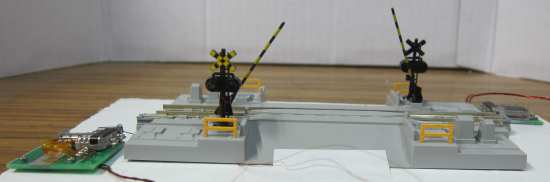

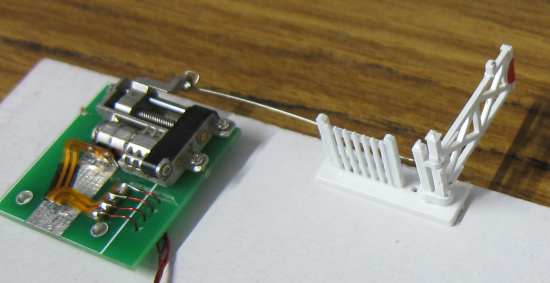

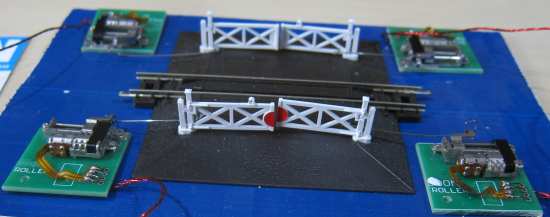

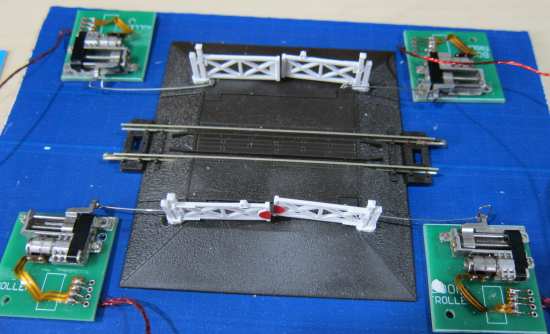

The output of

the servo moves about 70 degrees as this will give the greatest

"throw." You can select the hole on the arm to produce the travel

you want. Here is a set

of gates controlled by 4 servos.

|

Waiting on Printed Circuit boards. The program is written .. . . just the PCB has to be designed. Put your name on the list .

|

DCC

stands for Digital Command Control and basically means you

can control more than one train on the same track.

It

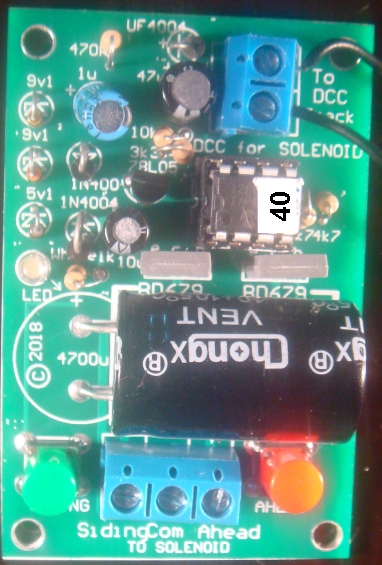

is called: DCC POINT CHANGER for a SOLENOID POINT (with CDU)

and will

operate a Peco or other solenoid point: // ????le

with a relay that you can toggle from the "5 button DCC controller"

shown above. This will allow you to operate station lighting or

motorised animation devices.

The next "add-on" is a DCC module with 5 buttons to operate 1,2,3,4

or 5 DCC points. You will need to buy the $25.00 DCC Point

Controller called a Capacitor Discharge Unit or the DCC Point for

$35.00 using a servo to operate the point. Here are the

modules in more detail:

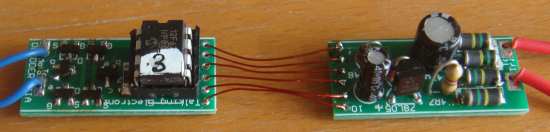

This Dual DCC

controller will control 2 locos at the same time and is an ideal way

to create a DCC set-up. And the cost is just $43.00 AUD plus $6.50

posted worldwide.

ooooooooo0000000000000000000000000000000oooooooooooooooo

This is a 1amp decoder NOT 500mA as most of the advertised small

decoders.

You can turn

a DC Loco into a DCC loco with this universal Motor Decoder for

$18.00 plus $4.50 postage worldwide.

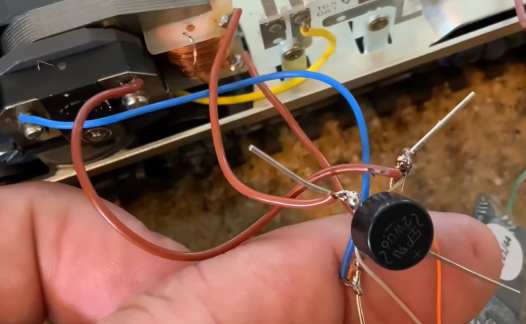

Converting AC Locos Here is a

video showing how to fit a bridge rectifier to deliver pulsating DC

to the filed winding:

The only

problem with fitting a bridge rectifier is this: At low velocity

the energy delivered to the field winding will be very small and

thus the motor will be very weak. The decoder delivers pulses of

energy to the motor and the pulses are actually at full strength but

for a short period of time. You can put 100u to 1,000u electrolytic

across the field winding to see if it improves the performance. |

|

DCC

POINT CHANGER using a servo

You need 4

things:

You will also

need a connection to the track to pick-off the signal< to operate

the DCC Point Changer and also power the servo.

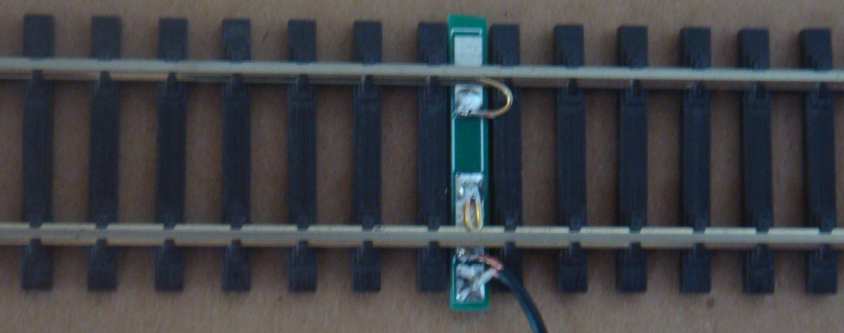

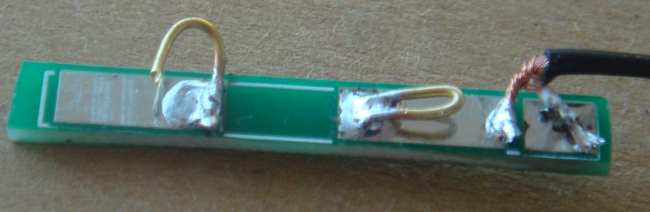

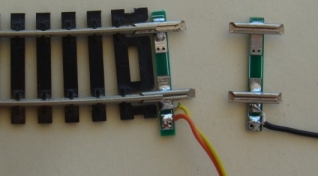

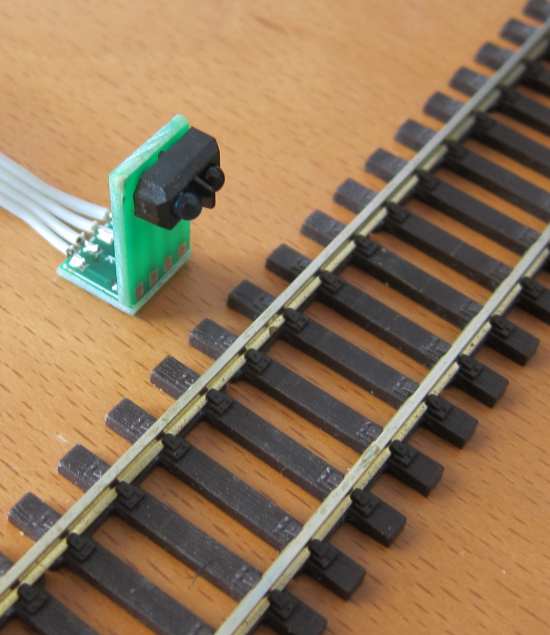

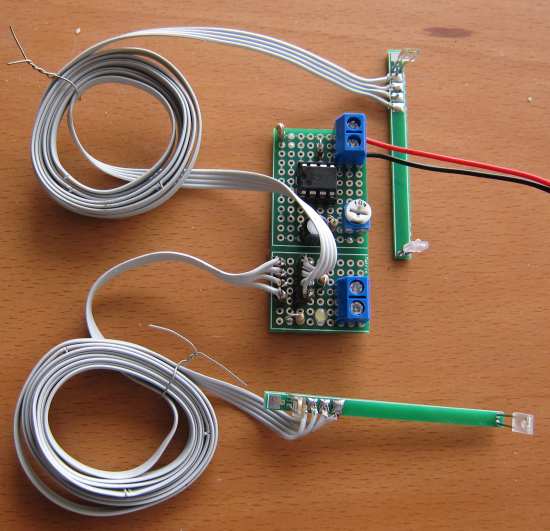

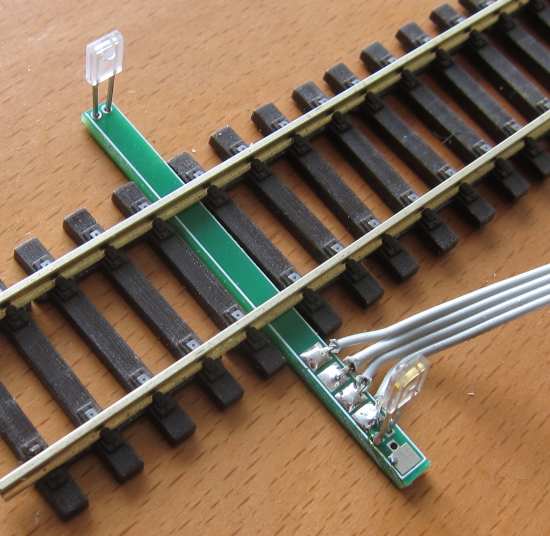

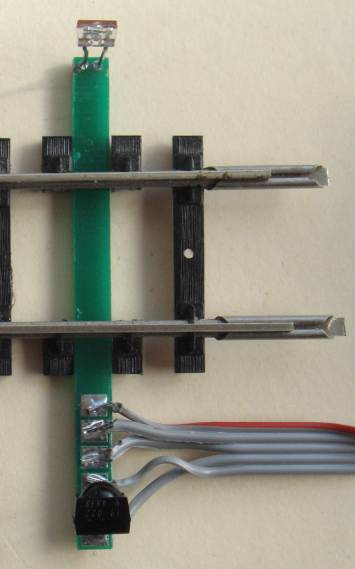

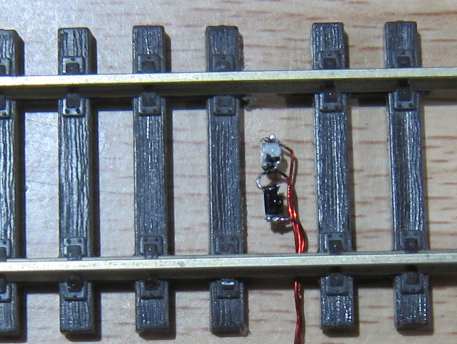

Track Pick-Off MkII.

It

has two springy clips that touch the inner parts of the rails and

make electrical contact. .

YOU

NEED 3 THINGS

SIGNAL PICK-UP oooooooooooooooo000000000000000000000000000000ooooooooooooooooo

DCC

POINT CHANGER for a SOLENOID POINT

The module takes a small amount of current from the track to charges

the 4700u electrolytic to 25v. .

ooooooooooooooooo0000000000000000000ooooooooooooooooo

Your controller

connects to the module

This module fits between your controller and the track. |

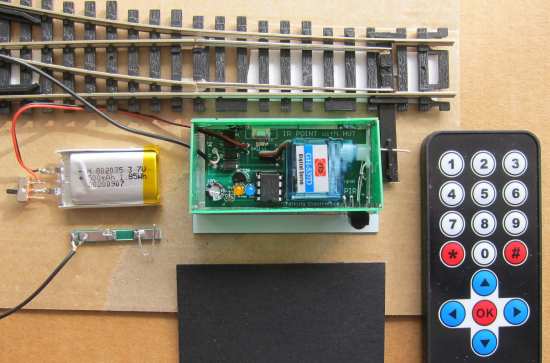

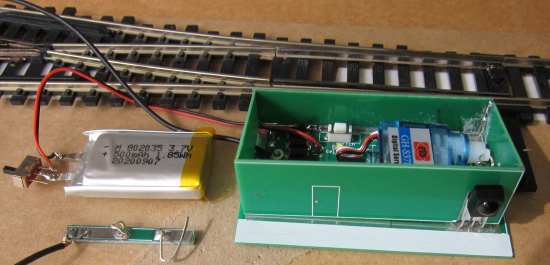

This projects

allows you to use any old IR remote control from a TV or VCR to

control your points.

You can walk around your layout while someone is driving your train

and control the destination of the train.

18/8/2022 |

We have

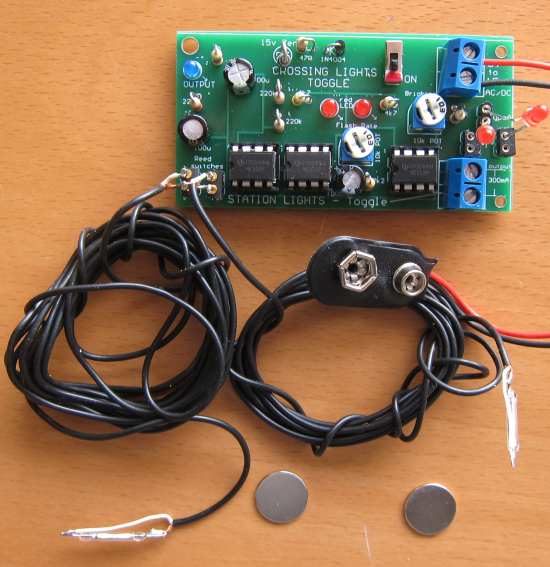

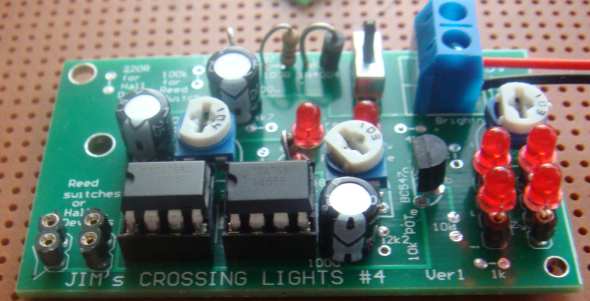

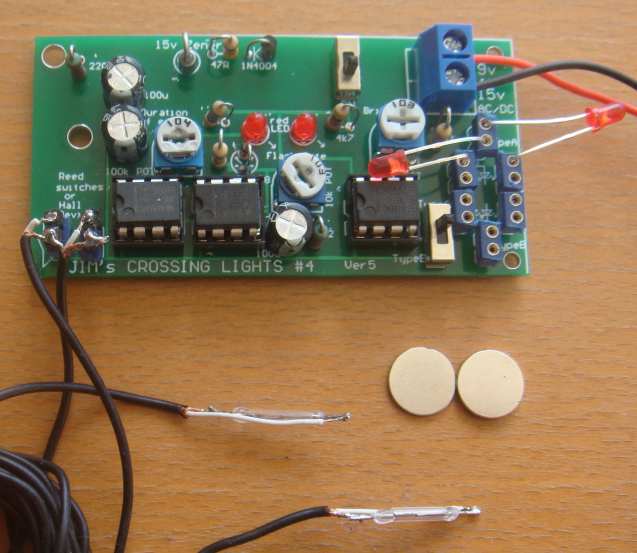

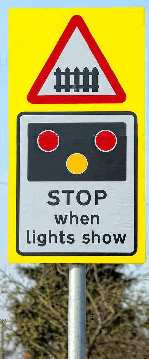

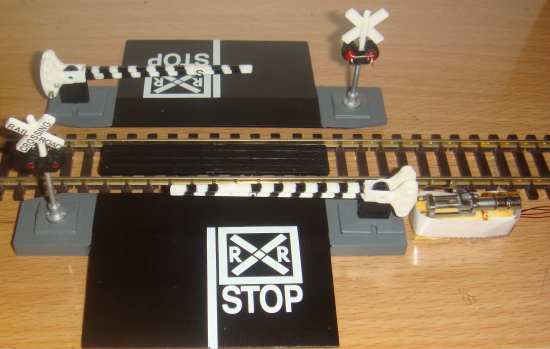

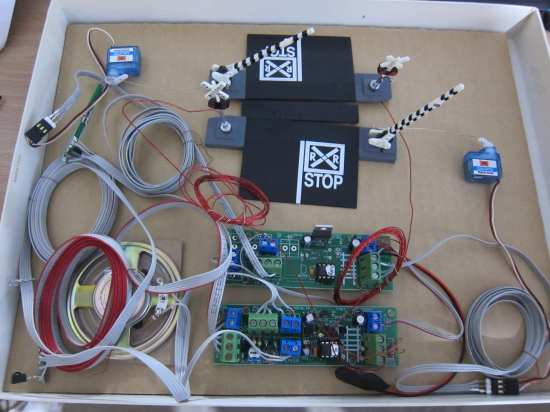

designed 4 different CROSSING LIGHTS MODULES to cover the

different requests from customers.

|

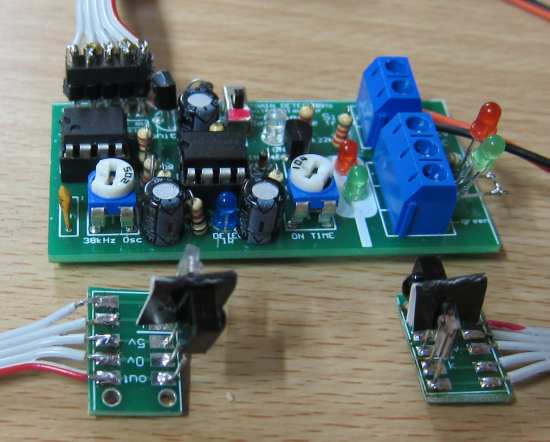

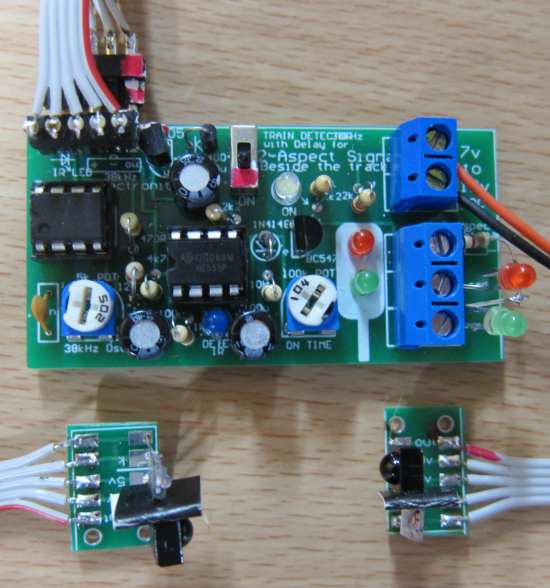

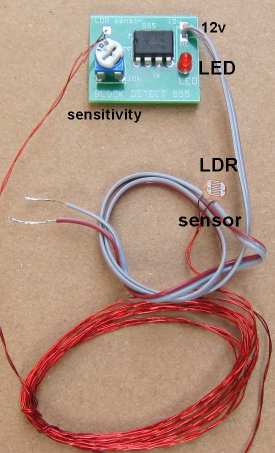

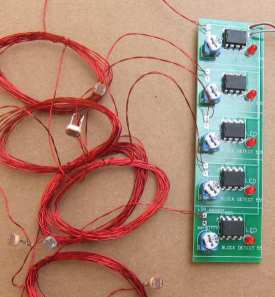

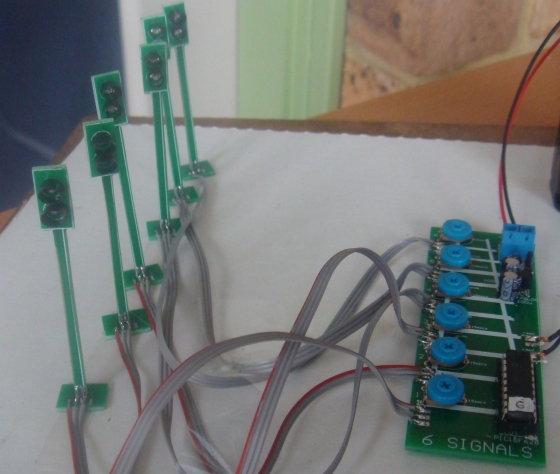

There are 10 different LOCO STOP modules, with different

prices and different features, but they all do the same thing.

|

|

LOCO STOP

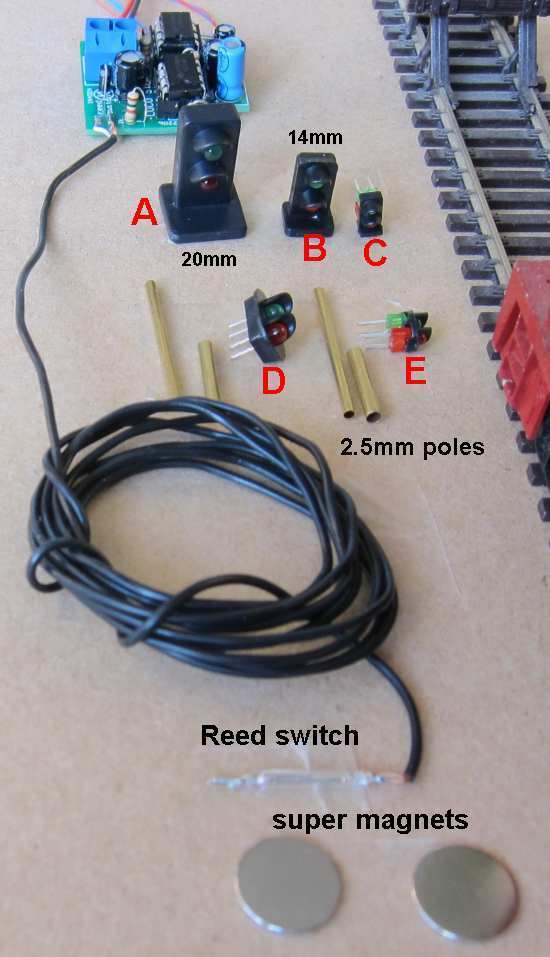

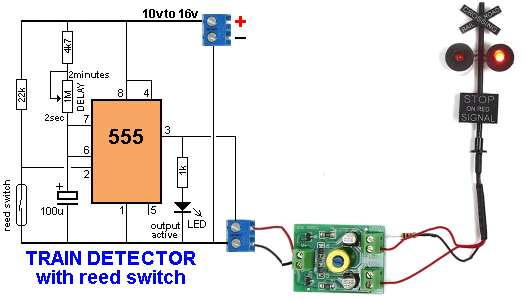

The signal is normally red and when the loco activates the reed switch, the first 555 produces a timing of about 10 seconds so the loco has to stop and wait at the signal and when the time has expired, the second 555 is triggered and the green light shows for 10 seconds and then the red appears again. All this has been done with 2 x 555 IC's. The 2-aspect signal is not a normal signal but comes as a kit from Talking Electronics for $5.00 usd as the LEDs are connected differently to standard models.

The reed switch is placed a short distance in front of the signal so the loco has to stop and wait for green. You can add an accident or track-repair after the signal to provide a purpose for stopping the train.

LOCO STOP

for a 3-aspect signal.

Operating 3-Aspect signal with centre-off

toggle switch

|

|

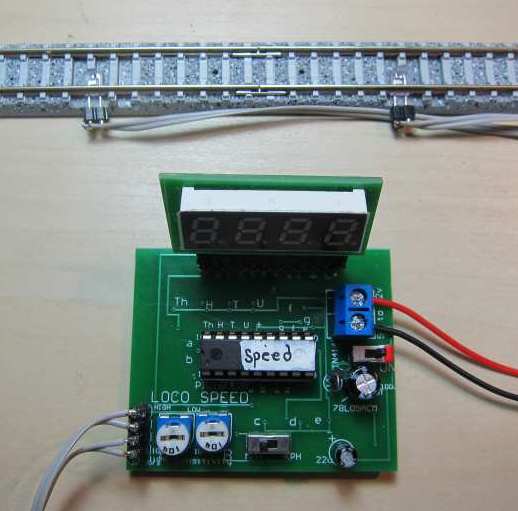

LOCO

SPEED ($55.00usd)

$85.00aud

Plus postage $8.50

|

Talking

Electronics has many different modules to operate points remotely

and you will find them all here, in this article, on the page you

are now viewing. Here are some layouts from readers:

Talking

Electronics has many different modules to operate points remotely

and you will find them all here, in this article, on the page you

are now viewing. Here are some layouts from readers:

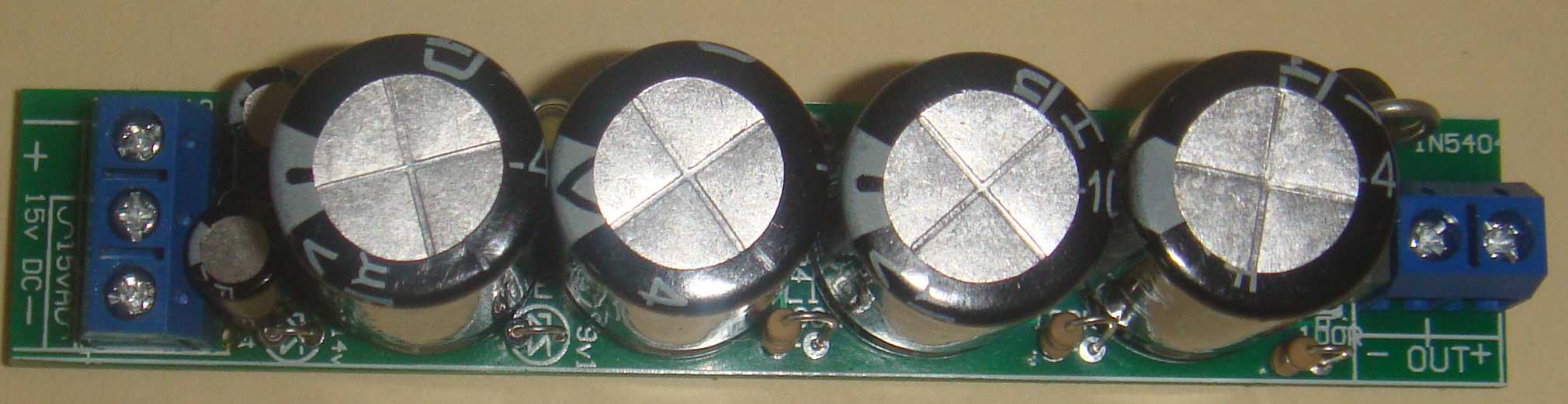

The

input wires (on the right) will accept a DC voltage from 5v to 20v

DC (from a plug pack or wall wort) and produce an output voltage

that has been adjusted by the 10-turn pot. We set the output voltage

to 26.5v so the electrolytics on the CDU module see a voltage of 25v

(after the input diodes).

The

input wires (on the right) will accept a DC voltage from 5v to 20v

DC (from a plug pack or wall wort) and produce an output voltage

that has been adjusted by the 10-turn pot. We set the output voltage

to 26.5v so the electrolytics on the CDU module see a voltage of 25v

(after the input diodes).

This

Switch Machine is fast in operation and very small. It

requires an electronics module for operation (and timing) and

has point indication to show the position of the point. The

timing module TURTLE FAST controls 5 points

This

Switch Machine is fast in operation and very small. It

requires an electronics module for operation (and timing) and

has point indication to show the position of the point. The

timing module TURTLE FAST controls 5 points

Another

Point Controller that is hard to find.

Another

Point Controller that is hard to find.

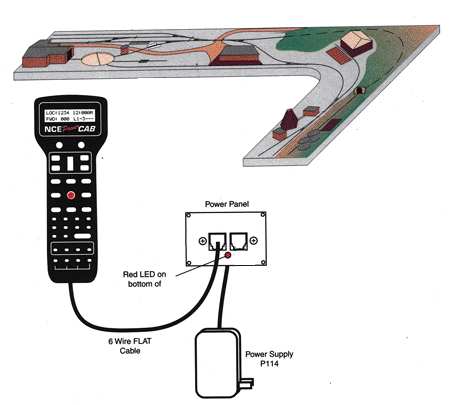

All

our modules work with NCE Power CAB and all controllers that

conform to NMRA signals and codes.

All

our modules work with NCE Power CAB and all controllers that

conform to NMRA signals and codes.

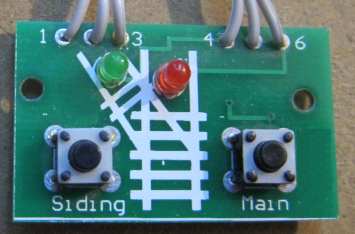

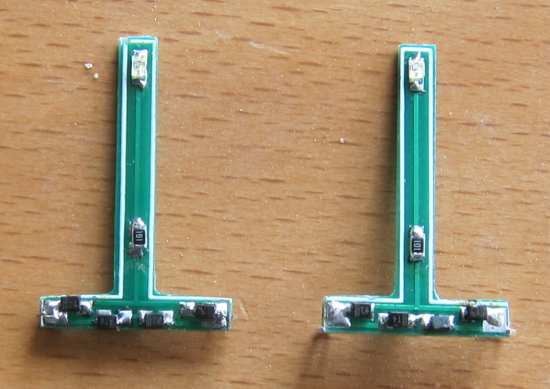

The

control board contains two switches and two LEDs to show

the position of the point.

The

control board contains two switches and two LEDs to show

the position of the point.  The

N-Gauge Manual Point Controller Module

can be used to control a point for a loop of any

"siding."

The

N-Gauge Manual Point Controller Module

can be used to control a point for a loop of any

"siding."  This

layout shows the position of the reed switches to

control the point.

This

layout shows the position of the reed switches to

control the point.

The

signals need to be placed so that S! S2 S3 follow each other

and S4 S5 S6 follows at some other part of the layout.

The

signals need to be placed so that S! S2 S3 follow each other

and S4 S5 S6 follows at some other part of the layout.

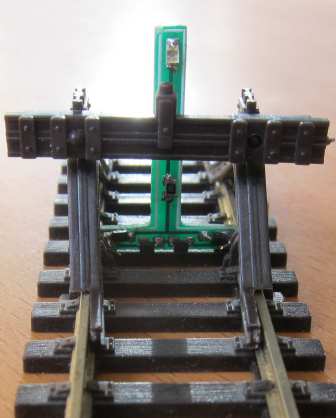

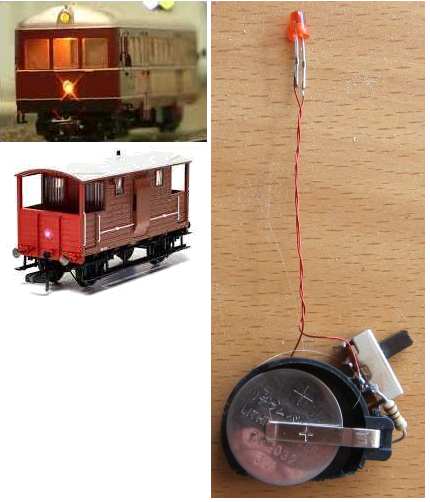

No

batteries or supply needed. The Buffer Warning Lamp

gets its power from the rails via two springy terminals.

No

batteries or supply needed. The Buffer Warning Lamp

gets its power from the rails via two springy terminals.

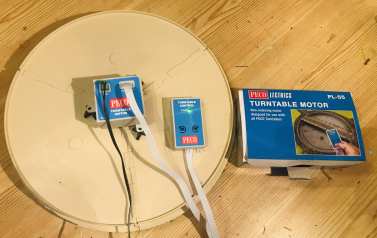

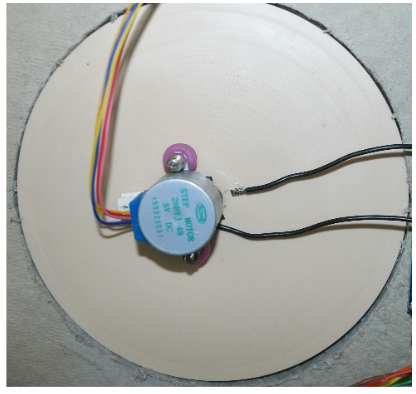

You

need to buy the 28BYJ-48 DC 5V Reduction Step Gear

Stepper Motor from AliExpress for about $3.00 including

shipping from a supplier such as:

You

need to buy the 28BYJ-48 DC 5V Reduction Step Gear

Stepper Motor from AliExpress for about $3.00 including

shipping from a supplier such as: You

will need screws to hold the stepper motor as shown in

the picture opposite.

You

will need screws to hold the stepper motor as shown in

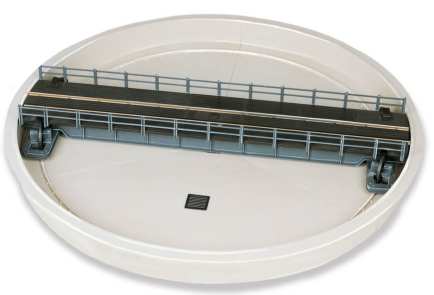

the picture opposite.  This

is the PECO turntable.

This

is the PECO turntable.

If

3rd band is gold, Divide by 10

If

3rd band is gold, Divide by 10